Description

ICE CREAM PRODUCTION EQUIPMENT

SCOPE OF OFFER: –

1000L/H – Dairy ice-cream production line / 500ml, 2 litre and 5 litre tubs.

Quotation: 1000L/H Dairy Ice Cream Production Line – Filling into tubs, 500ml, 2L, 5L

| MACHINE DESCRIPTION | MODEL | QTY | UNIT PRICE | PRICE | |

| 1) Water Supply Equipment | |||||

| 1.1) Electrical control system |

380V/220V |

1set | |||

| 1.2) Water storage tank |

2000L |

1set | |||

| 1.3) Constant temperature tank |

1T/H |

1set | |||

| 1.4) Water pump |

3T/24M |

1set | |||

| SUB TOTAL | |||||

| 2) Milk Receiving Equipment | |||||

| 2.1) Milk weight tank |

500L |

1set | |||

| 2.2) Electronic scale |

1T |

1set | |||

| 2.3) Duplex filters |

100 |

1set | |||

| 2.4) Milk storage tank |

3000L |

2set | |||

| 2.5) Centrifugal pump |

3T/H |

3set | |||

| 2.6) Self-priming pump |

10T/H |

1set | |||

| SUB TOTAL | |||||

| 3) Preparation Equipment | |||||

| 3.1) High-speed emulsification tank |

500L |

1set | |||

| 3.2) Water-powder mixer |

3T/H |

1set | |||

| 3.3) Mixing tank |

500L |

2set | |||

| 3.4) Duplex filters |

100 |

1set | |||

| 3.5) Plate pasteurizer |

1T/H |

1set | |||

| 3.6) High pressure homogenizer |

1T/25MPa |

1set | |||

| 3.7) Aging tank |

1000L |

2set | |||

| 3.8) Centrifugal pump |

3T/24M |

2set | |||

| 3.9) CIP return pump |

10T/24M |

2set | |||

| 3.10) Freezing Machine |

300Type |

2set | |||

| 3.11) Rotor pump |

1000L/H |

2set | |||

| SUB TOTAL | |||||

| 4) Filling Machine | |||||

| 4) Filling machine |

|

1set | |||

| SUB TOTAL | |||||

| Installation, commissioning and training (excluding pipe work) | |||||

| TOTAL: | |||||

WATER SUPPLY EQUIPMENT

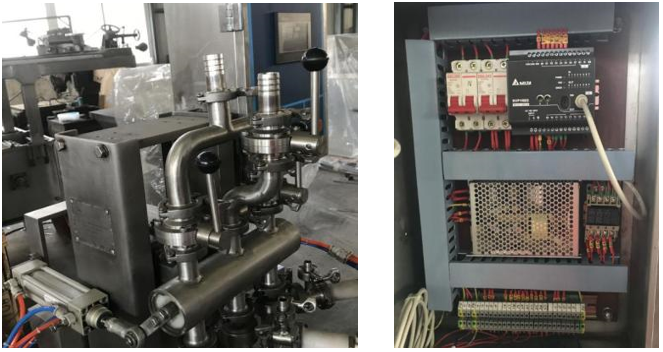

1.1 Constant pressure system

For high efficiency and energy saving / Water supply pressure stable

For high efficiency and energy saving / Water supply pressure stable

According to the demand of water pressure, adjust the speed of the pump and motor pump flow and variable flow numbers, variable pressure or change in the flow of constant pressure water supply. High efficiency and energy saving equipment running in the best condition, to achieve a high energy-saving.

Closed loop control system, can adjust the set pressure and system pressure feedback.

SUS304 material, ABB motor power: 4Kw, stainless steel casings, head of the 24 m

1.2 Water Storage Tank (can be plastic HPDE)

Structure

Structure

- Single layer structure

- Material of tank is stainless steel

- Normal volume:2000L,diameter:1340mm,height:2760mm

Description

- Quick open manhole

- Numeral indication type thermometer

- T type cleaning head

- Hauling lever style releasing valve

- Adjustable taper branch feet.

