Description

Oil Filling and Packing Automated Lines

Figure 1: Bottle Sorter

Figure 2: Filling & Capping Tri-Block

Figure 3: Filing Part

Figure 4: Filling Cycle

Figure 5: Capping Unit

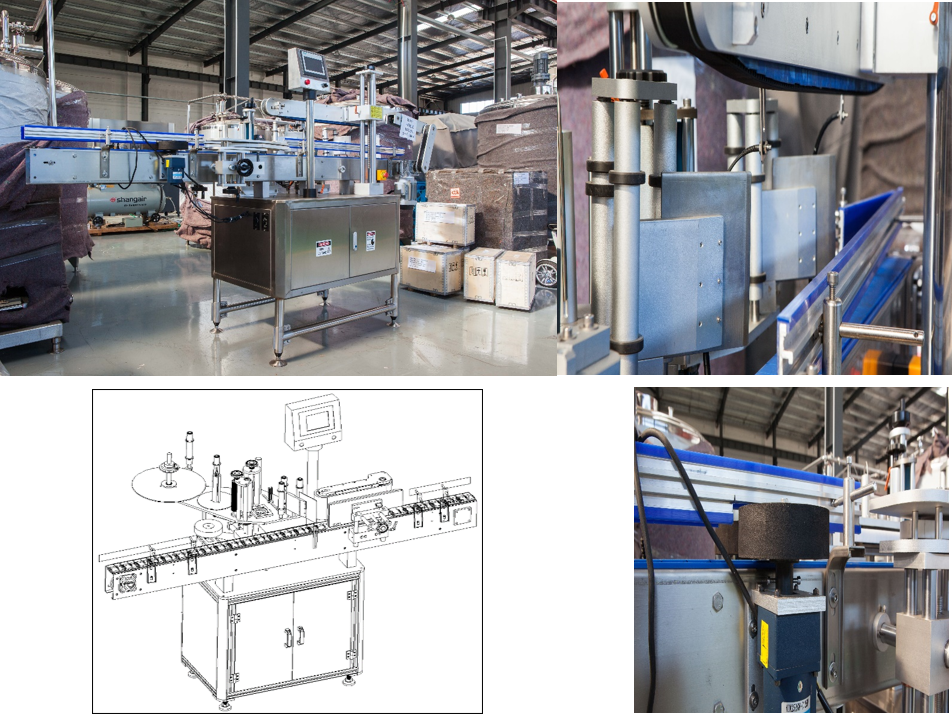

Figure 6: Cap Hopper

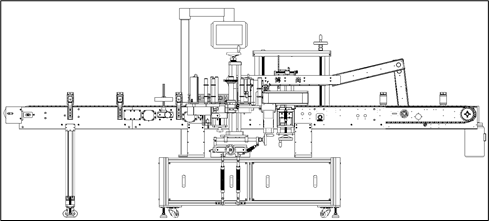

Figure 7: Adhesive Labeling

Figure 8: High-Speed Double Side Adhesive Labeler

Figure 9: Date/Batch Coding Machine

Figure 10:Automatic Carton Sealer

Figure 11: Automatic Carton Erector

Figure 12:Carton Packing Machine

Figure 13: Automatic Carton Sealer

Figure 14: Conveyor Belt and Accumulation/Buffering

Project Scope

Supply of automated filling and packaging equipment for cooking oil for the following SKUs:

- 375ml, 500ml & 750 ml – 24000BPH (375ml)

- 5 L & 2L – 70000BPH

- 4L & 5L – 2500BPH

- 20L – 625BPH

The quote details the equipment for all four lines. These are complete filling and packaging lines that can be installed in four phases, starting with the most critical line-with fast moving Stock Keeping Units( SKUs). This is based on the 100% Machine Rated Capacity(MRC), giving maximum Bottles Per Hour( BPH) for each line.

Inpakt Group provides a comprehensive Turnkey solution from:

- Equipment specifications, Design and Factory Acceptance Tests( FAT)

- Procurement and logistics

- Installations and Commissioning

- Performance Acceptance Testing( PAT)

- Training and After Sales Support

- Support Assurance Program

Oil Filling and Packaging Line Equipment Pictures

Line 1-375ml 500ml 750ml

Bottle sorter

Line 1 Bottle Sorter(BS) Specifications

- The main motor reducer uses a torque limiting mechanism to prevent damage to the machine in the event of a failure.

- Configure the bottle pushing and ejecting mechanism twice to ensure that there are bottles at each bottle dropping station and improve the efficiency of bottle discharging.

- Configure the bottle-hung neck conveying air duct to prevent the bottle from tipping over during conveying.

- A broken bottle rejection mechanism is provided.

- It has a bottle jam detector which automatically stops and alarms when a bottle jam occurs.

- A bottle presence/absence detector is provided to send a working signal to the elevator and the elevator will automatically replenish the bottle.

- A photoelectric switch is installed on the bottle conveying duct to control the start and stop of the bottle unscrambler.

- The bottle unscrambler is equipped with a grease nipple which can easily fill the gear bearing and Cam with lubricating oil.

- Equipped with maintenance door and mold replacement door.

- The main electrical components (inverter PLC photoelectric switch relay) use MITSUBISHI OMRON SIEMENS and other components.

- The gas circuit system uses German FESTO products.

Technical Parameters

| Model | IN-LP2600 |

| Bottle sorting heads: | / |

| Compressed air pressure: | 0.7Mpa |

| Air consumption: | 1.5M3/min |

| Bottle dimension: | Bottle diameter: 50-90 bottle height: 165-290 |

| Main motor power: | 2.2 kW |

| Lifting motor power: | 0.75 kW |

| Weight: | 3000Kg |

| Dimension: | D2360*H2060mm |

Components List

| Items | Supplier Origin |

| PLC | Siemens Germany |

| Touch screen | |

| Contactor | Siemens Germany |

| Thermal relay | |

| Switches | |

| Photoelectric electric sensor | Autonics S. Korea |

| Pneumatic components | Airtac Taiwan |

Filling and Capping Tri-Block Details

- Welded by SUS304 Product contact is SUS304 food grade;(SUS316 for option)

- High-efficiency rinsing-nozzles can spray water to any part inside the bottle.

- Corrosion-resistant bearings from NSK or SKF.

- Mechanical valve filling flow meter filling weighing filling or laser positioning filling as an option

- Open design for gear transmission.

- Bottle transporting system is neck-holding design.

- Equipped with VFD control more energy-saving.

- PLC control system is equipped.

- All electric components are supplied by the world-famous companies.

- French “ZALKIN” capping technology is used for higher performance.

- Capping torque can be adjusted accordingly.

- Cap absence can be detected and up-side down caps can be picked out.

