Description

Fruit Juice Bottling Line

| SUB: LIQUID BOTTLING LINE FOR BONZ ICE TEA (1300BPH-500ml PET, 38mm cap screw cap)

Scope: Water treatment RO system, Mixing tank, feed holding tank, semi auto rinser, automatic filler, automatic cap torque, shrink sleeve tunnel, date batch coder, out-feed collection table. |

COMMERCIAL OFFER :- FILLING LINE FOR LIQUID ENERGY ICED TEA (BONZ)

| Sr.

No. |

Description | Qty | Unit

Price |

Total

Price |

| 1 | RO water treatment 500LPH | 1 set | ||

| 2 | 1000L stainless steel mixing tank | 1 set | ||

| 3 | 1000L holding tank for filling | 1 set | ||

| 4 | 12 head manual bottle rinser | 1 set | ||

| 5 | Auto inline 4 head piston filler (1300BPH) | 1 set | ||

| 6 | Auto inline screw capper (38mm plastic cap) | 1 set | ||

| 7 | Electric shrink sleeve tunnel | 1 set | ||

| 8 | Date batch coding machine | 1 set | ||

| 9 | 6m out feed bottle conveyor | 1 set | ||

| 10 | Outfeed collection table 1m x 700mm | 1 set | ||

| 11 | Semi manual shrink wrapper | 1 set | ||

| 12 | Stainless steel pipe work from tank to filler from CIP to tanks to filler

approx. according to factory layout |

40m | ||

| 13 | CIP system pump (clean in place)

pour in water and mix at 0.5% of volume – pump for 30 mins rinse. Mix Peroxide 0.2% of volume for 10 mins drain |

1 set | ||

| Services | ||||

| 14 | Delivery – ex works Pretoria |

—— |

||

| 15 | Project management, installation & commissioning

(Excluding transport & accommodation) |

|||

| TOTAL | ||||

OPTIONALS

| 6 | Auto feed cap hopper – | 1 set | ||

Water treatment Reverse Osmosis 500LPH

Grouping 1 – Raw Water Pump to R.O output consists of the following items.

Quote 1 price for the entire block…* Raw water tank from Municipal Jojo 5000L

1.) Supply pump to R.O 220V 0.75 Kw Stainless – R4325

2.) R.O Pre-filtration 2000 lph Sediment & Carbon with media and Digital backwash heads R21 067

3.) Antiscalent system for R.O (used instead of a softener ) 200 Liter tank with 7 bar dosing pump @ 5lph

4.) Industrial High Recovery system >75% 500 lph

5.) product Tank stainless you must Supply.

Grouping 2- CIP tank & Pump,

Grouping 3- Cold Plasma UV Germicidal System for product water from R.O tank, 5 Micron 20″ Housing & Filter (policeman filter in case of sediments in the R.O product water tank)

2 x membranes for the R.O .

| 1000lt Stainless Steel Mixing Tank | |

| Details | Description |

| Capacity: | 1000lt |

| Material of construction: | Stainless Steel SS304L |

| Position of vessel: | Vertical |

| Bottom Configuration: | 15° Conical with Knuckled Radius |

| Leg Details: | 4 x Stainless Steel Pipe Legs with Base Plates |

| Top Configuration: | Flat with Hinged Lid |

| Mixer Details: | Top mounted geared Mixer unit, 2.2KW, 380 Volt, complete with Solid Stainless-Steel Shaft and Mixing Impellor Set with bottom support spider |

| Fittings: | 1 x DN65 Male Outlet |

| Diameter | 1000mm |

| Shell Height | 1250mm |

| Vessel Finish: | Polished Finish |

12 head manual bottle rinser

The bottling process begins with the empty bottles placed upside down on the rinse nozzles. The operator pushes the rinse button to start a pre-timed rinse. When the rinse stops, the operator transfers the bottle to the filling line conveyor

- Rinses 0.2L to 2000ml bottles

- Capable of rinsing up to 3000 bottles per hour (500ml)

Automatic Filling Machine FLSA-1000P

Piston Filler measure and dispense paste and liquid products – thin and/or moderately dense liquids – onto a container. Each machine is equipped with two volumetric pistons. Each fill/release cycle consists of an intake stroke, where the product is withdrawn from the container or hopper and taken into the product cylinder. The down stroke commences as soon as the product cylinder has reached its predetermined fill level. The piston pushes the product out of the cylinder and into the container.

The amount of product to dispense is set by a simple adjustment of the length of the piston stroke (the distance covered by the piston). The adjustment is performed by turning a small adjusting wheel located at table-top level. If the stroke is reduced the volume of dispensed product decreases. On the other hand, lengthening the piston stroke will result more product being dispensed. Once the machine is set, the piston filler will dispense accurately and repeatedly.

Picture for reference only –

Features:

Filling Range: (100-1000ml) each filler.

Approximate Speed: 1200 pcs/hour

Stainless Steel Construction (SS 304)

Pneumatic operation.