- Digital thermometer manhole, T cleaning head, the material valve lever type, adjustable tapered foot in and out, move the caliber of: 51 mm

1.3 Constant temperature water cooling tank

Description

Description

- Quick open manhole.

- Insect flies’ sanitary ventilation hood.

- Adjustable triangular legs.

- Removable feed management suite.

- Digital thermometer

- Paddle

- Gauge [glass].

Structure

- Double layer SS structure

- Material of tank 304 stainless steel

- Normal volume:1000L,

1.4 Water Pump

SUS304 material,

SUS304 material,

ABB motor power: 1.1 Kw,

Stainless steel casings,

Flow3T/H

Head of the 24 m

MILK RECEIVING EQUIPMENT

2.1 Milk weight tank – 500L

Description:

All this equipment is made of SUS304 plate, polished inner surface and outer scaly pattern throw horizontal rectangular groove, above the two open lid with stainless steel wire mesh and filtration equipment is made, the other one into the discharge port can be connected with the pipeline, intermittent use, a gate valve with a plug-in milk for the switch, after weighing just rotate the handle 90 degrees, you can discharge, effort, good sealing performance, no leakage of material.

All this equipment is made of SUS304 plate, polished inner surface and outer scaly pattern throw horizontal rectangular groove, above the two open lid with stainless steel wire mesh and filtration equipment is made, the other one into the discharge port can be connected with the pipeline, intermittent use, a gate valve with a plug-in milk for the switch, after weighing just rotate the handle 90 degrees, you can discharge, effort, good sealing performance, no leakage of material.

Technical parameter:

- Equipment is used for milk receiving temporary and weighing

- Material for health level SUS304 material

- Equipment external dimensions: L × W × H = 1 200×600×800mm

2.2 Electronic scale

Technical parameter:

Technical parameter:

Maximum weighing: 1000Kg

Minimum scale: 50g / 500g

Specifications Size: 1000 * 1000mm

SUS304

2.3 Duplex filters

SUS304 material, smooth wall, no dead ends. Optional alternate use.

SUS304 material, 120 mesh.

2.4 Milk Storage tank 3000L

Description

Description

- Quick open manhole.

- The spherical CIP

- Insect sanitary ventilation hood.

- Adjustable triangular legs.

- Removable feed management suite.

- Digital thermometer.

- configured according to customer requirements [ladder].

- paddle

- gauge [glass].

- The anti-vortex plate.

- Miller board jacket, through the ice for cooling, hot water heating.

Technical parameter

- 1, SUS304 material, the outer diameter of the tank φ1640mm, can height 3050mm,

- 2, Polyurethane insulation, φ400 manhole, φ76 dust respirators, φ51 material inlet and outlet,

- 3, The heat transfer area:8 ㎡,

- 4, Temperature display instrumentation, level indicator, stirring speed 43rpm.

- 5, Volume: 3000L.

2.5 Centrifugal pump

- Production capacity: 3T/H

- Motor total power:1.1KW

- SUS304 material

2.6 Self priming pump

- Production capacity:10T/24M

- Motor total power:3KW

3.1 High-speed emulsification tank

Description

Description

- Effective volume: 500L

- Size:(l*w*h): 900*900*750mm

- Hight: 1800mm

- Insulation thickness: 50mm

- Engine power: 4kw

- Shearing speed: 1460R/min

3.2 Water powder mixer

Description

Description

- Production capacity: 3T/H 2、Motor total power: 3KW

- Material for health level SUS304 material

- Equipment external dimensions: L × W × H = 1200 x 800 x 900.