- Online cap sterilizer as an option

Technical Components

| Model: | IN-GF60-15 |

| Capacity: | 24000 B/H (500ml) |

| Bottle height: | 120-310 mm |

| Bottle diameter: | 50-96 mm |

| Bottle mouth diameter: | 26-40 mm |

| Bottle type: | PET bottle |

| Cap type: | Flat cap / Sports cap |

| Filling heads: | 60 |

| Filling temperature: | ≤ 5℃ |

| Filling pressure: | 02-04 Mpa |

| Flow velocity of the valve: | 120-150 ml/s |

| Filling valve: | SUS316 |

| Product reservoir tank: | SUS304 |

| Capping heads: | 15 |

| Capping torque: | 06-28 Nm (adjustable) |

| Main motor power: | 3 kW AC 400V 50Hz IP55 |

| Installation power: | 8 kW |

| Power supply: | 415V 50HZ |

| Consumption of compressed air: | 08 m³/min (06MPa/H) |

| Consumption of aseptic water: | 35 m³/h (02-025Mpa) |

| Dimension: | 4500*3000*2200 mm |

| Weight: | 7500 Kg |

Components List

| Items | Supplier Origin |

| PLC | Siemens Germany |

| Touch screen | |

| VFD | Siemens Germany |

| Contactor | Siemens Germany |

| Thermal relay | |

| Switches | |

| Micro relay | |

| Photoelectric electric sensor | Autonic S. Korea |

| Pneumatic cylinder | Airtac Taiwan |

| Electromagnetic valve | |

| Air filter pressure reducing valve oil mister | |

| pressure adjusting valve | |

| Rinsing / Filling Pump | Grundfos Denmark |

Detailed description

Features

- Non-contact filling

- Weighing filling technology

- Neck-holding design to ensure bottle neck and the filling valve contact seamlessly

- Bottle-explosion-proof( Bottle burst procedure)device installed the filling valve can turn off automatically

- The filler can adjust the height to match the different-height bottles (have maximum and minimum height protection)

- Open style gear transmission highly efficient low noise long life-service easy maintenance

- The motor is adjusted by the inverter stepless frequency conversion speed regulation

- Bottle transporting system has simple structure short changeover time to fit different bottles Bottom-holding method for transporting

- PLC system-controlled errors can be displayed on the screen such as: bottle jammed cap absence

- Bottle presence/absence sensor means if there is no bottle then there is no filling.

- The liquid level inside the filling tank is monitored by the sensor ensuring stable filling

• The key electric parts are made by the world-famous companies - Sealing rings on the filler are manufactured in Europe

Capping Part

Features

- Caps will be unscrambled in the silo the amount is monitored

- Capping torque can be adjusted accordingly

- A flip-over adjuster installed on the slide to avoid up-side-down caps

- Two photoelectric sensors installed on the slide to alarm the cap-absence

- The capper can adjust the height to match the different-height bottles (have maximum and minimum height protection)

Cap hopper (for HDPE cap)

Features

- No damage on the plastic cap

- Transparent PC board for cap sorting

- Equipment with AC motor and speed reducer

- Indicator light for cap absence

- Upside-down caps will be picked out and sent back to the hopper

Technical Parameters

| Model: | IN-SGJ |

| Cap type: | Flat cap / sports cap |

| Material: | SUS 304 |

| Conveying capacity: | 20000 caps/h |

| Power: | 037 kW |

Adhesive labeler

Description

The product is transported by the upper conveyor belt (or manual loading) → conveyor belt conveyor belt → material distribution → electric eye detection → the feeder mechanism receives the electric eye signal to send the label → the label is instantly sent to the product to be labelled part → pressure label Roller pressure mark→ Finished product through plate chain conveyor output.

The main processes of labeling and labeling are sequentially refined into:

Process: Infeed bottle → pre-position → label feed → body label → face label → neck label → finish

Machine composition

A: Labeling station

- Yaskawa Micro inertia servo motor

- Yaskawa servo amplifier

- Siemens Programmable Controller (PLC)

- Mitsubishi/Siemens human machine interface (Chinese and English bilingual operation interface)

- German SICK or American LION label sensor

- Japan KEYENCE product detection photoelectric switch

B: mechanical part

- Spindle mechanism: NORD AC motor

- Danfoss frequency converter speed regulation

- Gear transmission system

- Cam pressing bottle system

- Presser transmission system

- Bottle holding base transmission system

- Height regulation system

- Bottle feeding mechanism: special non-damage bottle star wheel connected with the main turntable gear adjust the spacing

- Special inlet star wheel connected with main turntable gear main turntable transition mechanism

- Chain width 826 mm

- Bottle discharging star wheel: connected with the main turntable gear the bottle is smoothly fed into the conveyor line

- Label pressing mechanism: sponge spring steel plate combination Teflon patch

- Bottle guiding mechanism: double coordinate wear-resistant casting nylon

C Equipment safety protection

Safety protection: Close the protective door when the equipment is running to prevent injury to the operator.

Missing alarm: the label will be used when the alarm prompts to remind the operator to prepare to replace the label.

Bottle shortage alarm: When bottle shortage is detected the equipment will alarm; when bottles detected it will automatically resume production which is convenient for in-line production.

The mechanical structure of the whole machine adopts the reinforced rigid design which is simple and stable.

Features

- Suitable for labeling the surface of various round and square containers According to different models selected by customers one to three labels can be attached.

- Mechanical fixed-point labeling at any specified position of the container the positioning process is carried out in operation high efficiency good stability completely avoiding all the shortcomings of electronic positioning labeling.

- Camshaft and curved plate design prolong the service life of the machine and ensures the accuracy of labeling to the maximum extent.

- Non-damage bottle feeding mechanism all stainless steel bottle sorting star wheel and guiding plate mirror effect gloss eliminating the bottle body scratch caused by friction.

- Eight labeling station design in-and-out bottles are in a line.

- The device has only one independent central axis which is convenient for automatic lifting and lowering It does not need to be locked tightly and the adjustment is convenient. The position change of the pressure bottle turntable and the main shaft when the secondary locking is eliminated.

- The labeling station and the machine run synchronously that is the running speed of the main machine is automatically adjusted according to the bottle-feeding speed of the upstream machines and the accuracy of the label feeding is not affected.

- Open style bottle head pressing design that is the bottle can be manually removed at any station.

- Fully waterproof bottle holding structure can adapt to a variety of bottle types and a variety of labeling processes such as square bottles and strange shape bottles It does not need to replace the main parts and short product changeover time.

- The Labeling head enables 8-dimensional space adjustment tilt adjustment equipped with position display and accurate positioning adjustment Each adjustment structure is fully adjustable and requires no tools.

- The new type of clutch makes the tension more stable, and the operation is more stable. The three-point labeling head with easy height adjustment the adjustment smoother and the labeling board more stable.

- All parts are CNC machined with high precision to ensure the accuracy level of the equipment stable operation and low noise.

- Enclosed design to prevent dust.

- The equipment is designed for corrosion protection.

- Professional waterproof design ensures that all bearings operate in a dry environment.

- The equipment is equipped with material flow monitoring device and the running speed can be adjusted automatically.

- The whole machine is equipped with safety guard open the safety door and the machine will automatically stop.

- All electrical controls are manufactured according to the latest CE certification.

- Clean design for easy cleaning and cleaning.

- Stable operation speeds up to 13000 bottles / hour stepless speed regulation can be matched with the filling machine greatly improving the production efficiency of the whole line.

