Description

Automatic Canister Wipes Production Line (50-60CPM)

This production line is used to produce and package canister wipes automatically and consists of the following processes:

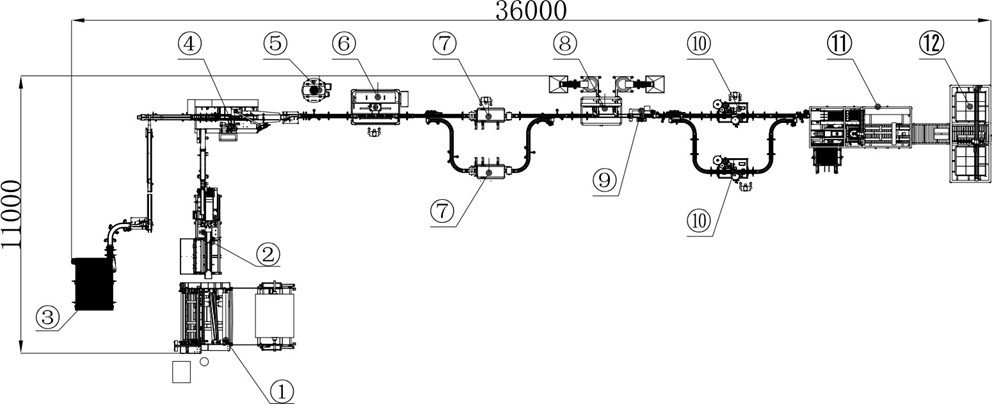

Layout

| # | Description |

| 1 | Automatic Rewinding Machine |

| 2 | Automatic Slitting Machine |

| 3 | Canister Unscrambler |

| 4 | Automatic Wipes Stuffing Machine |

| 5 | Stainless Steel Tank |

| 6 | Automatic Multi-head Filling Machine |

| 7 | Automatic Canisters Sealing Machine |

| 8 | Automatic Caps Feeder |

| 9 | Automatic Canisters Capping Machine |

| 10 | Automatic Canisters Labeling Machine |

| 11 | Automatic Corrugated Box Packing Machine |

| 12 | Automatic Palletizing Machine |

1: Automatic Rewinding and Slitting Machine

Technical Specifications:

| Rewinding speed | 0-260m/min |

| Suitable raw material | Air laid paper, spun-lace nonwoven, PP |

| Weight of material | 20-120g/m2 |

| Power supply | 380V/3Phase 50/60Hz, 9KW |

| Maximum size of raw material (Jumbo roll) | Diameter 1500 x width 2200mm |

| Maximum size of wet tissue roll | Diameter 60-130 x width 2200mm (adjustable) |

| Hole punching length | 100-600mm |

| Folding way | “C” shape |

| Air pressure | 0.5Mpa |

| Machine dimension | Length 5380mm x width 3030mm x height 2032mm |

| Machine weight | 3000kg |

| Size of material roll for slitting | Diameter 60-130 x width 2200mm |

| Width of rolls (after slitting) | 50-220mm |

| Cutting speed | 80-180 cut/min |

2: Automatic Wipes Stuffing Machine

Technical Specifications:

| Stuffing speed | 30-70 canisters/min |

| Max canister size | Diameter 110 x height 220mm |

| Weight of material | 20-120g/m2 |

| Power supply | 380V/3Phase 50/60Hz, 2.74KW |

| Air pressure | 0.5-0.8Mpa |

| Air consumption | 120-160L/min |

| Machine dimension | Length 3250 x width 1650 x height 1800mm

length 2000 x width 260 x height 1200mm |

| Machine weight | 1500kg |

3: Automatic Multi-head Filling Machine (with stainless steel tank)

Technical Specifications:

| Filling speed | 50-70 canisters/min |

| Max canister size | Diameter 110 x height 175mm |

| Filling range | 50 – 200ml |

| Applicable materials | PE film, aluminum film |

| Power supply | 380V/3Phase 50/60Hz, 4KW |

| Machine dimension | 3000mm*1050mm*1887mm |

| Machine weight | 600kg |

4: Automatic Canister Sealing Machine x 2 sets

Technical Specifications:

| Supply Power | 220V 50/60Hz |

| Heat sealing power | 0.5 – 1KW |

| Sealing diameter | 50 – 250mm |

| Application material | Aluminum foil, PP, PE, PET, PS |

| Film size | About 2-3mm bigger than the cans diameter |

| Air pressure | 0.3-0.5Mpa |

| Production speed | 25 – 30 canisters/min x 2 |

| Machine dimension | Length 2000 x width 500 x height 1600mm |

| Machine weight | 260kg |

5: Automatic Canisters Capping Machine

Technical Specifications:

| Production speed | 50 – 60 canisters/min |

| Canister diameter | 70-130mm |

| Power supply | 380V/3phase 50/60Hz, 2KW |

| Machine size | Length 3100 x width 1500 x height 2500mm |

| Air pressure | < 0.5Mpa |

| Weight of machine | 650kg |

6: Automatic Canisters Labeling Machine x 2 sets

Technical Specifications:

| Labeling speed | 40-50 canister/min x 2 sets |

| Canister size | Diameter 80 x height 175mm |

| Power supply | 220V 50/60Hz, 2KW |

| Labeling accuracy | ± 1.0mm |

| Label range | width ≤ 180mm |

| Machine dimension | Length 2000 x width 1155 x height 1450mm |

| Machine weight | 450kg |

7: Automatic Canisters Case Packing Machine x 1sets

Main parameter:

| Model | ZY-CP600 |

| Performance of machine | About 400-500 cases/hour

(this project, about 8 case/min) |

| Performance of manipulator | Max 12 times/min (each one.) |

| Box Sealing method | Tape sealing or hot melt sealing |

|

Paperboard box |

Min 300*200*180mm |

| Max 500*400*350mm | |

| Power supply | AC 380V 50/60HZ 7.5KW |

| Air supply | 0.6-1.0 Mpas |

| Air consumption | <1m3/min |

| Machine size (L*W*H) | About 4000*2200*2500mm |

| Weight | 3000(kg) |

8:Automatic Canisters Palletizing Machine x 1sets

Parameter:

| Power supply | 380V 50/60Hz |

| Suitable pallet | 100-120 ×100-120(mm) |

| Palletizing speed | 10-30 cases/min |

| Manipulator Max loading | 30-40KG |

| Palletizing Height | max 1600mm ( customized) |