Description

View our catalogue below or (click to download).

GENERAL DESCRIPTION

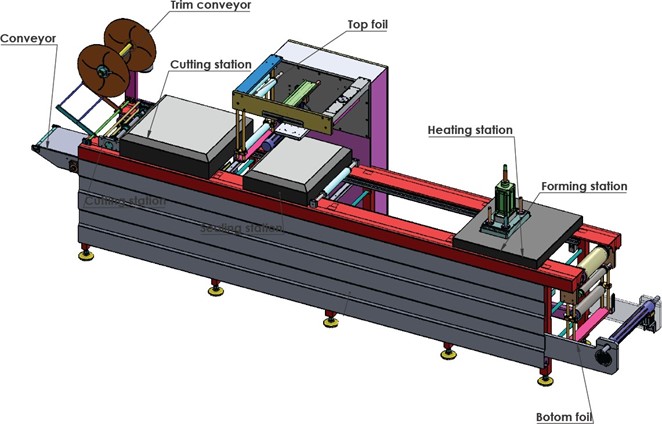

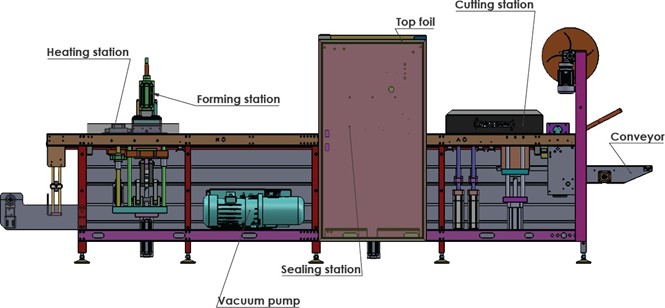

| Machine Type | MVZ–150 The Automatic Thermoform Packaging Machine |

|

Purpose of Application |

The automatic thermoform packaging machine MVZ-150 was conceived for large productions; it can be integrated in complete lines so it expresses its potentialities also in the interaction with other elements (automatic dosing system, multihead, systems of automatic loading). It meets the production needs of a large company with high automation level. Preheating plates, forming mould, filling station, vacuum unit gas injection station, sealing and cutting station are the main units of the machine. Transportation of the packing film is carried out by an extra strong regina-griping chain. You can obtain packages in plastic material both flexible and rigid, therefore linear and perimetric cuts (shaped). User applications; forming, Sealing, Vacuum , Cutting The MVZ –150 offers you a more comfortable working environment with a servo motor for digital advancement, a state-of the art PLC control system which allows for monitoring of parameters and necessary adjustments to be made easily and a large touch screen operator panel. |

| Application Areas | Meat, Cheese Varieties, Olive, Ready Meals, Chicken, Sea Food, Dairy Deserts, Cake, Bread, Salami, Dry Fruit, Fresh Noodles, Medical Products |

CONSTRUCTION FEATURES AND DIMENSIONS

- Made in stainless steel (AISI 304 quality) to endure the hardest production environments and the most intense stresses.

- It can be integrated in complete lines so it expresses its potentialities also in the interaction with other

- Designed to endure intense washing cycles and frequent sanitations and hygienic requirements. All production environments and all sanitation

- Designed ergonomically guaranteeing wide range for the management of the format and mould changes as well as the maintenance.

- Freely variable distance between moulds, giving a possibility to use dies with different cut-off

- Easy access to any system or mechanism, with easy open side

- Corrosion-resistant gripper

- Moving elements of the machine are connected with bearings.

| Machine length approx. | 4.000 mm |

| Machine width approx. | 1.300 mm |

| Machine height approx. | 2.000 mm |

| Machine weight approx. | 2.000 Kg |

Forming Station

- Forming with compressed

- Replaceable forming frames, for format….

- Set of forming plates for soft film, for format….

- Set of plates for changing the forming depth.

Loading Area

- Length of the loading area: approx. 1500~2500 mm, modifiable according to user’s needs

- Standard system to support packages including support bars, for format …. That prevents

filled packages to hang down.

Vacuum

- Evacuation and gas flushing through special openings in the lower section of vacuum and sealing

- Vacuum from company for both machines “DVP (ITALY)’’, 150 m3/h/

Sealing Station

- Changeable sealing frames with sealing gasket, ….

- Lifting system of sealing and forming moulds pneumatic

Cutting and Discharge Area

- Standard system to support packages including support bars, for formats ….