Technical Parameters

| Model: | IN-R6A3T |

| Labeling speed: | 4000-8000 BPH |

| Labeling precision: | ±1mm |

| Max label length: | 120mm (vertical direction) |

| Minimum bottle diameter: | 30m |

| Maximum bottle diameter: | 90mm |

| Minimum bottle height: | 120mm |

| Maximum bottle height: | 320mm |

| Paper coil inner diameter: | φ76mm |

| Paper coil outer diameter: | Φ400mm |

| Dimension: | 3000*2500*2070mm |

| Power: | 6 kW |

Components List

| Items | Supplier Origin |

| HMI | HTC Taiwan |

| PLC | Siemens Germany |

| Inverter | Danfoss Denmark |

| Servo system | YASKAWA Japan |

| Label detecting sensor | LION USA |

| Measuring fiber amplifier | Keyence Japan |

| Detection of electric eyes (reflective electric eye) | SICK Germany |

| Power | Meanwell Taiwan |

| Switches | Schneider France |

| Contactor & relays |

Batch/Date Coding Machine

Description

Designed for customers who print six to eight hours per day five days per week the Videojet 1220. Continuous

Inkjet printer provides up to 9000 hours of production before required preventive maintenance. The 1220 is specifically designed to meet basic coding and production applications across a wide range of substrates. It is ideal for single to multiple shift applications operating at moderate line speeds.

Features

Uptime Advantage

- Advanced core technology includes all ink system filters and common wear parts

- Intervals of up to 9000 hours between preventive maintenance

- Auto cleaning printhead for fast start-ups even after extended shutdowns

- Optional internal air pump eliminates need for external air minimizing potential for contaminants to enter the ink stream

Built-in productivity

- Ideal solution for a range of slow to moderate speed applications

- Print 1 to 5 lines of print for a range of coding needs

- Smart CartridgeTM fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

Code Assurance

- Multiple passwords protected access levels to system control menus help avoid unintentional input errors

- Storable print messages with pre- and calculated fields minimize required user input

Simple usability

- Bright display with WYSIWYG and function keys for easy operation

- Store up to 100 complex messages for easy recall – store even more messages using a standard USB memory stick

- User levels to separate operation from installation and maintenance

Technical Parameters

| Model: | Videojet 1220 |

| Line speed capability: | Can print 1 to 5 lines of print at speeds of up to 533 fpm (1625mpm)

(10 characters per inch single line of print) |

| Font matrix configuration: | Single line: 5×5 5×7 7×9 8×12 11×16 17×24 25×34

Twin-line: 5×5 5×7 7×9 8×12 11×16 Tri-line: 5×5 5×7 7×9 Quad-line: 5×5 5×7 Five-line: 5×5 |

| Linear bar codes: | UPC A&E; EAN 8 & 13; Code 128 A B & C.

UCC/EAN 128; Code 39; Code 93; Interleaved 2 of 5 |

| Data Matrix codes: | 10×10 12×12 14×14 16×16 18×18 20×20 24×24 34×34 |

| Nominal character height: | Selectable from 0079” (2mm) to 040” (10mm) depending on font |

| Throw distance: | Optimal: 0472” (12mm)

Range: 0197” (5mm) to 0591” (15mm) |

| Keyboard: | Membrane style with tactile feedback including 72 numeric alphabetic and special

function keys PC-style layout to approximate international PC convention |

| Display: | 320×240 Bright blue backlit 57” LCD display

WYSIWYG onscreen message editing |

| Custom logo/graphics: | Can be created by individual user on printer or PC with optional Videojet Logo Creator software |

| Character s: | American, Arabic, Bulgarian, Chinese, East European, European, Greek, Hebrew

Hungarian, Italian, Japanese, Japanese/Kanji, Japanese/Katakana, Korean, Russian, Simplified Chinese, Scandinavian, Thai, Traditional Chinese, Turkish, Vietnamese |

| Message storage: | 100 complex messages; unlimited storage using USB Standard USB with logo and memory backup features |

| Environmental protection: | IP55; stainless steel cabinet |

| Printhead: | Heated printhead

Diameter: 16” (413mm) Length: 95” (2410mm) |

| Printhead umbilical: | Ultra-flexible

Length: 656’ (2m) Diameter: 091” (23mm) Bend radius: 40” (1016mm) |

| Make-up fluid consumption: | As low as 24ml per hour |

| Fluids containers: | Ink Smart Cartridge™ 0793 qt (750ml)

Make-Up Smart Cartridge 0793 qt (750ml) |

| Temperature/humidity range: | 32°F to 122°F (0°C to 50°C)

0% to 90% RH non-condensing With selected inks, actual installation may require additional hardware based on production environment conditions |

| Electrical requirements: | Nominal supply power 100-120 / 200-240 VAC at 50/60 Hz 120 W |

| Approximate weight: | Unpacked and dry: 3968lbs (18kg) |

| Options: | Positive air pump

Dry air kit for high humidity (requires plant air) Products detect relay RS 485 expansion board RS232 encoder beacon expansion board 98-foot (3 m) umbilical 60- or 70-micron nozzle Food grade version 90-degree printhead Wide range of accessories |

| Manufacturer: | Videojet USA |

Cartoning system

Features

- Imported components electric and pneumatic parts

- Vertical cardboard mechanical adds cardboards whenever necessary without stopping the machine

- Manually adjust for different cartons within allowable range just takes 1~2 minutes

- Reasonable design vacuum cup sucks the cardboard fold and seal the bottom

- Small space occupation precision and durable parts provide the guarantee for stable running long life and high efficiency

- With protection device for cutter installation to avoid being hurt

- Easy operation machine can be used individually and combined with the packaging line

Technical Parameters

| Model: | INKX-18 |

| Carton size: | L200-400* W150-350*H100-350 |

| Capacity: | 18 p/h |

| Carton store capacity: | 100 pcs (1000mm) |

| Dimension: | 2400*2050*1450mm |

| Power supply: | 220V,50Hz |

| Air pressure: | 6 Kg/ cm2 |

| Air consumption: | 450NL/min |

| Size of the tape: | 48 60 75mm for option |

| Weight: | 550kg |

Automatic carton packing machine

Description

The machine is mainly composed of the following five parts

- Bottle feeding part

The multi-stage bottle feeding and pressure reducing mechanism is used to realize non-pressure bottle feeding. The passage for the feeding bottle can be adjusted on its width. In the same way the bottle separating plates can be adjusted as well with the enhancement of the cylinder achieving accurate positioning.

- Bottle grabbing mechanism

The device adopts a pneumatic gripper to clamp the bottle by compressed air and put it into the carton.

The solenoid valve controls the air and releases the bottle at which point the bottle is placed in the carton. Mainly realize slow gripping packing on accelerating speed precise positioning limit protection fault handling error indication.

- Carton guiding mechanism

The mechanism consists of a rising cylinder and a protective photoelectric sensor mainly to correct the carton on the chain of the carton and to guide the bottles on the gripper ensuring that the bottles can be placed into the carton smoothly.

- Carton feeding mechanism

It consists of a series of photoelectric sensors and conveying motors which are mainly used for automatic separating carton arrangement and automatic discharging of the carton.

- Safety equipment

There are protective safety doors in the front and rear parts of the machine safety switches are installed above the doors and various protectors are installed in the electric cabinets.

Through the combination of the above five parts of the mechanism the machine basically realizes the coordinated movement of each action.

