Description

Wet Wipe Packaging Lines

|

1. FULLY AUTOMATIC WET WIPES PACKING LINE SOFT FLOW PACK

2. SEMI-AUTO BUCKET WET WIPES MACHINE |

COMMERCIAL OFFER: – AUTOMATIC WET WIPES LINE – SOFT FLOW PACK

Suited for baby wet wipes 30-120pcs (max height not more than 90mm)

| Sr.

No. |

Description | Qty | Unit

Price |

Total

Price |

| 1 | WET TISSUE FOLDING MACHINE (DOUBLE SHELVING) | 1 set | ||

| 2 | WET TISSUE FLOW PACKING MACHINE | 1 set | ||

| 3 | FULL AUTO PLASTIC LID MACHINE | 1 set | ||

| 4 | Delivery | 1 set | Included | |

| 5 | Project management, installation & commissioning | |||

COMMERCIAL OFFER: – SEMI-AUTO BUCKET WET WIPES MACHINE

| Sr.

No. |

Description | Qty | Unit

Price |

Total

Price |

| 1 | REWIND & SLITTING MACHINE | 1 set | ||

| 2 | SEMI AUTO FILLING MACHINE | 1 set | ||

| 3 | SEMI AUTOMATIC LABELLING MACHINE | 1 set | ||

| 4 | Delivery | 1 set | ||

| 5 | Project management, installation & commissioning | |||

AUTOMATIC WET WIPES LINE – SOFT FLOW PACK

Suited for baby wet wipes 30-120pcs (max height not more than 90mm)

