Description

EDIBLE OIL BOTTLING LINE

SCOPE OF OFFER

FILLING CAPPING AND LABELLING MACHINES FOR EDIBLE OIL

4-8 /20L per minute, 8-15/10L per minute, 20-25 5L per minute

Price List

| Machine Description | Qty | Price | Total | ||

| Lobe pump filling machine INP-6FLP – 6 head lobe pump filler

20L – 8BPM / 10L – 15BPM / 5L – 20BPH |

1 set | ||||

| Capping Machine CP114 – Pick & Place | 1 set | ||||

| Extra capping hopper and cap chuck for different size cap | 1 set | ||||

| Labelling Machine LBL558 – Self Adhesive, single side labeller | 1 set | ||||

| Tourmaline – Cartridge type printer | 1 set | ||||

| Conveyor system (plastic slat conveyor) | 10m | ||||

| Out feed roller conveyor | 5m | ||||

| Sub Total Equipment | |||||

| SERVICES | |||||

| FAT | Included | ||||

| Machine Crating | |||||

| CIF Douala Cameroon + internal logistics | |||||

| Project management – assembly / testing / personal training | |||||

| Sub Total Services | |||||

| Equipment | |||||

| Services | |||||

| Total | |||||

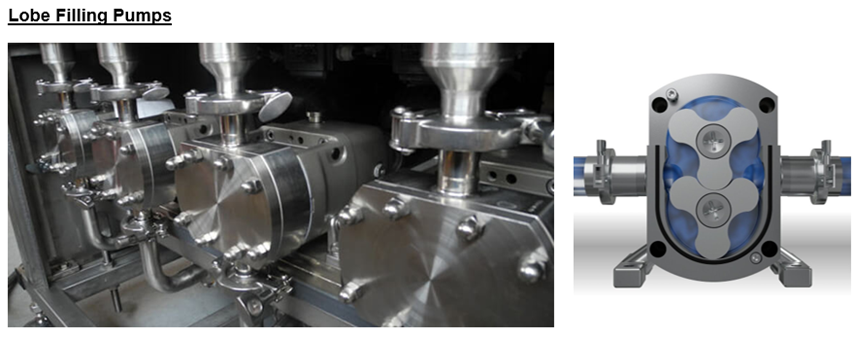

Full-automatic Linear Lobe Pump Filling Machine – 6 head

20L – 8BPM / 10L – 15BPM / 5L – 20BPH

The, Inline Rotary Lobe Pump Liquid Filler model SLA-RL was designed to deliver an accurate means for filling thin to very viscous products without overflowing or volume limitations. An individual servo motor coupled with a Lobe pump is mounted behind the machine frame and supplies product to each individual filling head. This allows for a large variety of container types to be filled, from 1L to 50L containers. Automatic Indexing allows bottles to enter and exit the fill area smoothly. An Panasonic PLC controlled and Panel View operator interface controls the independent nozzle pulse settings. Each filling head can be turned on or off and individually adjusted.

* Sanitary Rotary Lobe pump performs filling viscous and general product, pump head made from 304 stainless steel

* Each rotary pump is driven by an individual AC motor and controlled by torque control frequency inverter for high accuracy of liquid filling pump type: big pump 20L

* No change parts are required for different bottle size except a bottle neck clamping plate

* PLC combined with touch screen control panel

* Digital setting allows different filling volume adjustment easily

* Semi Diving type filling nozzle

* Filling nozzles leakage block cylinder

* Leakage colleting tray

* Filling nozzle made of SUS#304 with anti-dripping cylinder Filling base can be adjusted up and down

* 200 Liter stainless steel liquid tank (With Liquid level control signal, not including the feeding pump)

* No Bottle No Filling

* The parts contacting the liquid are SUS#304

* Mild steel painted machine frame with waste collecting pan

* Conveyor with chain and inverter

Model: INP-6FLP

Power: 380V/3ph, 50Hz

Filling nozzles number: 6 / Machine with 6sets Sanitary Rotary Lobe pump,

Product: Edible oil

Filling Volume: from 1L to 50L

Lobe Pump: ZBA-20 20L per 100 rotation,

Output Capacity: 20L – 8BPM / 10L – 15BPM / 5L – 20BPH

Pick & Place Linear Capper – CP114

Pictures for reference only

INPU-40 Automatic Chuck Capper, places and torques caps. Caps are individually picked up by the mechanical swing arm and moved to the capping head. The container then moves under the capping station as the cap is accurately placed and torqued onto the bottle threads. This machine is intended for production speeds of 20-35 per minute for bottles up to diameter 53mm. Components for larger bottles/caps will be quoted upon review of samples. Cap Feeding and Sorting Systems are sold separately for configuration purposes.

