Description

FILLING AND PACKAGING MACHINES

SCOPE OF OFFER: Essential Oil Filling and Capping Machines for the following range of containers

Line 1: 330ml glass at 2000BPH – Including jars, spray bottles etc

Line 2: 30ml dropper bottles at 2500BPH – Including 9ml Nano-shots / auto cap torque, manual cap placement

Line 3: Semi-automatic equipment for all of the above containers except for ROPP metal cap capping.

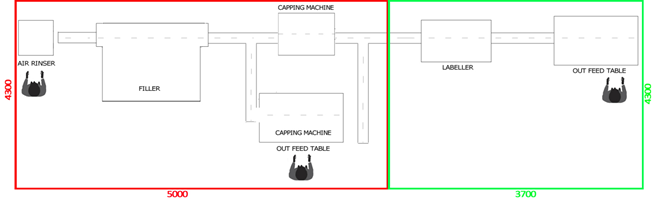

LINE 1: For 330ml water bottles, 200ml pump bottles and 100ml Jar

Total line length & width inside the clean room 6.5*4.5m

Process for 330ml glass bottle with aluminium caps

- Semi auto bottle air rinser: Bottles are manually rinsed and placed on the conveyor

- Filling station: The bottles move to the four head piston filler which get stopped buy a gating system to be filled with pneumatic piston pumps,

- Capping for metal caps: Caps are then automatically placed and formed onto the bottle

- Outfeed conveyor: AC motor 1 -meter outfeed

- Labelling applicator: Side around self-adhesive sticker machine, apply label to containers

- Accumulation rectangle table: Bottles are sent to the outfeed collection table to be shrink wrapped and boxed.

Process for the jars and the pump bottles etc

- Semi auto bottle air rinser: Bottles are manually rinsed and placed on the conveyor

- Filling station: The bottles move to the four head piston filler which get stopped buy a gating system to be filled with pneumatic piston pumps.

- Capping station: Containers get diverted to semi auto capper, capped and then manually transferred back onto the automatic line to get labelled and packed

- Labelling applicator: Side around self-adhesive sticker machine, apply label to containers

- Accumulation rectangle table: Bottles are sent to the outfeed collection table to be shrink wrapped and boxed.

1) Bottle Air Rinser / 6 head

Picture for reference only

Application

The easy to operate manual air rinser is ideal for smaller facilities that manually rinse containers prior to filling. The operator of the bottle rinser simply steps on a footswitch to activate the rinse cycle. The container is then rinsed for a pre-set amount of time.

- Easy operation

- Air filter

- 4 Rinse Nozzles

- Foot switch activation

- Electronic timer

2) Automatic 4 head Linear Piston Filler

Automatic 4 Head Piston Filler (Linear type)

- Individual/simultaneous volume adjustment.

- Filling speed adjustment.

- Adjustable Nozzle Pitch and height.

- Intermediate tank with pneumatic level float.

- Robust design.

- Electric control with pneumatic operation.

- Contact parts in S/S 316.

- No bottle no fill facility.

Specifications

- Size 2500mm w x 1400mm d x 1700mm h

- Weight (approx.) 240kg

- Air Pressure Required 600 kPa

- Air Consumption 10C FM

- Speeds, approx. 20-40 BPM

- Filling Range 50ml to 500ml optional 100ml to 1000ml (double stroke for higher volumes)

Options

- Additional sizes of interchangeable product cylinder and piston assemblies

- Twin manifold and suction hose inlet

3) ROPP Metal Cap, Capping Machine

Machine designed to place and form metal caps on a wide range of containers – enclosures.

- Capacity: <2500 bottles per hour

- Power: 400 V, 3 phase, 50 Hz

- Dimensions: Length 1200 x Depth 1070 x Height 2400 mm

Cap & Bottle Requirements:

- Cap type: Aluminium

- Bottle type: cylindrical glass

- Bottle Ø: min 55 – max 115 mm

- Bottle height: min 140 – max 380 mm

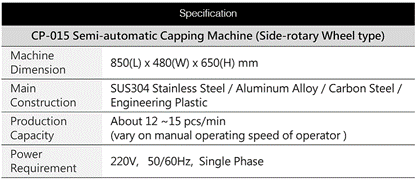

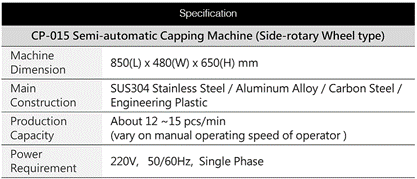

4) Semi-Automatic Capping Machine

Application

- Side-wheel capping by 4 side-rotary wheels, suitable for various specialty caps, such as Spray / Pump /

- Glass Jars / Tamper Resistant Caps, etc.

