Description

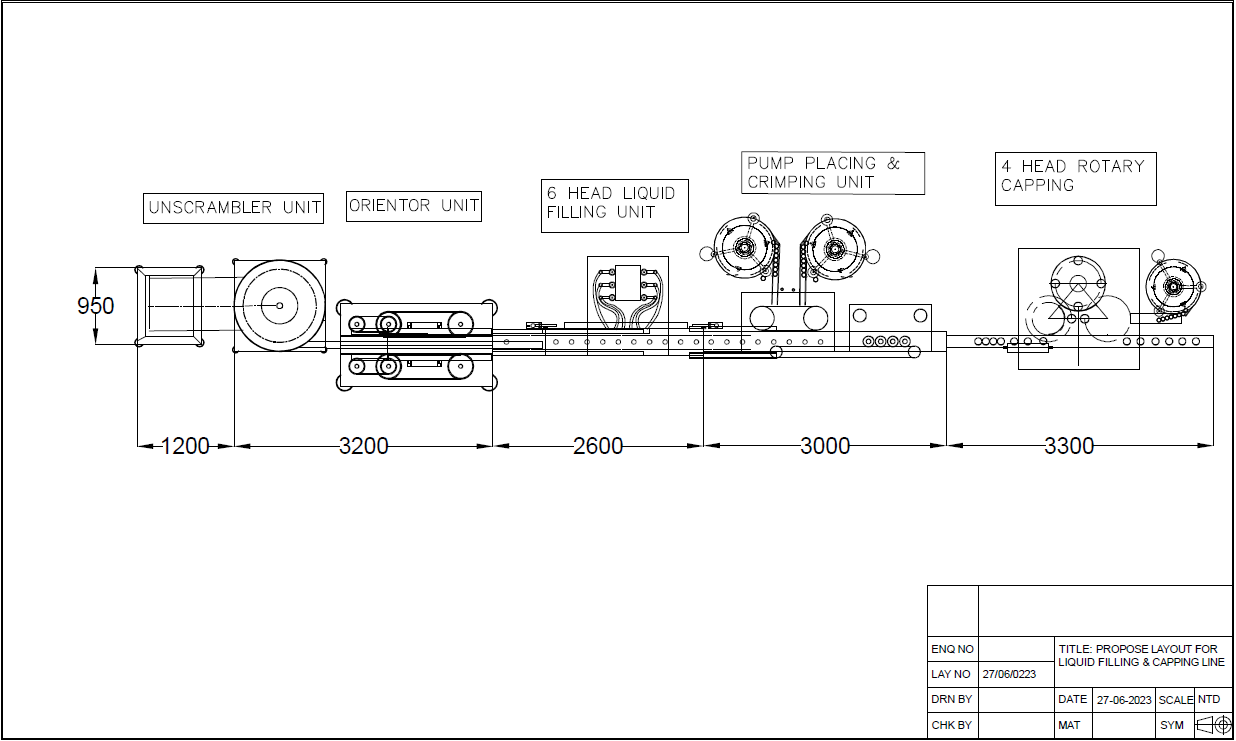

Quotation of Unscrambler, Orientor, Automatic 6 Head Liquid Filling Machine, spray pump placement and crimping Machine, 4-head Rotary Capping and case packer.

Our company specializes in the manufacturing and supply of a wide range of advanced packaging machines for various industries. We offer single carton over-wrapping machines, collating/bundling and over-wrapping machines, flow wrapping machines, shrink wrapping machines, powder filling/paste filling/liquid filling machines, foil sealing machines, capping machines, soap banding machines, sleeving machines, cartoning machines, and special-purpose packaging machines.

We are committed to providing our clients with innovative, high-quality packaging solutions tailored to meet their specific needs. Our team of experienced engineers and technicians provide comprehensive support and training to help our clients get the most out of their investment.

In addition to our up-gradation solutions for existing machinery, Inpakt also offers:

• Customization Services – We can provide customized solutions that meet your specific needs and requirements, ensuring that your machinery operates at peak performance.

• Maintenance and Repair Services – Our team of experienced engineers can provide maintenance and repair services to ensure that your machinery is always operating efficiently and effectively.

• Training Services – We can provide training services to your staff on the operation, maintenance, and troubleshooting of the machinery, to ensure that they can use it effectively and efficiently.

• Spare Parts – We can supply genuine spare parts for the machinery, ensuring that it continues to operate smoothly and efficiently.

• Turnkey Projects – We can also undertake turnkey projects for setting up new production lines, including the supply of machinery, installation, and commissioning, ensuring a hassle-free experience for our clients.

At Inpakt, we are committed to providing our clients with a comprehensive range of solutions that meet their every need.