Technical Parameters

| Model: | INZX-20K |

| Capacity: | cartons short edge into the box 4 boxes once and standard speed:

18cases/min |

| Packing layer: | One layer |

| Power supply: | 380V; 50Hz |

| Power: | 55 kW |

| Dimension: | 3340*1680*2800mm |

| Air pressure: | 6-8 bar |

| Air consumption: | 350 NL/min |

| Weight: | 2500 Kg |

Automatic carton sealing machine

Features

- Top to bottom Transmission belt the main transmission mechanism is high-precision and low noise make the belt life longer.

- The length of the folded sealing belts can be adjusted: 55mm 65mm 75mm.

- The machine has the alarm indicated system automatic stop system when the door opening this system keeps safe for maintenance.

Technical Parameters

| Model: | INFX-25 |

| Packing speed: | 18 cartons/min |

| Tape width: | 36~70mm |

| Max carton size: | L600*W500*H500mm |

| Minimum carton size: | L200* W150*H150mm |

| Power: | 400W |

| Size: | 1770*850*1500mm |

| Weight: | 250kg |

Components List

| Item | Brand Origin |

| PLC | Siemens Germany |

| HMI | Siemens Germany |

| VFD | Danfoss Denmark |

| Linear guide rail | IGUS Germany |

| Pneumatic components | AIRTAC Taiwan |

| Low voltage electric components | Schneider France |

| photoelectric sensor | Omoron Japan |

Belt conveyor & Buffering system

Description

The operation efficiency of the production line is mostly up to the configuration of the conveyor line. The configuration must consider the short-term shutdown of the rear-end equipment (for example replacement of labels etc.) ensuring the shutdown does not affect the operation of the front-end equipment and should be able to connect the front equipment and rear equipment well to make the whole the production line achieve high operation efficiency. Our production line’s layout fully considers the relationship between customer investment and production line efficiency. Based on the world’s advanced technology the above requirements can be well achieved. The mechanical structure is a new design most of the components are formed by stamping or bending which has the advantages of good rigidity light weight and good interchangeability. The transmission method features reliable operation and convenient maintenance which is suitable for conveying bottles with diameters of Ø40-Ø110mm .The electric control system adopts PLC (On the Rinsing-filling-capping tri-block) to control the operation of the whole container conveying buffer system and automatically conduct the functions of running speed acceleration and deceleration and automatic buffering.

Features

- The bottle belt is synchronously tracked with the host or the upstream and downstream equipment which are connected to control system

- The bottle does not fall does not jam and does not block during the conveying process

- According to the user’s needs the buffer platform can be in front of the labeling machine (the buffering time is usually about 1-2 minutes)

- When replenish PE label the filling process proceeds the filled bottles are stored on the buffer platform After finishing replenishing PE label the labeler starts labeling the line gets back to synchronizing production

- After replenishing the labeling machine produces at a higher speed to fill the platform with labeled bottles again and then resumes the synchronous production speed

- The conveyor belt structure is modular design the parts are interchangeable compact low noise easy to install and maintain and can be combined according to different capabilities and bottle types which has great flexibility.

- Electric control design is advanced and reasonable, and the control method can be designed according to the customer’s requirements and the required electrical control components can be selected to further improve the smoothness of transportation.

- The control switch position is reasonably according to the layout of the conveying system or the customer’s demand which is convenient for the user to operate.

Technical Parameters

| Motor power: | 037 kW / 6m |

| Width of the conveyor: | 110 mm |

| Height: | 1050 mm |

| Thickness of the steel plate: | 2 mm (SUS304) |

| Bottle volume: | 200-3000 ml |

| Bottle Diameter: | 50-100 mm |

Line 2 1500ml 2000ml

Bottle sorter

Features

- The main motor reducer uses a torque limiting mechanism to prevent damage to the machine in the event of a failure

- Adopt the bottle pushing and ejecting mechanism twice to ensure that there are bottles at each bottle dropping station and improve the efficiency of bottle discharging

- Adopt the bottle-hung mouth conveying air duct to prevent the bottle from tipping over during conveying

- A broken bottle rejection mechanism is provided

- It has a bottle jam detector which automatically stops and alarms when a bottle jam occurs

- A bottle presence/absence detector is provided to send a working signal to the elevator and the elevator will automatically replenish the bottle

- A photoelectric switch is installed on the bottle conveying duct to control the start and stop of the bottle unscrambler

- The bottle unscrambler is equipped with a grease nipple which can easily fill the gear bearing and Cam with lubricating oil

- Equipped with maintenance door and mold replacement door

- The main electrical components (inverter PLC photoelectric switch relay) use MITSUBISHI OMRON SIEMENS and other components

- The gas circuit system uses German FESTO products

Technical Parameters

| Model | IN-LP2600 |

| Bottle sorting heads: | / |

| Compressed air pressure: | 07Mpa |

| Air consumption: | 15M3/min |

| Bottle dimension: | Bottle diameter: 50-90 bottle height: 165-290 |

| Main motor power: | 22 kW |

| Lifting motor power: | 075 kW |

| Weight: | 3000Kg |

| Dimension: | D2360*H2060mm |

Components List

| Items | Supplier Origin |

| PLC | Siemens Germany |

| Touch screen | |

| Contactor | Siemens Germany |

| Thermal relay | |

| Switches | |

| Photoelectric electric sensor | Autonics SKorea |

| Pneumatic components | Airtac Taiwan |

Filling-capping Duo-block

Description

- Welded by SUS304 Product contact is SUS304 food grade;(SUS316 for option)

- High-efficiency rinsing-nozzles can spray water to any part inside the bottle.

- Corrosion-resistant bearings from NSK or SKF.

- Mechanical valve filling flow meter filling weighing filling or laser positioning filling as an option

- Open design for gear transmission.

- Bottle transporting system is neck-holding design.

- Equipped with VFD control more energy-saving.

- PLC control system is equipped.

- All electric components are supplied by the world-famous companies.

- French “ZALKIN” capping technology is used for higher performance.

- Capping torque can be adjusted accordingly.

- Cap absence can be detected and up-side down caps can be picked out.

- Online cap sterilizer as an option

Technical Parameters

| Model: | IN-GF40-8 |

| Capacity: | 7000 B/H (1500ml 2000ml) |

| Bottle height: | 120-310 mm |

| Bottle diameter: | 50-96 mm |

| Bottle mouth diameter: | 26-40 mm |

| Bottle type: | PET bottle |

| Cap type: | Flat cap / Sports cap |

| Filling heads: | 40 |

| Filling temperature: | ≤ 5℃ |

| Filling pressure: | 02-04 Mpa |

| Flow velocity of the valve: | 120-150 ml/s |

| Filling valve: | SUS316 |

| Product reservoir tank: | SUS304 |

| Capping heads: | 8 |

| Capping torque: | 06-28 Nm (adjustable) |

| Main motor power: | 22 kW AC 400V 50Hz IP55 |

| Installation power: | 4 kW |

| Power supply: | 415V 50HZ |

| Consumption of compressed air: | 08 m³/min (06MPa/H) |

| Consumption of aseptic water: | 35 m³/h (02-025Mpa) |

| Dimension: | 3800*2200*2200 mm |

| Weight: | 6500Kg |

Components List

| Items | Supplier Origin |

| PLC | Siemens Germany |

| Touch screen | |

| VFD | Siemens Germany |

| Contactor | Siemens Germany |

| Thermal relay | |

| Switches | |

| Micro relay | |

| Photoelectric electric sensor | Autonic SKorea |

| Pneumatic cylinder | Airtac Taiwan |

| Electromagnetic valve | |

| Air filter pressure reducing valve oil mister | |

| pressure adjusting valve | |

| Rinsing / Filling Pump | Grundfos Denmark |

Detailed description

Filling part

Features

- Non-contact filling

- Weighing filling technology

- Neck-holding design to ensure bottle mouth and the filling valve contact seamlessly