- Suitable for Flat / Square / Oval Bottles and other special shape of bottles.

- Most suitable for various bottles & caps with small production

Features

- Capping torque can be easily adjusted.

- Changeover or adjustments are fast and simple without using any tools.

- Less maintenance with durable life, the best choice of capping machine.

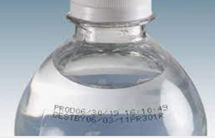

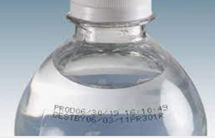

5) Ink Jet Date Batch Coder – Cartridge Type

- 7-inch colour touchscreen display

- Supports up to 2 print heads

- Independent controller separated from the print heads, suitable for various working environments

- Printing height up to 25.4mm (1.0″)

- Low periodical maintenance

- Clean and trouble-free technology

- User-friendly interface

- Easy integration into any production environment

- Easy adjustment for down and side printing

- Printing on porous or non-porous surface

- Ability to backup settings, logos, and messages

- User level password protection

- Automatic recognition of inks (aqueous or solvent) and application of appropriate printing parameters

- Controller stores up to 500 messages internally

- Ethernet and USB connectivity

- PC software for message template design

- Printing speed up to 60m/min (200ft/min)

- Resolution up to 600 x 600 dpi

6) Self-Adhesive Labelling Machine

Application

Applying self-adhesive labels on round bottles

Specifications

- Speed 0-80 PCS/min

- Bottle diameter Ф 20 – Ф 100mm

- Bottle Height 25-300mm

- Label size wide 10-140mm

- Label size length 15-200mm

- Labeling precision + 1mm (depending on the bottle degree, perpendicular round)

- Labeling Maximum diameter 200mm

- Power supply AC110V / 220V. 0.5KW

- Machine size 1430*1050*940mm

- Weight 100kg

- Printing device HP 260Q -(optional)

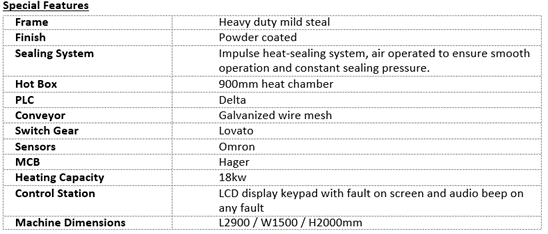

7) Semi-Automatic Shrink Wrapper

Offer to supply

Manually infeed combination sleeve sealer and shrink tunnel with opening dimensions of 850 wide x 400mm high our Model 58SM4

Electrical requirement

380 Volts 3 Phase Neutral and Earth. (45 amps per phase).

Compressor requirement

Cleon source of dry air at 500 KPA (100 It. free air per minute).

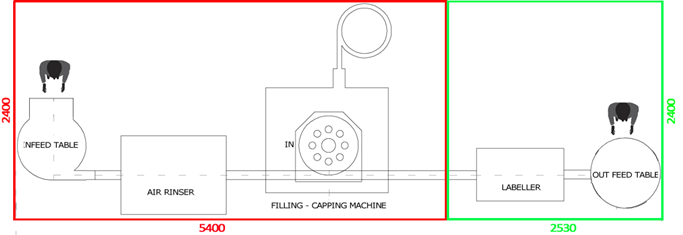

LINE 2: for 30ml dropper glass bottle & 9ml Nano shot

Total line length & width inside the clean room 6m*4m

1. Infeed round table: Speed variable infeed table to sort and orient to line empty glass bottles.

2. Bottle air rinser: Clean air jet and vacuum suction.

3. Filling station: Two high speed servo driven peristaltic pumps accommodated on machine, separated controlled by PLC touch screen, the volume adjustable by touch screen.