Description of operation as below:

Operation – Filling Line

Description of operation as below:

Unscrambler: The bottles are fed into the packaging line through an unscrambler. This machine arranges the bottles in an orderly manner, ensuring a consistent and smooth flow of bottles for further processing.

Volumetric Filling Machine: The bottles are transferred onto a conveyor belt of the volumetric filling machine. The machine is designed for filling 30 ml of product into each bottle. The filling operation accurately measures and dispenses the desired amount of product into the bottles.

Spray Pump Placement and Crimping: The packaging line incorporates a specially designed mechanism to place and crimp the spray pump onto the bottles. The spray pumps are taken from a vibratory feeder chute and positioned onto the bottles with the help of a worm screw mechanism. The bottles are indexed to facilitate the pick and place assembly, which precisely drops the pump into the bottles. At the subsequent station, the crimping tools on the six heads securely crimp the pump onto the bottles.

Rotary Capping Machine: After the crimping process, the bottles move to a rotary four-head capping machine. This machine places the caps onto the bottles and applies the necessary pressure to ensure a tight seal. The rotary design allows for efficient and precise capping operations.

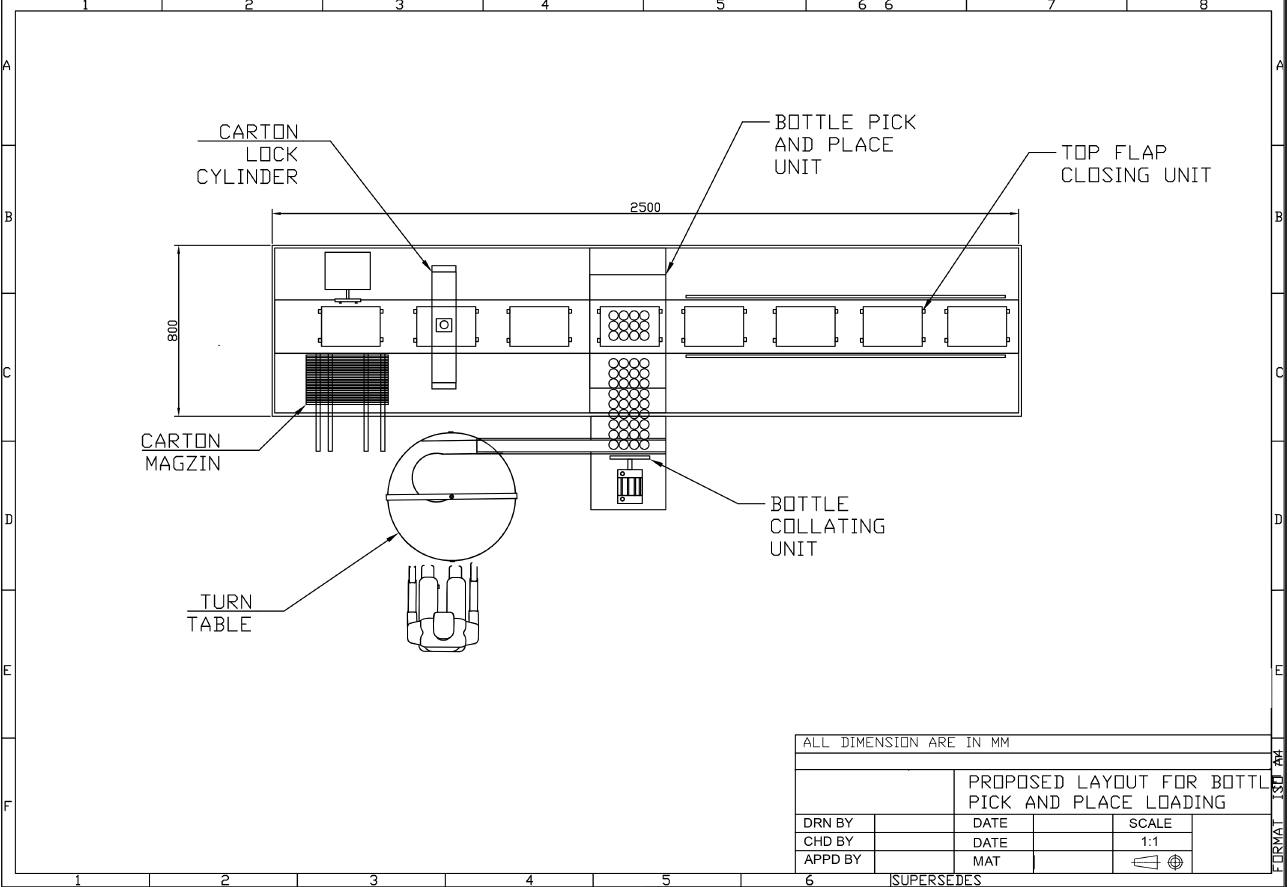

Case Packer for Small Cartons

Bottle Feeding: The bottles are fed from a turntable into the collating unit of the case packer. The turntable ensures a smooth and continuous flow of bottles for packaging.

