Description

Toilet Paper Line

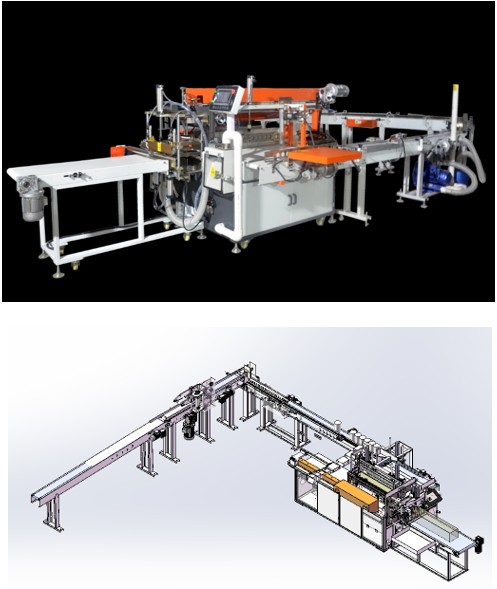

FULLY AUTOMATIC REWINDING & PACKAGING COMBINATION PRODUCTION LINE

The LMP450-automatic rewinding machine combination production line represents a pinnacle in control technology for rewinding production lines. It seamlessly connects the automatic drilling rewinding machines, automatic paper cutting machines, and paper packaging machines via a sophisticated transmission system, enabling a well-organized and highly efficient fully automated production process. This setup is a discerning choice for the majority of businesses involved in the production of sanitary paper products.

Raw paper width: 3000mm

Daily output is expected to be 7-8 tons / 8 hours

Based on paper gram weight: 13.5g/m² -22g / m²

Machine list

- IND-5000 fully automatic rewinding machine

- Conveying

- Automatic paper cutter (Fully automatic paper rolling band saw paper cutter)

- Packing machine

Technical parameter

| NO. | Project | Technical parameter |

| Host part | ||

| 1 | Host structure | Wall plate type |

| 2 | The maximum width of the original paper | 2880mm |

| 3 | Quantitative original paper | 13-22g / m2 (single layer) |

| 4 | number of plies | 1-3 layer |

| 5 | Design speed | 500m/min |

| 6 | Re-volume diameter | ¢40mm-¢135mm |

| 7 | Re-volume diameter control | manual regulation |

| 8 | Re-volume length | Control the number of sections through the touch screen |

| 9 | Re-roll speed adjustment | Set the adjustment independently through the touch screen |

| 10 | External diameter of finished paper pipe | ¢32mm—¢50mm |

| 11 | Can produce no core roll paper | ability |

| 12 | No-core coil device control | PLC + pneumatic control |

| 13 | Core-free volume paper | 2880mm (replace less reel but recommended not recommended to be less than 2800) |

| 14 | Perforating device | A spiral punch knife roller, 4 pieces of punch face knife

A punching knife roller Automatic induction knife shaft protection system |

| 15 | The hole node distance | Standard pitch: 110mm (please specify otherwise, adjust the pitch by replacing the sprocket) |

| 16 | Error in spacing between holes | ±2mm |

| 17 | Punch line ratio | 3mm:1mm |

| 18 | Adjust the hole unit angle | hand movement |

| 19 | Pressure edge grain device | Install on host |

| 20 | Pressure mode of edge lines | Use the integral air bag for pressure |

| 21 | Pressure edge grain wheel | Conventional embossing: the edge line width is 4.8mm, and the line point shape is square point |

| 22 | Number of embossing wheels | 29 sets, 58 embossed lines, 32mm apart (i. e. the distance between the embossed center line and the finished paper roll is 16mm) |

| 23 | motive power | 7.5 kW trim motor 0.2 kW; |

| The paper back frame part | ||

| 30 | Paper back frame structure | Wall slab type (30mm thick) |

| 31 | Paper width of paper rack | 2850mm |

| 32 | Back paper roll diameter | ≤¢1500mm |

| 33 | Raw paper roll paper core inner diameter | ¢76mm |

| 34 | Roll back the belt | Two pieces / group |

| 35 | Roll-back speed adjustment | Independent speed adjustment by each rear frame of the reducer |

| 36 | Left and right position adjustment of base paper adjustment | Handwheel adjustment |

| 37 | Paper way | Apply paper arm pneumatically on paper |

| Operation control system | ||

| 40 | operation interface | Human-machine operation interface (touch screen) |

| 41 | Operate the box position | Install on host |

| 42 | Main motor speed control | Frequency conversion control |

| Other parameters | ||

| 43 | Minimum pressure requirement | 0.4Mpa |

| 44 | Gas consumption | 1000L/H |

| 45 | Lead paper method | hand movement |

FULLY AUTOMATIC PAPER ROLLING BAND SAW PAPER CUTTER

Main technical parameters:

Model: LM4200 LM5500 / customized

Blade: 3750 * 60 * 0.6

Grindstone: diamond grinding wheel

Cutting speed: 300 cut / minute

Power supply voltage: 380V, 50Hz

Air source pressure: 0.6 MPA (customer provided)

Total power: 7.5KW

Cutting size: 50-210MM length, 40-135MM diameter

Performance and features:

◆ Employing an LCD touch screen interface to make the system user-friendly, simplifying calculations and adjustments, facilitating easy setup, and promoting seamless human-machine interaction.

◆ Equipped with an automatic knife sharpening system and screen-controlled paper feed, ensuring the paper cutting process is exceptionally safe without requiring manual intervention. This substantial safety enhancement significantly reduces past instances of accidents, thereby increasing operator confidence in the system.

◆ This model is suitable for both deliberate and accidental paper cutting scenarios.

◆ To adapt to different specifications, users can effortlessly configure the required cut quantity and length via the touch screen, with the flexibility to adjust the head and tail material dimensions as needed.

◆ The entire machine boasts advanced settings, stable performance, and utilizes a unified range of electrical components for control. It incorporates PLC program control, frequency converter speed regulation, and servo motor drive, ensuring durability and reliability.

MULTIPLE ROWS PACKING MACHINE

Performance and features:

Packaging solution for sealing 3 to 6 rows of commercial paper bags. It seamlessly integrates with a paper cutting machine to automate material handling, bagging, sealing, cutting, and waste disposal.

PLC computer programming, featuring an LCD text display for parameter adjustments. This setup allows for precise parameter configuration, enabling efficient human-machine interaction.

With just one operator, this machine replaces traditional manual material handling, resulting in reduced manufacturing and management costs for businesses.

It incorporates an initial induction mechanism to enhance worker safety, providing a more secure operating environment.

Main technical parameters

| Gas source air pressure: | 0.6Mpa |

| supply voltage: | 380V, 50HZ |

| Packing speed: | 4-6 lift / minute |

| packing measurement: | L 300-900,W 180-400,H 100-180 |

| aggregate capacity: | 8.5KW |

| outline dimension: | L 5770mm×W 5150mm×H1500mm |