4. Dropper bowl: Vibrating bowl to sort and orient glass dropper.

5. Dropper inserting system: Automatic robotic arm pick and place dropper to a glass bottle.

6. Sensor check station: Infrared sensor check availability of dropper inside cup.

7. Capping revolving system: Servo drive device for capping cup with dropper.

8. Discharge station: Mechanically drive discharge device.

9. Outfeed conveyor: AC motor 1.5-meter outfeed conveyor.

10. Labelling applicator: Side around self-adhesive sticker machine, apply label to glass bottle.

11. Sleeve shrink machine: Applicator for safety seal film on top of bottle.

12. Accumulation round table: Speed variable table to accumulating ready glass bottles.

1) Infeed Accumulation Rotary Tables

Picture for reference only

Specifications

• Turning table diameter 800 mm.

• Stainless steel AISI 304

• Speed:30-60 cans/minute.

• 1100×800×1160 mm.

2) Bottle Air Rinser / 6 valves

Bottle Air Rinser is Equipped with powerful clean air jet and vacuum suction

Extra change parts required for different diameter bottle mouth opening

Containers are indexed into the rinse area based on the number of dual action nozzles on the machine. Nozzles descend to bottles and first blast the inside of the bottles with air to loosen dust and debris. Dual action nozzles then seal on the container and vacuum out the debris to an easily removable and cleanable waste reservoir. Containers are then returned to the conveyor to be moved down the packaging line.

• Frames made of 304 stainless steel and aluminium

• PLC controls

• Air filter filtration system

• Vacuum dust suction nozzles

• Stainless steel levelling legs

• Manual height adjustment

• Automatic pin-style indexing

• Photo sensor/counter system to ensure containers are in place prior to rinsing

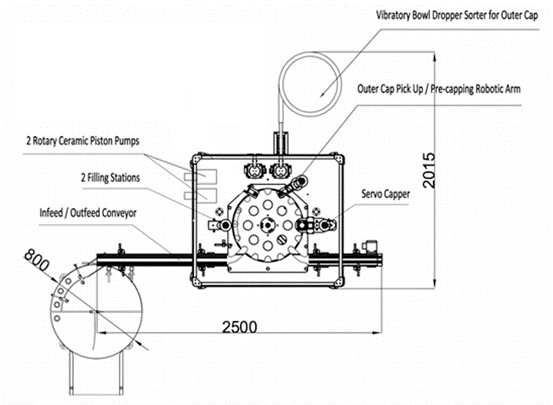

3) Filling & Capping Machine

Filling station: Two high speed servo driven peristaltic pumps accommodated on machine, separated controlled by PLC touch screen, the volume adjustable by touch screen.

Dropper bowl: Vibrating bowl to sort and orient glass dropper.

Dropper inserting system: Automatic robotic arm pick and place dropper to a glass bottle.

Sensor check station: Infrared sensor check availability of dropper inside cup.

Capping revolving system: Servo drive device for capping cup with dropper.

Discharge station: Mechanically drive discharge device.

Outfeed conveyor: AC motor 1.5-meter outfeed conveyor.

| # | Product | Form | Dimensions (mm) | Fill Volume | Description |

| 1 | Glass bottle with dropper | Round | TBD | 10 – 50 ml. | TBD |

| MACHINE PARTS | All the product contact parts are stainless steel AISI 304 . The machine is constructed of

stainless steel, anodized aluminium and plastic. |

| CERTIFICATION | FDA, CSA Compliant. |

| POWER CONSUMPTION | 220 V, 50 Hz, FLA 25-amp, Power consumption 2 KW |

| AIR CONSUMPTION | Pressure –0.5-0.6 Mpa Air consumption – 0.3m3/minute |

| MACHINE DIMENSIONS | LxWxH 2500x1200x2050mm. |

| UTILITIES | All utilities such as: gas, hydro, water, exhaust, e.t.c. are to be supplied by the customer. |

| DRAWING | Attached |

4) Ink Jet Date Batch Coder – Cartridge Type

• 7-inch colour touchscreen display

• Supports up to 2 print heads

• Independent controller separated from the print heads, suitable for various working environments

• Printing height up to 25.4mm (1.0″)

• Low periodical maintenance

• Clean and trouble-free technology

• User-friendly interface

• Easy integration into any production environment

• Easy adjustment for down and side printing

• Printing on porous or non-porous surface

• Ability to backup settings, logos, and messages

• User level password protection

• Automatic recognition of inks (aqueous or solvent)

and application of appropriate printing parameters

• Controller stores up to 500 messages internally

• Ethernet and USB connectivity

• PC software for message template design

• Printing speed up to 60m/min (200ft/min)