3.3 Mixing tank – 500L

- SUS304 material, the outside diameter 900 mm, tank high 1600 mm

- Pu heat preservation, φ300 manhole, φ76 dust respirator, φ 32 feeding and discharge

- Temperature display instrument, liquid level display, stirring speed 35 rpm

- Tank capacity:500 L

3.4 Duplex filter

SUS304 material, smooth wall, no dead ends. Optional alternate use.

SUS304 material, 120 mesh.

3.5 Plate pasteuriz

Description: 5℃→65℃(homogenization) →85~95℃(15S) →5℃

This unit can be connected with separator, homogenizer, flash evaporator & degasser ect. this unit is used as Pasteurizer (widely used in fresh milk, milk beverage, juice, tea, alcohol, ice cream ect.) , and also pre-sterilize material when producing Pasteurized milk(long life milk).

This machine has features of high heat recovery, lower energy cost, strict design on the construction and easy operation, simple maintenance.

Technical Parameter

- Production capacity :1000L/H

- Heat exchanging area :8 ㎡

- Material inlet temperature :5-45℃, Material outlet temperature 5-50℃

- Sterilizing temperature :85-95℃, heat holding time:4-25 s

- Ice water consumption :5t/h

- Weight :880kg

- Size:1500*1500*1800mm

3.6 High pressure homogenizer

Description

Liquid homogenization, high pressure liquid transportation.

Technical parameter:

1·production capacity :1000 l/h, Piston root number:3

2·pressure :25mpa,Work continuously:0-20mpa

3·motor power :37kw

4·dimensionL*W*H :160*120*120cm 5·weigh :2100kg

3.7 Aging tank

- Material 304 stainless steel, thickness: 3mm

- Nominal volume: 1000L, diameter: Ø1150mm, insulation thickness: 50mm, total height: 2530mm, motor power: 1.1KW.

- Stirring speed: Optional speed: 35

- Manholes, digital thermometer, T-type cleaning head, rod outlet valve, adjustable cone feet, Export diameter: Ø38mm

3.8 Centrifugal pump

Description

Description

- Production capacity: 3T/H

- Motor total power:1.1KW

- SUS304 material

3.9 CIP return pump

Description

Description

316SS

ABB motor, power: 3 Kw.

Stainless steel casings.

Flow 10T/H

Head of 36 m

3.10 Freezing machine

- IN300L continuous freezing machine:

- Features:

- Continuous confession 502 with compressor

- Production capacity (liter or kg / h): ≤ 300 liters / hour

- Feed temperature ℃: ≤ 4

- Discharge temperature ℃: -4 Expansion%:

- 100 Refrigerant: F502 or 22

- Cooling consumption: 7500 kcal Motor Power KW: 11.25

- Dimensions (L × H × W) mm: 125 × 155 × 80

- Total weight Kg: 700

3.11 CIP return pump

Also known as colloidal pump rotor pump, clover pump shoes. Relying on two counter-rotating rotor synchronous (2-4 teeth) during rotation generated at the inlet suction (vacuum), thus conveying the material to be inhaled. Two rotors the rotor chamber separated into several small space, according to a → b → c → d order of operation. Operation to position a, only Ⅰ room full of media; to position b, B room closed off part of the media; to position C, A Room also closed the media; to position d, A Room with Ⅱ similarities, media incurs transported to the discharge. So the cycle, medium (material) is continuously transported out.

Specifications

Flow: 600-1320L / H

Motor power: 0.55kw

Inlet and outlet diameter: Ø25mm

4. Filling machine

SPECIFICATIONS

SPECIFICATIONS

· VOLTAGE:220V /1PH/ 50HZ

· POWER:200W

· AIR PRESSURE: ≥ 0.5Mpa

· AIR CONSUMPTION:0.2 m3 / min

· FILLING SPEED:20 TIINES /min

· NET WEIGHT: 165 KG

· OVERALL SIZE: 1020*820*1780 mm

· FILLING HEAD: 3 PCS

INJT multi-functional ice cream filling machine fill ice cream in cup.

The filling head can be customized according to client’s requirements.