Description

Fully Automatic Wet Wipes Packing Machine

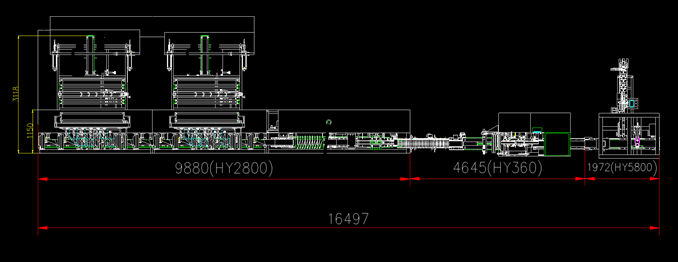

| MACHINE LIST | |

| 1 | Wet tissue folding Machine (two big shelves) |

| 2 | Wet tissue packing Machine |

| 3 | Full auto plastic lid machine |

Automatic wet tissue folding and packing machine is a machine that can slitting the big jumbo raw material, folding, liquid filling, cutting in length, stacking then transfer to packing machine for packing. From raw material to finish product all the steps are finished on machine, the process is quick and clean. The folding machine and packing machine can be combine together to be a full automatic line or can be separated when needed that can max use the machines and make more output.

Features:

- the main of the machine is made by stainless

- Automatic Control Servo ,semi-servo design, scientific compact structure, easy operation and

- The temperature of electrical apparatus element on the machine can be adjusted by themselves.

- Control system: PLC control system , PC color touching screen

- Liquid system:the liquid tank with agitating function.

WET WIPES FOLDING MACHINE PARTS

Main Technical Parameter:

Product type: baby wipes

Production flow:

unrolling – folding – wetting – cutting – pile & counting– delivering tissue to packing

Folding part:

Product speed: 250~350 cuttings/mins

Cutting unit: double paper shelves

- 8 lanes /10 lanes /12 lanes, 2 rolls Jumbo rolls

- raw material roll width :1000~1320mm, diameter: Ø1000mm

- Power supply: 380V, 50HZ

- Power :10KW

- Raw material: air-laid paper, non-woven fabric, spun lace

- Unfolding size:(140~220) ×(150~250) (mm, L×W)

- Folding size:(140~220) ×(90~110) (mm, L×W)

- Counting way: auto-counting, quantity changeable pile system

- Wetting system: presupposed full-automatic quantitative wetting

- Wetting accuracy: ±5%

- Weight: 5000 kg

- Humidification agitating system: double agitating drums with agitator (2 pcs)

- Water tank size:800×800(mm, Dia×H) 400 L (2pcs)

- Size of the machine: 9600×3300×2000(mm, L×W×H)

WET WIPES PACKING MACHINE

Main Technical Parameter:

Production process:

connect to the folding machine → feeding wipe automatic →conveying to packing machine → setting packing film → setting window hole label → Central sealing →End sealing and reciprocating cut → Output finished products.

Packaging part:

- Product speed:30-60bag/min

- Diameter of raw film roll:≤380mm

- Width of raw film roll:≤420mm

- Wrapping material: PP. OPP, PET, PE and all suitable films Packing length:100-300mm(touch screen settable)

- Packing Width:80~130mm(adjustable)

- Height of packing:10-100mm (adjustable)

- Air requirements:0.5-0.8Mpa 0.01m3/min

- Electric power requirements 380V 50/60HZ

- General power:9KW

- Dimension of Machine: 5210×1250×2100mm

- Standard equipment: Auto waiting conveyor, Date printing unit Punching unit, two Labelling unit, Inserting corner unit, auto-Electrical eye tracking and auto changing packing film, auto changing adhesive label.

Sample:

Main configuration

The folding machine parts

| No. | ITEM | DESCRIPTION | Qty | REMARKS |

| 1 | PLC host | FX3U-32MT/ES-A | 1 | |

| 2 | PLC host | FX3U-16MT/ES-A | 1 | |

| 3 | Communication module | FX3U-485-BD | 2 | |

| 4 | Communication adapter | FX3U-485ADP | 1 | |

| 5 | Touching screen | GT1055-QSBD-C | 1 | |

| 6 | Battery of touch screen | GT11-50BAT | 1 | |

| 7 | Man-machine communication lines | FX-50DU-CABO | 1 | 5 meters |

| 8 | Frequency converter | FR-A740-5.5K-CHT | 1 | |

| 9 | PC card | FR-A7AP | 1 | |

| 10 | Aluminum barking resistor | 1000W 75 Ω | 1 | |

| 11 | Servo amplifier | MR-J3-200A | 1 | Drawn by rubber covered roller

2000r/min,7.16N8M |

| 12 | servo motor | HF-SP152 | 1 | |

| 13 | Rotary code cable | MR-J3ENSCBL-5M-L | 1 | |

| 14 | Attaching plug | MR-PWCNS4 | 1 | |

| 15 | Servo CN1 plug | MR-J3CN1 | 1 | |

| 16 | Servo amplifier | MR-J3-350A | 1 | Tissue length transportation |

| 17 | Servo motor | HF-SP352 | 1 | 2000r/min,16.7N*M |

| 18 | Rotary code cable | MR-J3ENSCBL-5M-L | 1 | |

| 19 | Attaching plug | MR-PWCNS5 | 1 | |

| 20 | Servo CN1 plug | MR-J3CN1 | 1 | |

| 21 | Servo amplifier | MR-J3-70A | 1 | Tissue holding motor 3000r/min,2.4N*M |

| 22 | Servo motor | HF-KP73 | 2 | |

| 23 | Rotary code cable | MR-J3ENCBL5M-A2-L | 2 | |

| 24 | Attaching plug with cable | MR-PWS1CBL5M-A2-L | 2 | |

| 25 | Servo CN1 plug | MR-J3CN1 | 2 | |

| 26 | Servo amplifier | MR-J3-40A | 2 | Transportation motor 3000r/min,1.3N*M |

| 27 | Servo motor | HF-KP43 | 1 | |

| 28 | Rotary code cable | MR-J3ENCBL5M-A2-L | 1 | |

| 29 | Attaching plug with cable | MR-PWS1CBL5M-A2-L | 1 | |

| 30 | Servo CN1 plug | MR-J3CN1 | 1 |

The packing machine parts

| NO | Item description | Specification | Qty | Remark |

| 1 | Motion controller | JEPMC-MP2300S-E | 1 | Yaskawa |

| 2 | Extended module | R7K4FML-6-DCA32A | 1 | Yaskawa |

| 3 | Servo motor/servo unit | SGMJV-08ADE6S /SGDV-5R5A11A | 5 | Yaskawa 0.75 |

| 4 | Servo motor/servo unit | SGMGV-13ADC61 /SGDV-120A11A | 1 | Yaskawa 1.3kw |

| 5 | Servo motor/servo unit | SGMGV-20ADA61/SGDV-120A11A | 1 | Yaskawa 1.8kw |

| 6 | Servo motor/servo unit | SGMGV-09ADC61/SGDV-7R6A11A | 1 | Yaskawa0.85 kw |

| 7 | Power cable + encoder cable | JZZP-CVM09/JZSP-CVP02-05 | 1 | Yaskawa0.85 |

| 8 | Power cable + encoder cable | JZSP-CMM00-05 JZSP-CMP00-05 | 7 | Yaskawa 0.75 |

| 9 | Power cable + encoder cable | JZSP-CVM30-05 JZSP-CVP02-5 | 2 | Yaskawa 1.8Kw |

| 10 | Communication cable | JEPMC-W6002-05 | 12 | |

| 11 | Terminal resistance | JEPMC-W6022-E | 2 | |

| 12 | Touch panel | Weinview | 1 | 7 inch |

| 13 | Air break switch | LG | 12 | |

| 14 | Residual current circuit breaker | CHINT | 1 | |

| 15 | Contactor (switch) | SCHNEIDER | 1 | |

| 16 | Power switch | M&W | 1 | 350w |

| 17 | Solid state Relay(SSR) | ANV | 6 | |

| 18 | Temperature controller | DTE10P | 1 | |

| 19 | Relay | OMRON | 4 |

Full-auto Lid Applicator

Parameter

| Speed | 55-60pcs/min(eg. Film length at 250mm) | ||

| Film length | 300 mm(the film length will affect the speed) | ||

|

Packing size |

length | width | height |

| 300mm | 45-120mm | 10-80mm | |

| Accuarcy | ±1.2 mm | ||

| Voltage require | AC380V 50/60 Hz | ||

| Power | 7.5 KW | ||

| Air Pressure | 0.4 – 0.6MPa 1.0 m³/hour | ||

| Dimension | L 2000 * W 2650 * H 1650 mm | ||

| Weight | 1200 Kg | ||