• Resolution up to 600 x 600 dpi

5) Self-Adhesive Labelling Machine

Application

- Applying self-adhesive labels on round bottles

Specifications

- Speed 0-80 PCS/min

- Bottle diameter Ф 20 – Ф 100mm

- Bottle Height 25-300mm

- Label size wide 10-140mm

- Label size length 15-200mm

- Labeling precision + 1mm (depending on the bottle degree, perpendicular round)

- Labeling Maximum diameter 200mm

- Power supply AC110V / 220V. 500W

- Machine size 1430*1050*940mm

- Weight 100kg

- Printing device HP 260Q -(optional)

LINE 3: Semi-automatic equipment

- Bottle air rinser: Bottles are manually rinsed and placed on the conveyor

- Piston Filler: To fill liquids and creams at a rate of around 500BPM.

- Peristaltic pump filler: To fill liquids from 5ml to 50ml

- Semi auto labeller with foil ribbon: For self-adhesive labelling

- Accumulation rectangle table: stainless steel tables, work surface for semi auto section

1) Bottle Air Rinser, Table top / 4 head

Application

The easy to operate manual air rinser is ideal for smaller facilities that manually rinse containers prior to filling. The operator simply presses a button to activate the rinse cycle. The container is then rinsed.

- Easy operation

- Air filter

- 4 Rinse Nozzles

- Pressure activation

- Electronic timer

2) Piston Filler – 100ml-1000ml

Machine Description

The Inpakt FILT-1LC Series of semi-automatic liquid, cream and paste filling machines offer a simple to operate heavy duty design with a proven history of reliability and ease of use and cleaning.

The versatility of this all-pneumatic machine has now been enhanced with a completely new compact design volume adjustment and cylinder assembly incorporating a rotary valve system.

The valve system handles bottling products from thin liquids to creams and thick pastes, it will even products with soft suspended solids, a task previously requiring 2 different types of filling machine or expensive change parts.

The new cylinder design enables quicker dismantling and easier, more thorough cleaning of wet parts. Various product supply methods can be used according to the nature of product or customer preference e.g. close coupled hopper, suction hose inlet assembly, elevated or floor level tank, and low-pressure feed from a pump.

The stroke adjuster and air/product cylinder drive assembly are enclosed by a safety interlocked polycarbonate cover.

- Heavy duty pneumatic product cylinder drive system

- Integral 304-grade stainless steel base and cladding for bench or trolley mounting.

- Suitable for warm water hose down

- Wetted parts manufactured from 316-grade stainless steel and food grade engineering plastics

- Product piston fitted with O-ring energised Teflon/HDPE glide ring seal

- Quick connect Triclover product inlet/outlet fittings

- All pneumatic flameproof operation suitable for use with flammable products

- Individual fill speed and recharge speed controls

- Asset Rotary Product Valve system provides a positive valve seal unaffected by product supply head height

- Available in 50, 125, 250, 500, 1000mL or 2000mL maximum capacity cylinder sizes

- Product cylinder and valve dismantle by hand for cleaning – no tools require

- Filling accuracy +/- 0.5 or better

Specifications

- Width: 820mm / Height: 330mm / Depth: 330mm

- Weight: 35Kg

- Air Pressure Required: 600KPa

- Air Consumption: 8CFM

- Minimum Container Volume: 100mL / Maximum Container Volume: 1000mL

- Filling Nozzles: 1

- Operation Mode: Semi-Automatic

- Machine Type: Liquid, Cream, Paste Filling

3) Peristaltic Pump Filler – 5ml-50ml

Tabletop Peristaltic Pump Liquid Filling Machine is the best system to avoid contamination, product is only in contact with the medically approved tubing and the nozzle, against cross contamination and easy cleaning. Without having to change anything but the dimension of the tubing in use. The target market is small to medium-sized batch production that requires flexibility, high precision and efficiency.

- Easy to set, even if the novice can also with ease

- With peristaltic pump, product is only in contact with the tubing

- Made of SUS 304 stainless steel, meets cGMP requirement

- LED display, easy adjusting filling volume, speed and between filling

- Draws liquids directly from a tank or drum, or add a hopper if need

- Without any change parts other than tubing

- Three operating modes: manual, intermittent filling or foot switch

Specifications

- Power: single phase 110/220VAC, 50/60Hz

- Filling Range: 5~50ml

- Filling Speed: 5~50ml/sec

- Accuracy: 0.5%~1%

- Machine Dimensions: (L)360mm (W)580mm (H)325mm

(For reference only, the real drawing should be considered as final.)