Matrix Formation: The bottles are collated in a 4 x 3 matrix formation, where four bottles are aligned horizontally, and three bottles are aligned vertically. This arrangement maximizes the packaging efficiency and optimizes the use of carton space.

Carton Stacking: The cartons are stacked in a magazine, ready to be loaded with the collated bottles. The magazine ensures a steady supply of cartons for the packaging process.

Pocket Conveyor: Each carton is picked up from the magazine and opened on a pocket conveyor. The conveyor’s movement is indexing type, allowing precise positioning of the cartons for accurate bottle placement.

Pick and Place Assembly: A pick and place assembly is utilized to pick the collated bottles from the pocket conveyor and place them inside the open cartons. This process ensures precise and efficient placement of the bottles into the designated cartons.

Flap Closing and Tuck In: After the bottles are placed inside the cartons, the machine proceeds to close the carton flaps and securely tuck them in. This ensures proper sealing and protection of the packaged bottles.

The case packer for small cartons offers a seamless and automated packaging process, reducing manual labor and increasing productivity. Its precise bottle collation, accurate carton placement, and secure sealing make it an ideal solution for efficient packaging operations.

Automatic Linear Bottle Unscrambler

Overview:

• The Automatic Linear Bottle Unscrambler is designed to provide a loading solution for empty containers and delivers them to the downstream equipment conveyor in upright condition after orientation.

• Machine has a very robust and vibration free body built on a sturdy welded S.S. 304 frame.

• And having S.S. 304 container contact parts ensures durability and cGMP compliance.

• User friendly and variable speed controls for orientor and conveyor, make the bottle orientor easy to adjust and able to handle different bottle sizes and shapes.

The above image is for representation purpose

Automatic Linear Bottle Unscrambler

Operation:

• Empty containers are loaded into the easy access bulk hopper.

• An elevator lifts the empty containers from the bulk hopper and deposits them into the centrifugal feeder. In the feeder containers are moved to the outside of the bowl and dropped into the tooling channel.

• The tooling channel will ensure the container is in the proper position to enter the spacing belt. The spacing belt maintains positive control over the containers and ensures properly timed containers enter the orientation belt work area.

• Spacing belt will determine the overall speed of the machine.

• As the containers enter the orientation area, gripper belts pull the container, and the hook will raise the container in an upright position if the neck is exposed.

• Bottom exposed containers will pass through, and all reach the pivot block then.

• Pivot block forces the containers to orient upright. Containers then pass from the gripper belts towards the exit belt.

• Secondary landing plate keeps doing minor adjustments in orientation of the upright containers until it is delivered on to the next conveyor.