- Bottle-explosion-proof device installed the filling valve can turn off automatically

- The filler can adjust the height to match the different height bottles (have maximum and minimum height protection)

- Open style gear transmission highly efficient low noise long life-service easy maintenance

- The motor is adjusted by the inverter stepless frequency conversion speed regulation

- Bottle transporting system has simple structure short changeover time to fit different bottles Bottom-holding method for transporting

- PLC system-controlled errors can be displayed on the screen such as: bottle jammed cap absence

- No bottle no fill

- The liquid level inside the filling tank is monitored by the sensor ensuring stable filling

• The key electric parts are made by the world-famous companies - Sealing rings on the filler are manufactured in Europe

Capping Part

Features

- Caps will be unscrambled in the silo the amount is monitored

- Capping torque can be adjusted accordingly

- A flip-over adjuster installed on the slide to avoid up-side-down caps

- Two photoelectric sensors installed on the slide to alarm the cap-absence

- The capper can adjust the height to match the different height bottles (have maximum and minimum height protection)

E Cap hopper (for HDPE cap)

Features

- No damage on the plastic cap

- Transparent PC board for cap sorting

- Equipment with AC motor and speed reducer

- Indicator light for cap absence

- Upside-down caps will be picked out and sent back to the hopper

Technical Parameters

| Model: | IN-SGJ |

| Cap type: | Flat cap / sports cap |

| Material: | SUS 304 |

| Conveying capacity: | 20000 caps/h |

| Power: | 037 kW |

High-speed double-side adhesive labeling machine

A: The mainframe uses two of our cutting-edge technologies

- Label feeding with double pressure rollers which helps to improve labeling accuracy. Because the label is rolled by the active pressure roller before labeling it is helpful to eliminate label wrinkles improve labeling quality and use up the last label.

- Two-level swing lever spring-type label feeding clutch with additional belt brake to achieve high-speed constant tension label feeding.

B: Local performance explanation:

- As the machine uses several cutting-edge technologies and high-performance actuators-ultra-small inertia servo motors the system uses closed-loop control of the servo motor by a professional programmable controller from Siemens Germany using advanced and friendly human-machine. The interface system realizes man-machine dialogue. The host can achieve an accuracy level of 001 m / min during the control of the label feeding speed instead of 1 m / min of the general machine. In this aspect the machine has improved two accuracy levels. In terms of speed this machine uses a 750W Japanese Yaskawa high power ultra-small inertia servo motor and the speed of standard ting can be adjusted in a wide range of any number between 05-40 meters / minute to match the production speed of the customer’s production line. This achieves true high-speed labeling.

C: Performance comparison of IN-LD1000H linear improved single-side labeling machine with several other models:

- This labeling machine uses an ultra-small inertia servo motor while most labeling machines still use stepper motors.

- This labeling machine adopts PLC control instead of ordinary single chip microcomputer control.

- The human-machine interface of this labeling machine is a real digital control not a simple display function.

D: Conveying mechanism: imported AC motor inverter speed regulation

- Ultra-high-power AC motor coupled with large-capacity inverter speed regulation makes the bottle-feeding speed more stable which is helpful to improve the labeling accuracy. During the labeling process the position of the photoelectric switch of the measuring object can be adjusted which can achieve zero. Delay so this machine can achieve zero-pitch labeling which greatly improves the labeling speed. Most of the previous labeling machines used the photoelectric switch of the object to be stationary and used delay control that is when the photoelectric switch of the object sent a signal the system delayed output However if the system voltage changes or the load of the conveying mechanism changes during this process the labeling position of the label will be greatly deviated.

E: Labeling agency:

- Dimensional adjustment of the labeling head the labeling angle can be adjusted arbitrarily, and it is easy to paste various difficult transparent labels.

- For special-shaped products just by adjusting the angle lever you can quickly reach the angle you want fast operation and beautiful labeling effect.

- After the bottles enter the labeling machine’s conveyor line, they are separated into the sorting mechanism one by one by the bottle splitter and then the bottles are clamped by the belt and move forward synchronously. When the sensor detects the product, it is transmitted to Siemens PLC and then gives instructions to the photoelectric sensor to feed the label using an elastic scraper to scrape the label squeezing without a sponge roller and the powered sponge roller will press the label for the second time to ensure that no air bubbles are generated under the label.

- The mechanical structure of the whole machine adopts a strengthened rigid design which is simple and stable

Features

- Fast speed: 9000 bottles / H

- High accuracy: within ± 1mm (exclude the error between the bottle and the label)

- Fast bottle changing.

- Eight-dimensional adjustment of the header extremely convenient to adjust the desired angle

- The machine has strong stability, and it is easy and fast to adjust new products

- It is more suitable for double-sided labeling of shaped products without disassembling any parts

- Parts are made strictly according to food safety.

- High precision machining of parts.

- Each labeling head uses a control system for more stable labeling.

- Using a new type of main engine head (patent design) easy to adjust novel design and good stability

- Advanced control system program high accuracy of label stopping ensuring labeling accuracy.

- The main components are imported brands which increases the stability and durability of the machine

- Made strictly according to company requirements including materials

- Change bottles of different sizes just adjust the equipment

Technical Parameters

| Model: | IN-LD1000H |

| Labeling speed: | 9000 BPH |

| Labeling precision: | ±1mm |

| Label feeding speed: | 40000mm / min |

| Max label length: | 190mm (vertical direction) |

| Minimum bottle diameter: | 30m |

| Maximum bottle diameter: | 90mm |

| Minimum bottle height: | 120mm |

| Maximum bottle height: | 320mm |

| Paper coil inner diameter: | φ76mm |

| Paper coil outer diameter: | Φ400mm |

| Conveyor width: | 826mm |

| Dimension: | 3250*1500*1680mm |

| Power: | 3 kW |

Components List

| Items | Supplier Origin |

| HMI | HITECH Taiwan |

| Servo motor | YASKAWA Japan |

| Servo drive | YASKAWA Japan |

| VFD 750 | Danfoss Denmark |

| VFD 370 | Danfoss Denmark |

| PLC | Siemens Germany |

| Label photoelectric sensor | SICK Germany |

| Object photoelectric sensor | LUZUE Germany |

| Conveying motor750W | |

| Inverter motor | WANSHSIN Taiwan |

| Speed adjusting motor | Panasonic Japan |

| Thyristor speed regulator | Panasonic Japan |

| Switch | Panasonic Japan |

| Conveying chain 826mm | Meanwell Taiwan |

| Motor for the label supporting system | Rexnord USA |

| Power drive for the label supporting system | Panasonic Japan |

Date/Batch Coding

Features

- Speed without compromising quality

- Ideal solution for a range of slow to moderate speed applications:

- Single line maximum speed of 162 m/min (533 ft/min)

- Two-line maximum speed of 59 m/min (194 ft/min)

- Three-line maximum speed of 29 m/min (96 ft/min)

- Store up to 100 complex messages for easy recall Store even more messages using a standard USB memory stick

- Small and portable the 1220 is easily moved from line to line with minimal connections

- Engineered to keep your line running:

- Videojet’s advanced core technology includes all ink system filters and common wear parts

- Intervals of up to 9000 hours between preventative maintenance

- Auto cleaning printhead for fast start-ups even after extended shutdowns

- Optional internal air pump eliminates need for external air minimizing potential for contaminants to enter the ink stream

- No mess no waste fluid delivery:

- Advanced fluid management reduces makeup consumption to as low as 24 ml/hr.