4) Semi-Automatic Capping Machine

Application

- Side-wheel capping by 4 side-rotary wheels, suitable for various specialty caps, such as Spray / Pump /

- Glass Jars / Tamper Resistant Caps, etc.

- Suitable for Flat / Square / Oval Bottles and other special shape of bottles.

- Most suitable for various bottles & caps with small production

Features

- Capping torque can be easily adjusted.

- Changeover or adjustments are fast and simple without using any tools.

- Less maintenance with durable life, the best choice of capping machine.

5) Tabletop Labelling Machine with Ribbon Printer

Labelling machine for round bottle labelling and date batch coding

Technical parameters

| Voltage | 220V 50Hz |

| Power | 220W |

| Label speed | 25-50 pcs/min |

| Label accuracy | ±0.5mm |

| Label Roll inner diameter | ≥ 75mm |

| Max. label roll out diameter | ≤ 275mm |

| Bottle diameter | 20mm-120mm |

| Width of Label | 26-150mm |

| Length of label | 25-280mm |

| Printer | No |

| Machine Size | 65*45*65cm |

| Gross weight | 35kg |

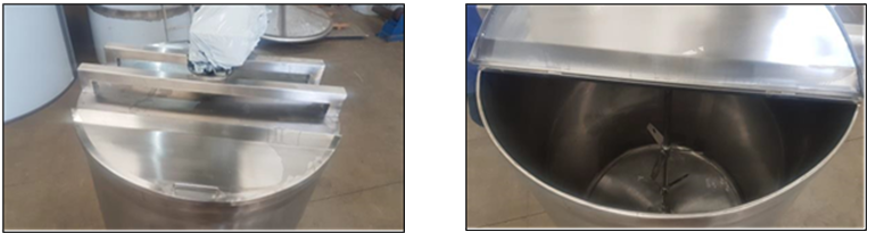

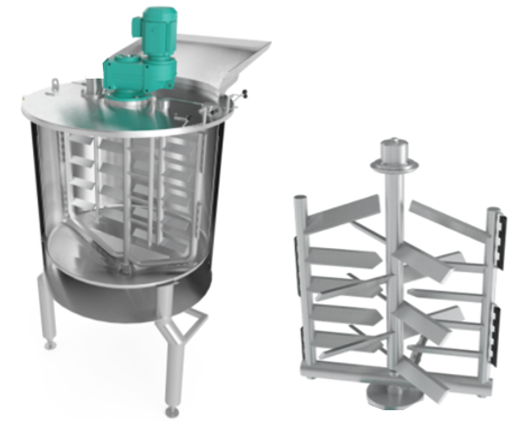

6) 200L Blending Tank for Liquids, Creams, Gels with scraper multi- paddle Agitator.

| 200lt Stainless Steel Mixing Vessel | |

| Details | Description |

| Capacity: | 200lt |

| Material of construction: | Stainless Steel SS316L |

| Position of vessel: | Vertical |

| Bottom Configuration: | 15° Conical with Knuckled Radius |

| Leg Details: | 3 x Stainless Steel Pipe Legs with Base Plates |

| Top Configuration: | Flat with Hinged Lid |

| Mixer Details: | Top mounted geared Mixer unit, 2.2KW, 380 Volt, complete with Solid Stainless-Steel Shaft and side wall scraping agitator with paddles, top mounted, set with bottom support spider |

| Fittings: | 1 x DN65 Male Outlet |

| Diameter | 650mm |

| Shell Height | 625mm |

| Vessel Finish: | Polished Finish |

7) 1000L Blending Tank for Liquids slow agitation

| 1000lt Stainless Steel Mixing Vessel |  |

|

| Details | Description | |

| Capacity: | 1000lt | |

| Material of construction: | Stainless Steel SS316L | |

| Position of vessel: | Vertical | |

| Bottom Configuration: | 15° Conical with Knuckled Radius | |

| Leg Details: | 3 x Stainless Steel Pipe Legs with Base Plates | |

| Top Configuration: | Flat with Hinged Lid | |

| Mixer Details: | Top mounted geared Mixer unit, 2.2KW, 380 Volt, complete with Solid Stainless-Steel Shaft and Mixing Impellor Set with bottom support spider | |

| Fittings: | 1 x DN65 Male Outlet | |

| Diameter | 1000mm | |

| Shell Height | 1250mm | |

| Vessel Finish: | Polished Finish | |