- Discharge of packages: 500-1000 mm conveyor;

- Film trim and edge removal: with edge trim rewind;

- Pneumatic cross cutting unit for flexible film

Connection Parameters

| Necessary electric current | 380 V, 3 phase, 50 HMVZ (modifiable according to user’s needs) |

| Electric Consumption | About 14.5 Kw – 380 V |

| Necessary compressed air (Customer has to supply) | 1500 liters/min., work pressure 6-8 atm

Compressed air supply with pressure regulator and air conditioning unit |

| Necessary water supply for cooling

(Customer has to supply) |

200–300 liters/hour, temperature: 10–14 °С, 6000 KCAL/hour, 1,5–3 atm |

Film Unwind

- Lower and upper films unwind reel core diameter 3″ (75 mm),

- Lower and upper films unwind reel maximum diameter 500 mm,

- Lower and upper films with reel mandrel and pneumatically actuated tension control

- Tensioning system for pre-unwinding of the plastic film with dedicated pneumatic

- End of film sensors for lower and upper films

- Regardless of the weight of the package and changes of the machine speed, lower film shift using servo drive ensures precise maintenance of the stroke

- Mechanical device for winding and removing waste film

Control system

- Electrical components from company ‘‘TELEMEKANIQUE (FRENCH) or SCHNEIDER (GERMAN)’’

- PLC from company ‘‘OMRON (JAPAN)’’

- Information input, control and management with liquid crystal touch colour screen

- PLC control system which allows for monitoring of parameters and necessary adjustments to be made easily and a touch screen operator panel with protection against external

- It is possible to control separate parts of the machine by entering password;

- During the working cycle the interface gives information about actuation of mechanisms and valves;

- Counters of working hours and work cycles;

- Regulation of temperature through interface;

- Built-in temperature control loops

Safety system

- Security censors from company ‘‘PILMVZ (GERMAN)’’

- Protection frame in loading area and around cutting tools

- Security censors that forbids machine working without frame

- If the safety guards are lifted or moved; Security censors stops the movement of the machine

- If there is a foreign body (for example, arm) between top and lower of the dies; Security censors that stops the movement of the machine

- EMERGENCY STOP

Pneumatic system

- Pneumatics from company ‘‘SMC(JAPAN) or FESTO (GERMAN)

- Noise Cancelling System

- Valve system for forming and sealing stations;

- Safety valve for air pressure connection

- Compressed air supply with pressure regulator and air conditioning unit

- Filter of fine cleaning of compressed air from oils for moulding.

Origins of the equipment

| Vacuum Pump | DVP (ITALY) |

| Pneumatics | SMC(JAPAN) or FESTO (GERMAN) |

| Electricity | TELEMEKANIQUE (FRENCH) or SCHNEIDER (GERMAN) |

| Operator | OMRON (JAPAN) |

| PLC | OMRON (JAPAN) |

| Pulling | OMRON (JAPAN) |

| Prok switches | OMRON (JAPAN) or SICK (GERMAN) |

| Electric Terminals | WEIDMÜLLER (GERMAN) |

| Cable guides | WÜRTH (GERMAN) |

| Power supply | OMRON (JAPAN) |

| Inverter | OMRON (JAPAN) |

| Chain drive | REGINA (ITALY) OR IWIS (GERMAN) |

| Reductor and engines | VARVEL (ITALY) |

SPECIFICATIONS FOR THE CUSTOMER DEMAND

| Product | Processed chicken |

| Capacity | 6-8 cycles/min. |

| Mould Properties | Made by complete aluminium |

|

Packing Dimensions |

Weight of packed products: based on the customer demands

Internal dimensions (indicative): as indicated in the foil flow diagrams External dimensions (approximate): as indicated in the foil flow diagrams Forming depth, depth of extraction: up to 100 mm |

|

Bottom Film |

1) Mold: Soft PA+PE Width: 422 mm Thickness:for up to 150~200 μ

2) Mold: Soft PA+PE Width: 420 mm Thickness:for up to 150~200 μ 3) Mold Rigid APET+PE Width: 422 mm Thickness:for up to 350~600 μ |

|

Upper Film |

Thermoformable, Flexible, PA+PE Thickness: up to 70~100 μ

Width of the Upper Film: 410 mm |

| Types of Packaging | Forming, Vacuum, Sealing, Cutting |