- Smart CartridgeTM fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

- Simple Usability via Videojet standard CIJ interface:

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and maintenance

- Prompted user fields to help reduce errors

Technical Parameters

| Model: | VJ-1210 |

| Line speed capability: | Can print 1 to 3 lines of print at speeds of up to 533 ft/min (1625 m/min) (10 characters per inch single line of print) |

| Font Matrix Configuration: | 5×5 5×7 7×9 11×16 17×24 |

| Twin-line: | 5×5 5×7 7×9 |

| Tri-line: | 5×5 5×7 |

| Nominal Character Height: | Selectable from 0079’’ (2 mm) to 0279’’ (85 mm) depending on font 230 Kg |

| Throw Distance: | Optimal: 0472’’ (12 mm)

Range: 0197’’ (5 mm) to 0591” (15 mm) |

| Keyboard: | Membrane style with tactile feedback including 72 numeric alphabetic and special function keys PC-style layout to approximate international PC convention |

| Display: | 320×240 Bright blue backlit 57’’ LCD display WYSIWYG onscreen message editing |

| Custom Logo/Graphics: | Can be created by individual user on printer or PC with optional Videojet |

| Manufacturer: | Videojet USA |

Cartoning system

Features

- Imported components electric and pneumatic parts

- Vertical cardboard mechanical adds cardboards whenever necessary without stopping the machine

- Manually adjust for different cartons within allowable range just takes 1~2 minutes

- Reasonable design vacuum cup sucks the cardboard fold and seal the bottom

- Small space occupation precision and durable parts provide the guarantees for stable running long life and high efficiency

- With protection device for cutter installation to avoid being hurt

- Easy operation machine can be used individually and combined with the packaging line

Technical Parameters

| Model: | INKX-18 |

| Carton size: | L200-400* W150-350*H100-350 |

| Capacity: | 18 p/h |

| Carton store capacity: | 100 pcs (1000mm) |

| Dimension: | 2400*2050*1450mm |

| Power supply: | 220V,50Hz |

| Air pressure: | 6 Kg/ cm2 |

| Air consumption: | 450NL/min |

| Size of the tape: | 48 60 75mm for option |

| Weight: | 550kg |

Automatic carton packing machine

Description

The machine is mainly composed of the following five parts

- Bottle feeding part

The multi-stage bottle feeding and pressure reducing mechanism is used to realize non-pressure bottle feeding. The passage for the feeding bottle can be adjusted on its width. In the same way the bottle separating plates can be adjusted as well with the enhancement of the cylinder achieving accurate positioning.

- Bottle grabbing mechanism

The device adopts a pneumatic gripper to clamp the bottle by compressed air and put it into the carton.

The solenoid valve controls the air and releases the bottle at which point the bottle is placed in the carton. Mainly realize slow gripping packing on accelerating speed precise positioning limit protection fault handling error indication.

- Carton guiding mechanism

The mechanism consists of a rising cylinder and a protective photoelectric sensor mainly to correct the carton on the chain of the carton. And to guide the bottles on the gripper ensuring that the bottles can be placed into the carton smoothly.

- Carton feeding mechanism

It consists of a series of photoelectric sensors and conveying motors which are mainly used for automatic separating carton arrangement and automatic discharging of the carton.

- Safety equipment

There are protective safety doors in the front and rear parts of the machine safety switches are installed above the doors and various protectors are installed in the electric cabinets.

Through the combination of the above five parts of the mechanism the machine basically realizes the coordinated movement of each action.

Technical Parameters

| Model: | INZX-20K |

| Capacity: | cartons short edge into the box 4 boxes once and standard speed:

18cases/min |

| Packing layer: | One layer |

| Power supply: | 380V; 50Hz |

| Power: | 55 kW |

| Dimension: | 3340*1680*2800mm |

| Air pressure: | 6-8 bar |

| Air consumption: | 350 NL/min |

| Weight: | 2500 Kg |

Automatic carton sealing machine

Features

- Top to bottom Transmission belt the main transmission mechanism is high-precision and low noise make the belt life longer.

- The length of the folded sealing belts can be adjusted: 55mm 65mm 75mm.

- The machine has the alarm indicated system automatic stop system when the door opening this system keeps safe for maintenance.

Technical Parameters

| Model: | INFX-25 |

| Packing speed: | 18 cartons/min |

| Tape width: | 36~70mm |

| Max carton size: | L600*W500*H500mm |

| Minimum carton size: | L200* W150*H150mm |

| Power: | 400W |

| Size: | 1770*850*1500mm |

| Weight: | 250kg |

Components List

| Item | Brand Origin |

| PLC | Siemens Germany |

| HMI | Siemens Germany |

| VFD | Danfoss Denmark |

| Linear guide rail | IGUS Germany |

| Pneumatic components | AIRTAC Taiwan |

| Low voltage electric components | Schneider France |

| photoelectric sensor | Omoron Japan |

Belt conveyor & Buffering system

Description

The operation efficiency of the production line is mostly up to the configuration of the conveyor line .The configuration must consider the short-term shutdown of the rear-end equipment (for example replacement of labels etc.) ensuring the shutdown does not affect the operation of the front-end equipment and should be able to connect the front equipment and rear equipment well to make the whole the production line achieve high operation efficiency. Our production line’s layout fully considers the relationship between customer investment and production line efficiency. Based on the world’s advanced technology the above requirements can be well achieved. The mechanical structure is a new design most of the components are formed by stamping or bending which has the advantages of good rigidity light weight and good interchangeability. The transmission method features reliable operation and convenient maintenance which is suitable for conveying bottles with diameters of Ø40-Ø110mm.The electric control system adopts PLC (On the Rinsing-filling-capping tri-block) to control the operation of the whole container conveying buffer system and automatically conduct the functions of running speed acceleration and deceleration and automatic buffering.

Features

- The bottle belt is synchronously tracked with the host or the upstream and downstream equipment which are connected to control system.

- The bottle does not fall does not jam and does not block during the conveying process.

- According to the user’s needs the buffer platform can be in front of the labeling machine (the buffering time is usually about 1-2 minutes).

- When replenish PE label the filling process proceeds the filled bottles are stored on the buffer platform After finishing replenishing PE label the labeler starts labeling the line gets back to synchronizing production.

- After replenishing the labeling machine produces at a higher speed to fill the platform with labeled bottles again and then resumes the synchronous production speed.

- The conveyor belt structure is modular design the parts are interchangeable compact low noise easy to install and maintain and can be combined according to different capabilities and bottle types which has great flexibility.