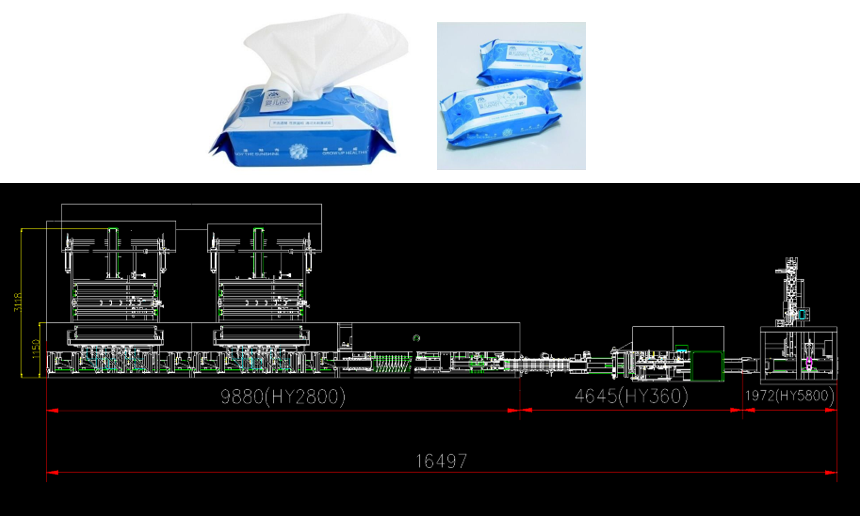

Sample Pack Pics

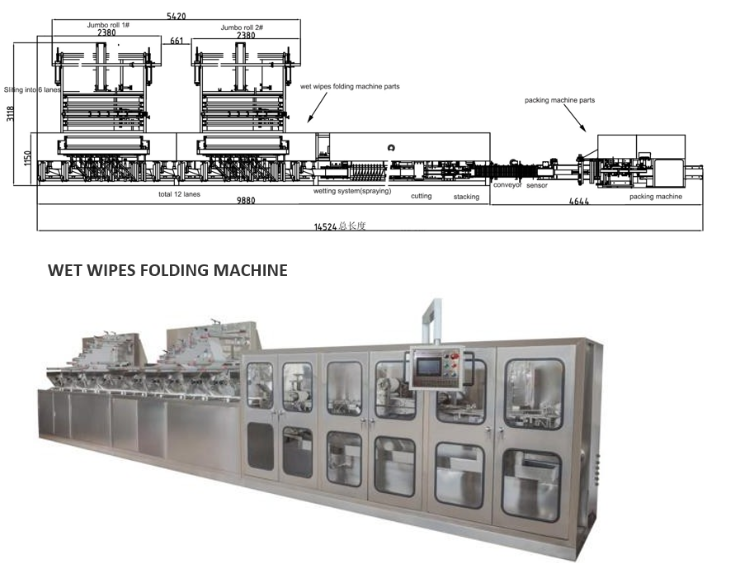

Fully automatic wet tissue folding and packing machine is a machine that can slitting the big jumbo raw material, folding, wetting, cutting in length, stacking then transfer to packing machine for packing. From raw material to finish product all the steps are finished on machine; the process is quick and clean. The folding machine and packing machine can be combine together to be a fully automatic line or can be separated when needed that can max use the machines and make more output.

Features:

Stainless Steel Construction

Automatic Control Servo, semi-servo design, scientific compact structure, easy operation and maintenance.

Temperature of electrical apparatus element on the machine can be adjusted by individually.

Control system: PLC control system, PC color touching screen

Liquid system, liquid tank with agitating function

Main Technical Parameter:

Product type: baby wipes

Production flow: unrolling – folding – wetting – cutting – pile & counting– delivering tissue to packing folding part:

Product speed: 250~350 cuttings/mins Cutting unit:

- Double paper shelves

- 8 lanes /10 lanes /12 lanes, 2 rolls Jumbo rolls

- Raw material roll width :1000~1320mm, diameter: Ø1000mm

Power supply: 380V, 50HZ Power :10KW

Raw material: air-laid paper, non-woven fabric, spun lace

Unfolding size:(140~220) × (150~250) (mm, L×W)

Folding size:(140~220) ×(90~110) (mm, L×W)

Counting way: auto-counting, quantity changeable pile system

Wetting system: presupposed full-automatic quantitative wetting

Wetting accuracy: ±5%

Weight: 5000 kg

Humidification agitating system: double agitating drums with agitator (2 pcs)

Water tank size:800×800(mm, Dia×H) 400 L (2pcs)

Size of the machine: 9600×3300×2000(mm, L×W×H)

Main Technical Parameter:

Production process: connect to the folding machine → feeding wipe automatic →conveying to packing machine → setting packing film → setting window hole label → Central sealing →End sealing and reciprocating cut → Output finished products.

Packaging part:

Product speed:30-60bag/min Diameter of raw film roll:≤380mm

Width of raw film roll:≤420mm

Wrapping material: PP. OPP, PET, PE and all suitable films

Packing length:100-300mm(touch screen settable)

Packing Width:80~130mm(adjustable)

Height of packing:10-100mm (adjustable)

Air requirements:0.5-0.8Mpa 0.01m3/min

Electric power requirement’s 380V 50/60HZ General power:9KW

Dimension of Machine: 5210×1250×2100mm

Standard parts –

Auto waiting conveyor, Date printing unit, punching unit, Two Labelling unit, inserting corner unit, auto-Electrical eye tracking, auto changing packing film, auto changing adhesive label.