Max temperature of the liquid: 80C

Piston Feed, Speed Adjustment

Accuracy (+/- 1%)

Sanitary Stainless-Steel Quick Disconnect Fittings

Hopper’s capacity: 72 litres, can be direct feed from product tank

Other specs

Voltage: 110VAC / 50-60 Hz / 1Ph

Air Requirements: 4 CFM/min (114 lts/min) @ 90 PSI (6.2 Bar) (Air compressor not included)

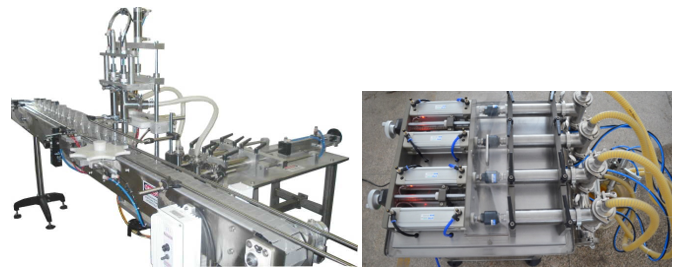

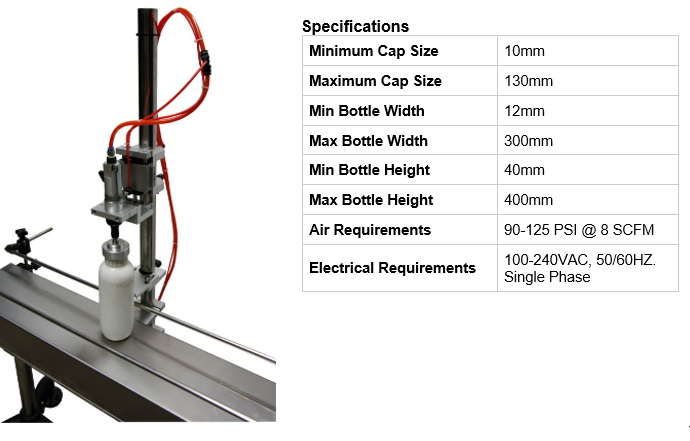

Auto Torque Capping Machine

Automatic screw capping machine that mounts to an existing conveyor. At a rate of up to 40 caps per minute, the capper tightens caps from 10 – 130mm in diameter, and accommodates bottles from 12mm – 300mm wide. We designed the Inpakt torques capper to provide our customers with a completely turn-key, self-contained, and easy to adjust automatic bottle capping machine.

Features

Up to 40 Caps Per Minute

Easy to Set-up. Easy to Adjust

External Torque Adjustment Dial

Excellent Repeatable Torque Accuracy

Electric Shrink Sleeve Label Heat Tunnel 1000MPA

MACHINE FEATURES

Frame: Heavy duty mild steel

Finish: Powder coated (Goose grey and red structure)

Heat Chamber Dimension

Length: 2000mm

Width: 200mm

Height: 300mm

Speed: Up to 100 BPM

PLC: Delta DVP 14

VSD: Yaskawa

Conveyor: High Heat Modular

Switch Gear: Lovaio

MCB: Hager

Heating Capacity: 12 Kw

Geared Motors: Motovario Italy

Electrical Requirements: 38OVolts 3 phase neutral earth. (25 amps per phase)

Semi manual shrink wrapper – For 6 packs to 24 pack

Frame-Heavy duty mild steal

Finish-Powder coated

Sealing System- Impulse heat-sealing system, air operated to ensure smooth

operation and constant sealing pressure.

Hot Box-900mm heat chamber

PLC-Delta

Conveyor-Galvanized wire mesh

Switch Gear Lovato

Sensors-Omron

MCB-Hager

Heating Capacity-18kw

Control Station LCD display keypad with fault on screen and audio beep on any fault

Machine Dimensions L2900 / W1500 / H2000mm

Offer to supply-Manually infeed combination sleeve sealer and shrink tunnel with opening dimensions of

650 wide x 400mm high our Model 58SM4

Electrical requirement-380 Volts 3 Phase Neutral and Earth. (45 amps per phase).

Compressor requirement-Cleon source of dry air at 500 KPA (100 It. free air per minute).

Ink Jet Date Batch Coder

- 7-inch colour touchscreen display

- Supports up to 2 print heads

- Independent controller separated from the print heads, suitable for various working environments

- Printing height up to 25.4mm (1.0″)

- Low periodical maintenance

- Clean and trouble-free technology

- User-friendly interface

- Easy integration into any production environment

- Easy adjustment for down and side printing

- Printing on porous or non-porous surface

- Ability to backup settings, logos, and messages

- User level password protection

- Automatic recognition of inks (aqueous or solvent) and application of appropriate printing parameters

- Controller stores up to 500 messages internally

- Ethernet and USB connectivity

- PC software for message template design

- Printing speed up to 60m/min (200ft/min)

- Resolution up to 600 x 600 dpi