- Electric control design is advanced and reasonable, and the control method can be designed according to the customer’s requirements and the required electrical control components can be selected to further improve the smoothness of transportation.

- The control switch position is reasonably according to the layout of the conveying system or the customer’s demand which is convenient for the user to operate.

Technical Parameters

| Motor power: | 037 kW / 6m |

| Width of the conveyor: | 110 mm |

| Height: | 1050 mm |

| Thickness of the steel plate: | 2 mm(SUS304) |

| Bottle volume: | 200-3000 ml |

| Bottle Diameter: | 50-100 mm |

Line 3 4000ml 5000ml

1 Filling-capping Dual-block

Description

- Welded by SUS304 Product contact is SUS304 food grade;(SUS316 for option)

- High-efficiency rinsing-nozzles can spray water to any part inside the bottle.

- Corrosion-resistant bearings from NSK or SKF.

- Mechanical valve filling flow meter filling weighing filling or laser positioning filling as an option

- Open design for gear transmission.

- Bottle transporting system is neck-holding design.

- Equipped with VFD control more energy-saving.

- PLC control system is equipped.

- All electric components are supplied by the world-famous companies.

- French “ZALKIN” capping technology is used for higher performance.

- Capping torque can be adjusted accordingly.

- Cap absence can be detected and up-side down caps can be picked out.

- Online cap sterilizer as an option

Technical Parameters

| Model: | IN-GF16-4 |

| Capacity: | 26000 B/H (500ml) |

| Bottle height: | 120-310 mm |

| Bottle diameter: | 50-96 mm |

| Bottle mouth diameter: | 26-40 mm |

| Bottle type: | PET bottle |

| Cap type: | Flat cap / Sports cap |

| Filling heads: | 16 |

| Filling temperature: | ≤ 5℃ |

| Filling pressure: | 02-04 Mpa |

| Flow velocity of the valve: | 120-150 ml/s |

| Filling valve: | SUS316 |

| Product reservoir tank: | SUS304 |

| Capping heads: | 4 |

| Capping torque: | 06-28 Nm (adjustable) |

| Main motor power: | 22 kW AC 400V 50Hz IP55 |

| Installation power: | 4 kW |

| Power supply: | 415V 50HZ |

| Consumption of compressed air: | 08 m³/min (06MPa/H) |

| Consumption of aseptic water: | 35 m³/h (02-025Mpa) |

| Dimension: | 2600*2200*2200 mm |

| Weight: | 5500Kg |

Components List

| Items | Supplier Origin |

| PLC | Siemens Germany |

| Touch screen | |

| VFD | Siemens Germany |

| Contactor | Siemens Germany |

| Thermal relay | |

| Switches | |

| Micro relay | |

| Photoelectric electric sensor | Autonic SKorea |

| Pneumatic cylinder | Airtac Taiwan |

| Electromagnetic valve | |

| Air filter pressure reducing valve oil mister | |

| pressure adjusting valve | |

| Rinsing / Filling Pump | Grundfos Denmark |

Detailed description

Filling part

Features

- Non-contact filling

- Weighing filling technology

- Neck-holding design to ensure bottle mouth and the filling valve contact seamlessly

- Bottle-explosion-proof device installed the filling valve can turn off automatically

- The filler can adjust the height to match the different-height bottles(have maximum and minimum height protection)

- Open style gear transmission highly efficient low noise long life-service easy maintenance

- The motor is adjusted by the inverter stepless frequency conversion speed regulation

- Bottle transporting system has simple structure short changeover time to fit different bottles Bottom-holding method for transporting

- PLC system-controlled errors can be displayed on the screen such as: bottle jammed cap absence

- No bottle no fill

- The liquid level inside the filling tank is monitored by the sensor ensuring stable filling

• The key electric parts are made by the world-famous companies - Sealing rings on the filler are manufactured in Europe

Capping Part

Features

- Caps will be unscrambled in the silo the amount is monitored

- Capping torque can be adjusted accordingly

- A flip-over adjuster installed on the slide to avoid up-side-down caps

- Two photoelectric sensors installed on the slide to alarm the cap-absence

- The capper can adjust the height to match the different-height bottles(have maximum and minimum height protection)

C Cap hopper (for HDPE cap)

Features:

- No damage on the plastic cap

- Transparent PC board for cap sorting

- Equipment with AC motor and speed reducer

- Indicator light for cap absence

- Upside-down caps will be picked out and sent back to the hopper

Technical Parameters

| Model: | IN-SGJ |

| Cap type: | Flat cap / sports cap |

| Material: | SUS 304 |

| Conveying capacity: | 20000 caps/h |

| Power: | 037 kW |

Adhesive labeler

Introduction

This machine is suitable for side labeling especially on the cylindrical flat square rectangular and elliptical bottles The machine is economical and easy to operate. The performance is stable with a level off . The system easy changeover based the requirement.

Features

- Labeling speed up to 5000bph( according to the length of label )

- PLC Control System which is easy to control

- Simple Straight Forward Operator Controls

- On-Screen trouble description which is easy to solve

- Stainless Frame

- Open Frame design easy to adjust and change the label

- Variable Speed with stepless motor

- Label Count Down (for precise run of number of labels) to Auto Shut Off

- Stamping Coding Device attached

Technical Parameters

| Model: | IN-L100A |

| Label size: | Diameter 30-125 mm |

| Bottle diameter: | 28-125 mm |

| Sleeve label length: | 30-250 mm |

| Thickness: | 0035mm |

| Label material: | PVC/PET |

| Dimension: | 2440*890*2200 mm |

| Weight: | 750 Kg |

Components List

| Items | Supplier Origin |

| PLC | Siemens Germany |

| HMI | |

| VFD | Panasonic Japan |

| Contactor | Schneider France |

| Thermal relay | |

| Switches | |

| Photoelectric sensor | Panasonic Japan |

| Motor | TWT Taiwan |

| Stepping motor | Panasonic Japan |

| Stepping drive | Panasonic Japan |

Date/Batch Coding Machine

Features

- Speed without compromising quality

- Ideal solution for a range of slow to moderate speed applications

- Single line maximum speed of 162 m/min (533 ft/min)

- Two-line maximum speed of 59 m/min (194 ft/min)

- Three-line maximum speed of 29 m/min (96 ft/min)

- Store up to 100 complex messages for easy recall Store even more messages using a standard USB memory stick

- Small and portable the 1220 is easily moved from line to line with minimal connections

- Engineered to keep your line running

- Videojet’s advanced core technology includes all ink system filters and common wear parts

- Intervals of up to 9000 hours between preventative maintenance

- Auto cleaning printhead for fast start-ups even after extended shutdowns

- Optional internal air pump eliminates need for external air minimizing potential for contaminants to enter the ink stream

- No mess no waste fluid delivery:

- Advanced fluid management reduces makeup consumption to as low as 24 ml/hr

- Smart CartridgeTM fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

- Simple Usability via Videojet standard CIJ interface:

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and maintenance

- Prompted user fields to help reduce errors

Technical Parameters

| Model: | VJ-1210 |

| Line speed capability: | Can print 1 to 3 lines of print at speeds of up to 533 ft/min (1625 m/min) (10 characters per inch single line of print) |

| Font Matrix Configuration: | 5×5 5×7 7×9 11×16 17×24 |

| Twin-line: | 5×5 5×7 7×9 |

| Tri-line: | 5×5 5×7 |

| Nominal Character Height: | Selectable from 0079’’ (2 mm) to 0279’’ (85 mm) depending on font 230 Kg |

| Throw Distance: | Optimal: 0472’’ (12 mm)