Main configuration

The folding machine parts

| No. | ITEM | DESCRIPTION | Qty | REMARKS |

| 1 | PLC host | FX3U-32MT/ES-A | 1 | |

| 2 | PLC host | FX3U-16MT/ES-A | 1 | |

| 3 | Communication module | FX3U-485-BD | 2 | |

| 4 | Communication adapter | FX3U-485ADP | 1 | |

| 5 | Touching screen | GT1055-QSBD-C | 1 | |

| 6 | Battery of touch screen | GT11-50BAT | 1 | |

| 7 | Man-machine communication lines | FX-50DU-CABO | 1 | 5 meters |

| 8 | Frequency converter | FR-A740-5.5K-CHT | 1 | |

| 9 | PC card | FR-A7AP | 1 | |

| 10 | Aluminium barking resistor | 1000W 75 Ω | 1 | |

| 11 | Servo amplifier | MR-J3-200A | 1 | Drawn by rubber covered roller

2000r/min,7.16N8M |

| 12 | servo motor | HF-SP152 | 1 | |

| 13 | Rotary code cable | MR-J3ENSCBL-5M-L | 1 | |

| 14 | Attaching plug | MR-PWCNS4 | 1 | |

| 15 | Servo CN1 plug | MR-J3CN1 | 1 | |

| 16 | Servo amplifier | MR-J3-350A | 1 | Tissue length transportation |

| 17 | Servo motor | HF-SP352 | 1 | 2000r/min,16.7N*M |

| 18 | Rotary code cable | MR-J3ENSCBL-5M-L | 1 | |

| 19 | Attaching plug | MR-PWCNS5 | 1 | |

| 20 | Servo CN1 plug | MR-J3CN1 | 1 | |

| 21 | Servo amplifier | MR-J3-70A | 1 | Tissue holding motor 3000r/min,2.4N*M |

| 22 | Servo motor | HF-KP73 | 2 | |

| 23 | Rotary code cable | MR-J3ENCBL5M-A2-L | 2 | |

| 24 | Attaching plug with cable | MR-PWS1CBL5M-A2-L | 2 | |

| 25 | Servo CN1 plug | MR-J3CN1 | 2 | |

| 26 | Servo amplifier | MR-J3-40A | 2 | Transportation motor 3000r/min,1.3N*M |

| 27 | Servo motor | HF-KP43 | 1 | |

| 28 | Rotary code cable | MR-J3ENCBL5M-A2-L | 1 | |

| 29 | Attaching plug with cable | MR-PWS1CBL5M-A2-L | 1 | |

| 30 | Servo CN1 plug | MR-J3CN1 | 1 |

The packing machine parts

| NO | Item description | Specification | Qty | Remark |

| 1 | Motion controller | JEPMC-MP2300S-E | 1 | Yaskawa |

| 2 | Extended module | R7K4FML-6-DCA32A | 1 | Yaskawa |

| 3 | Servo motor/servo unit | SGMJV-08ADE6S /SGDV-5R5A11A | 5 | Yaskawa 0.75 |

| 4 | Servo motor/servo unit | SGMGV-13ADC61 /SGDV-120A11A | 1 | Yaskawa 1.3kw |

| 5 | Servo motor/servo unit | SGMGV-20ADA61/SGDV-120A11A | 1 | Yaskawa 1.8kw |

| 6 | Servo motor/servo unit | SGMGV-09ADC61/SGDV-7R6A11A | 1 | Yaskawa0.85 kw |

| 7 | Power cable + encoder cable | JZZP-CVM09/JZSP-CVP02-05 | 1 | Yaskawa0.85 |

| 8 | Power cable + encoder cable | JZSP-CMM00-05 JZSP-CMP00-05 | 7 | Yaskawa 0.75 |

| 9 | Power cable + encoder cable | JZSP-CVM30-05 JZSP-CVP02-5 | 2 | Yaskawa 1.8Kw |

| 10 | Communication cable | JEPMC-W6002-05 | 12 | |

| 11 | Terminal resistance | JEPMC-W6022-E | 2 | |

| 12 | Touch panel | Weinview | 1 | 7 inch |

| 13 | Air break switch | LG | 12 | |

| 14 | Residual current circuit breaker | CHINT | 1 | |

| 15 | Contactor (switch) | SCHNEIDER | 1 | |

| 16 | Power switch | M&W | 1 | 350w |

| 17 | Solid state Relay(SSR) | ANV | 6 | |

| 18 | Temperature controller | DTE10P | 1 | |

| 19 | Relay | OMRON | 4 |

FULL-AUTO LID APPLICATOR

Parameter:

| Speed | 55-60pcs/min(eg. Film length at 250mm) | ||

| Film length | 300 mm(the film length will affect the speed) | ||

|

Packing size |

length | width | height |

| 300mm | 45-120mm | 10-80mm | |

| Accuracy | ±1.2 mm | ||

| Voltage require | AC380V 50/60 Hz | ||

| Power | 7.5 KW | ||

| Air Pressure | 0.4 – 0.6MPa 1.0 m³/hour | ||

| Dimension | L 2000 * W 2650 * H 1650 mm | ||

| Weight | 1200 Kg | ||

Main electrical configuration

| No. | Item | Spec & Model | Brand | unit | Qty |

| 1 | SCARA | DRS40L3SS1BN002 CVT | DELTA | set | 1 |

| 2 | Controller #1 | DMV2000-CL2-HS | DELTA | set | 1 |

| 3 | Camera | DMV-CM4MCCL | DELTA | pcs | 1 |

| 4 | Camera Lens | DMV-LN16M06 | DELTA | pcs | 1 |

| 5 | Cables | DMV-CAF03CL | DELTA | set | 1 |

| 6 | Servo system | B2-750W | DELTA | set | 3 |

| 7 | Controller #2 | DVP32ES200T | DELTA | set | 1 |

| 8 | Touch screen | DOPB07E411 | DELTA | pcs | 1 |

| 9 | Hot-melt device | HS-168A | Huangshang | set | 1 |

SEMI-AUTO BUCKET WET WIPES MACHINE

Automatic rewinding and slitting machine

Technical Specifications:

| Rewinding speed | 0-260m/min |

| Suitable raw material | Air laid paper, spun-lace nonwoven, PP |

| Weight of material | 20-120g/m2 |

| Power supply | 380V/3Phase 50/60Hz, 9KW |

| Maximum size of raw material (Jumbo roll) | Diameter 1500 x width 2200mm |

| Maximum size of wet tissue roll | Diameter 60-200mm x width 2200mm (adjustable) |

| Hole punching length | 100-600mm |

| Folding way | “C” shape |

| Air pressure | 0.5Mpa |

| Machine dimension | Length 5380mm x width 3030mm x height 2032mm |

| Machine weight | 5000kg |

| Size of material roll for slitting | Diameter 170-210mm x width 2200mm |

| Width of rolls (after slitting) | 50-220mm |

| Cutting speed | 80-180 cut/min |

SEMI AUTO FILLING MACHINE

Series Single Cylinder Pneumatic / Volumetric Liquid Filling Machine

The Inpakt FLS1 pneumatic volumetric filling machine is a versatile and accurate liquid filling machine.

Self-priming from any floor level tank or drum and is ideal for handling any free-flowing products such as shampoo, detergents, mayonnaise, oils or paints.

The valve is suitable for product feed from floor or elevated tanks.

Standard Features

- Heavy duty pneumatic product cylinder drive system

- Integral 304-grade stainless steel base and cladding for bench or trolley mounting.

- Suitable for warm water hose down

- Wetted parts manufactured from 316-grade stainless steel and food grade engineering plastics

- Product piston fitted with O-ring energized Teflon/HDPE glide ring seal

- All pneumatic flame proof operation suitable for use with flammable products

- Individual fill speed and recharge speed controls

- Inpakt Rotary Product Valve system provides a positive valve seal unaffected by product supply head height

- Product cylinder and valve dismantle by hand for cleaning – no tools require

- Filling accuracy +/- 0.5 or better

SEMI AUTO LABELLING MACHINE

GENERAL CHARACTERISTICS

- No expert knowledge required to set up and operate the machine.

- Ideal for unskilled labour conditions.

- Change over in minutes – no tools or change parts required.

- Backing paper is rolled up on a take up shaft fitted with a quick strip off clamp for easy removal

Labels are applied partly or full wrap. - Robust construction – made from heavy duty steel and finished in durable electroplated zinc.

- Reliable and trouble-free service over many years.

- Minimal maintenance required – keep clean.

- Labels can be die cut, butt cut or transparent.

- Custom made for all size containers

- 220V single phase