Technical Specifications

| Output/Min* | Upto 80 BPM

(Depends on Container size & container characteristics) |

| Direction of Movement | Left to Right |

| Electrical Specification | |

| Un- scrambler Motor | 1 HP / 415 volt / 50 Hz / 1350 RPM |

| Bottle Elevator Motor | 1 HP / 415 Volt / 50 Hz / 1350 RPM |

| Orientation Drive | 1 kW x 6 Nos. |

| Un- scrambler Motor | 1 HP / 415 volt / 50 Hz / 1350 RPM |

| Height of Conveyor** | Height of Conveyor** |

| Input Specifications | |

| Container Diameter | 25 mm to 100 mm (29mm for 25ml, 32 mm for 50ml) |

| Container Height** | 58 to 210 mm (87 mm for 25ml & 98 mm for 50ml) |

| Utility Requirement | |

| Electrical supply | 3∅ + Neutral + Earthing |

| Electrical load | 1.3 KW |

| Air Consumption | 0.5 CFM @ 6 kg (not in our scope of supply) |

| Silent Feature

• Robust and vibration free construction |

|

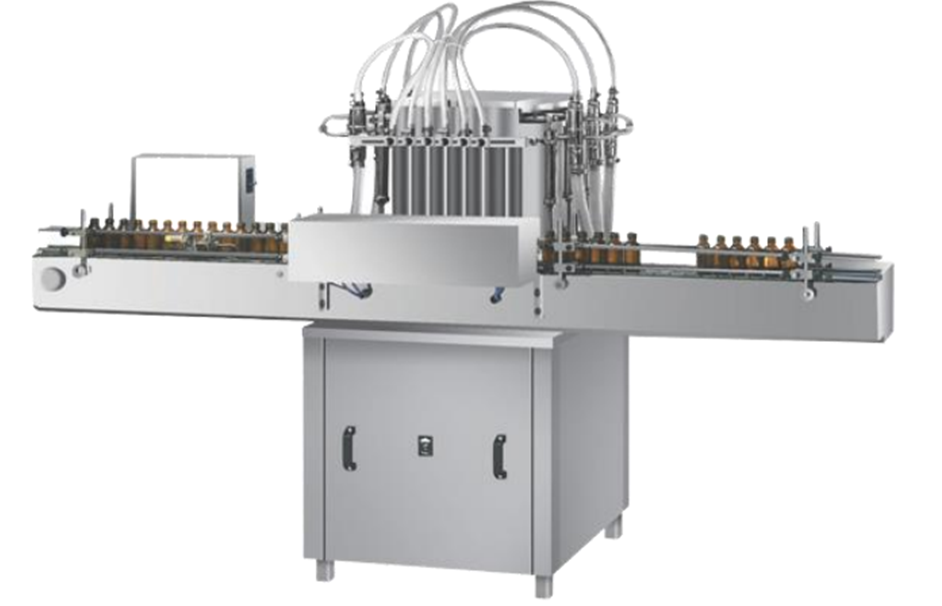

Automatic 6 Head Liquid Filling Machine

CONSTRUCTION

The machine base is fabricated from good quality steel. The top plate is clad by SS-304 table top. All the liquid contact parts will be of SS-316 / Teflon / Nylon / PVC

FEATURES

There are total Six set of filling heads in the machine. A set of filling system includes nozzle and syringe of required dose. The nozzles are adjusted to match the container centre distance.

Dose can be adjusted by adjusting stroke length of piston as per requirement manually. The machine will come with syringes (6 nos.) suitable for dose from 30 ml to 100 ml, which is called as filling change parts. For different dose, required additional set of change parts.

images are for representation purpose and may change

Liquid Filling Machine

Technical Specifications

| Product |

Spray |

| Speed | : Up to 80 BPM |

| Dose | 30 ml |

| Accuracy | : + 1% |

| Contact Parts | : SS-316 / Teflon / Nylon / PVC |

| Control | : Switchgears of Schneider or equivalent make |

| AC Drive | : DELTA or similar make |

| Dimension of conveyor | 10 ft. L x 4 ft. W x 5.5 ft. H (approx.) |

| Body structure | SS304 |

| Gearbox and motor | Standard Indian make |

| Conveyor length | 10 feet. (Approx.) |

| All Wiring | Schneider. |

| UTILITY REQUIRED | |

| Power Required | : Single Phase, 230 V, 50Hz, 1 PH, 3 HP With Proper Earthing |

| Compressed Air | : 5 – 7 kg/cm3

(Compressor is in buyer’s scope |

Spray Pump Placement and Crimping

Technical Specifications

| Product | Spray Perfumes |

| Output | Upto 80 BPM |

| Bottle | |

| Cap | |

| Power Transmission | Simplex chain /gears /Timing belt |

| Conveyor Chain | Plastic straight running slate chain |

| Conveyor motor | ¼ hp 1400 rpm (make Bonofinlioli) |

| Bearings/liner guides | SKF/ Nachi / Hiwin |

| Simplex chain | Rollon / Diamond |

| Conveyor Gear box | B28 (make Delta) |

| Pneumatic components | Festo Make |

| Pneumatic cylinders type | Double Acting Cylinder |

| All control | through PLC/HMI |

| Contact parts | S.S, Aluminum/ plastic |

| Non-contact parts | MS/plastic /S.S. |

| Parts finishing | Hard chroming/ENP/Buffing/Anodizing |

| Mechanical Indexer | Cam Field make / subject to availability |

| Turret | 8 nos. of Pocket, PP /Nylon /Delrin |

| Vibrator | 3 nos. Vibrotech |

| Cap Transfer chute | S.S chute |

| Machine main Motor | 1/2 HP 1400 rpm (make Hindustan.) |

| AC Drive | 1/2 hp (make Delta (2nos.).) |

| Machine main Gear box | B28mm make Bonofinlioli |

| Safety Guards | Available for moving parts |

| Bottom cover | Available S.S Frame with easily Removable |

| Feed height | 850MM ±50mm |

| Safety Interlock | Bottle jam – machine stop

no bottle – no nozzle (Bung) system |

| Prices | Sr. no | Description of machine/Equipment | Unit Price |

| 1. | Unscrambler and Orientor of bottles | ||

| 2. | 6 Head linear volumetric Liquid Filling Machine (Mechanical Type)

|

||

| 3. | Spray Pump Placing and Crimping Unit | ||

| 4. | 4 Head Rotary Capping Machine | ||

| 5. | Installation & Training charges | ||

| 6. | Freight, Forwarding & Clearance | ||

| 7. | Insurance, Inspection & Certification | ||

| TOTAL EXCLUDING VAT | |||

| 8, | OPTIONAL: Automatic Case packer with Collate pick and place unit |