Range: 0197’’ (5 mm) to 0591” (15 mm) |

| Keyboard: | Membrane style with tactile feedback including 72 numeric alphabetic and special function keys PC-style layout to approximate international PC convention |

| Display: | 320×240 Bright blue backlit 57’’ LCD display WYSIWYG onscreen message editing |

| Custom Logo/Graphics: | Can be created by individual user on printer or PC with optional Videojet |

| Manufacturer: | Videojet USA |

Carton case sealer

Features

- Top to bottom Transmission belt the main transmission mechanism is high-precision and low noise make the belt life longer

- The length of the folded sealing belts can be adjusted: 55mm 65mm 75mm

- The machine has the alarm indicated system automatic stop system when the door opening this system keeps safe for maintenance

Technical Parameters

| Model: | INFX-25 |

| Packing speed: | 18 cartons/min |

| Tape width: | 36~70mm |

| Max carton size: | L600*W500*H500mm |

| Minimum carton size: | L200* W150*H150mm |

| Power: | 400W |

| Size: | 1770*850*1500mm |

| Weight: | 250kg |

Components List

| Item | Brand Origin |

| PLC | Siemens Germany |

| HMI | Siemens Germany |

| VFD | Danfoss Denmark |

| Linear guide rail | IGUS Germany |

| Pneumatic components | AIRTAC Taiwan |

| Low voltage electric components | Schneider France |

| photoelectric sensor | Omoron Japan |

Belt conveyor & Buffering system

Description

The operation efficiency of the production line is mostly up to the configuration of the conveyor line. The configuration must consider the short-term shutdown of the rear-end equipment (for example replacement of labels etc.) ensuring the shutdown does not affect the operation of the front-end equipment and should be able to connect the front equipment and rear equipment well to make the whole the production line achieve high operation efficiency. Our production line’s layout fully considers the relationship between customer investment and production line efficiency. Based on the world’s advanced technology the above requirements can be well achieved. The mechanical structure is a new design most of the components are formed by stamping or bending which has the advantages of good rigidity light weight and good interchangeability. The transmission method features reliable operation and convenient maintenance which is suitable for conveying bottles with diameters of Ø40-Ø110mm . The electric control system adopts PLC (On the Rinsing-filling-capping tri-block) to control the operation of the whole container conveying buffer system and automatically conduct the functions of running speed acceleration and deceleration and automatic buffering.

Features

- The bottle belt is synchronously tracked with the host or the upstream and downstream equipment which are connected to control system

- The bottle does not fall does not jam and does not block during the conveying process

- According to the user’s needs the buffer platform can be in front of the labeling machine (the buffering time is usually about 1-2 minutes)

- When replenish PE label the filling process proceeds the filled bottles are stored on the buffer platform After finishing replenishing PE label the labeler starts labeling the line gets back to synchronizing production

- After replenishing the labeling machine produces at a higher speed to fill the platform with labeled bottles again and then resumes the synchronous production speed

- The conveyor belt structure is modular design the parts are interchangeable compact low noise easy to install and maintain and can be combined according to different capabilities and bottle types which has great flexibility

- Electric control design is advanced and reasonable, and the control method can be designed according to the customer’s requirements and the required electrical control components can be selected to further improve the smoothness of transportation

- The control switch position is reasonably according to the layout of the conveying system or the customer’s demand which is convenient for the user to operate

Technical Parameters

| Motor power: | 037 kW / 6m |

| Width of the conveyor: | 110 mm |

| Height: | 1050 mm |

| Thickness of the steel plate: | 2 mm(SUS304) |

| Bottle volume: | 200-3000 ml |

| Bottle Diameter: | 50-100 mm |

Line 4: 20L barrel

Bottler filler

Features

- This weighing filling machine is for filling 20kg to 30kg liquid. Each filling head has the weight and feedback system each filling head can be regulated.

- This type of filler adopts PLC to control touch screen control panel. It applies dive method to fill, and it reduces foam.

- The whole machine meets GMP standard it is easy to clean and maintain and the parts which contact with the filling material are made of high-quality stainless steel.

- The whole machine is safe eco-friendly and sanitary It adapts to various kinds of working places.

Performance advantages

- Control system—- Mitsubishi PLC control system.

- Operation interface—-Two rows of the color operation interface Convenient operation stable and reliable.

- Function improvement—-The feeding nozzle is equipped with filling blocker. This machine can realize diving filling according to the material properties(this function can be selected.

- Filling show—the filling result is displayed in the unit of weight intuitive and clean.

- Real-time alarm—-Automatic alarming when the fault happens automatic stopping and alarming when the system appears serious breakdown.

- Electrical elements—-Adopting international famous brand to ensure the remarkable quality stability and high precision.

- Machine elements—-The parts contacted with the material use the 316 high-quality stainless steel and non-poisonous anti-corrosive PTEF hose. Other machine parts use the 304 high-class stainless steel.

- Expansion function—– We can carry out special configuration according to the customers’ .requirements(material airtight heating and sterilizing etc.)

- Counting detection—-Real- time counting reflecting the output directly.

- Filling detection—-No-bottle no-filling it will not conduct filling if the bottles are not enough.

- Function upgrading—We have designed intelligent weighing feedback system to realize the unmanned offloading function.

- Environmental protection configuration—-Equipped with eco-friendly frame realizing more clean and sanitary operation environment(this environmental protection configuration can be selected).

- Interval filling—Minimum filling volume can reach 40ml We can realize interval filling(this function can be selected according to the customers’ requirements).

- Maintenance condition—-Fully accords to the GMP requirements easy to disassemble and clean.

- Function upgrading—We have designed intelligent weighing feedback system to realize the unmanned offloading function Filling dose is more accurate the original ± 1% of filling accuracy increased about 10 times.

- Changing specification–According to the changing of market specifications 5L 20L large-dose packaging range only in the same machine operation. To save the equipment cost for the customer when changing filling specifications just adjust no need to change any components easily done.

Technical Parameters

| Model: | IN-LF8 |

| Filling heads: | 8 filling heads |

| Output: | 650 BPH |

| Bottle size range: | L: 160mm~360mm W:140mm~260mm H: 250mm~500mm |

| Diameter of bottle mouth: | ≥Φ40mm |

| Power Supply: | 220 V 50 Hz |

| Power: | 2kW |

| Size: | 2070*850*1500mm |

| Weight: | 1550kg |

Components List

| Item | Brand Origin |

| PLC | Siemens Germany |

| HMI | Siemens Germany |

| VFD | Danfoss Denmark |

| Linear guide rail | IGUS Germany |

| Pneumatic components | AIRTAC Taiwan |

| Low voltage electric components | Schneider France |

| photoelectric sensor | Omoron Japan |

Capping machine

Technical Parameters

| Model: | IN-YGJ |

| Capacity | 2000BPH |

| Cap’s Diameter | ≤ Ø70mm |

| Power | 2KW |

| Voltage | 220V 50HZ |

| Weight | 550KG |