Technical parameters

Supply Voltage: 220v, 50/60hz 1 Phase

Power Consumption: 2.2kw

Air Pressure: 4-6kg

Dimension: 2000*1500*2000

Cap Size: customize

Speed: 20-35 cs/min

Self-Adhesive Labelling Machine – LBL558

The electronic label application system is designed to automatically apply a labels onto products from the side. The machine is mainly constructed from 304 Stainless steel for durability and corrosion resistance. Stainless-steel cabinet house all the electronics and form the base where all units are mounted to. Setup for the machine is done on a central rotating control panel that is accessible from both sides of the machine.

Stepper motors and drives are being used together with a Human Machine Interface to ensure ease of setup and highly accurate labelling.

| HDPE BLOWING MACHINES FOR 5L, 10L, 20L |

SCOPE OF OFFER

HDPE BLOWING MACHINES FOR 5L, 10L, 20L

Output for 2 lines: 5L-4pcs/minute. 10L-2pcs/minute. 20L-2pcs/minute.

Price List

| Qty | Price | Total | ||

| HDPE Blow moulding machine INP75BB | 2 set | |||

| Robot arm | 2 set | |||

| Down blow system | 2 set | |||

| Vacuum feeder | 2 set | |||

| 5L blowing mold | 2 set | |||

| 10L blowing mold | 2 set | |||

| 20L blowing mold | 2 set | |||

| Chiller 10HP | 1 set | |||

| 500kg mixer – hopper | 1 set | |||

| PC600 crusher | 1 set | |||

| Crushing and recycling barrel 200KG | 1 set | |||

| OPTIONAL – included in the price | ||||

| Screw air compressor 18.5KW + 1m³ gas storage tank | 1 set | |||

| Sub Total Equipment | ||||

| SERVICES | ||||

| F.A.T. (FACTORY ACCEPTANCE TEST) | Included | |||

| CIF DOUALA CAMEROON | ||||

| ASSEMBLY / TESTING / PERSONAL TRAINING | ||||

| Sub Total Services | ||||

| Sub Total | ||||

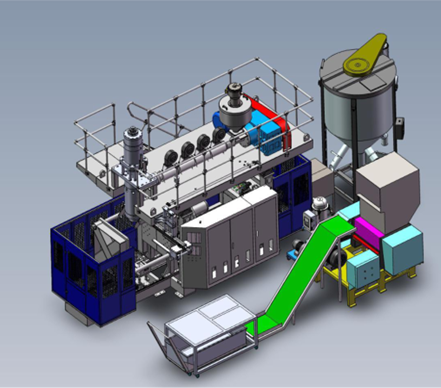

Automatic HDPE bottle blowing machine

OUTPUT FOR 1 MACHINE: 5L 2pcs/per minute | 10L 1.5 pcs/per minute | 20L 1pcs/per minute

PARAMETERS

| SPECIFICATIONS | UNITS | INP75BB |

| Max container capacity | L | PRODUCT COVERAGE 10-30L |

| Number of die heads | Set | 1 |

| Machine dimension (L*W*H) | M | 4.1*2.3*3.6 |

| Total weight | Ton | 9 |

| CLAMPING UNIT | ||

| Clamping force | KN | 176 |

| Platen opening stroke | mm | 250-700 |

| Platen size | mm | 720*600 |

| Max mold size (W*H) | mm | 440*650 |

| Mold thickness | mm | 250-350 |

| POWER | ||

| Max drive | KW | 30 |

| Total power | KW | 60 |

| Fan power for screw | KW | 0.4*3 |

| Air pressure | Mpa | 0.6 |

| Air consumption | M3/min | 0.4 |

| Average energy consumption | KW | 20 |

| EXTRDER UNIT | ||

| Screw diameter | mm | 75 |

| Screw L/D ratio | L/D | 25 |

| Plasticizing capacity | Kg/hour | 90 |

| Number of heating zone | Zone | 4 |

| Extruder heating power | KW | 20 |

| Extruder driving power | KW | 30 |

| DIE HEAD | ||

| Number of heating zone | Zone | 4 |

| Power of die heating | KW | 15 |

| Max die pin diameter | mm | 250 |

| The die head volume | L | 4(3KGHDPE) |

| Hydraulic system | ||

| Drive part | Servo motor+ pump | |

| Power and displacement | 18.5KW+63L/Min | |

| Wall thickness control hydraulic for MOOG | 4KW Independent oil pump | |

| INTEGRATED CONTROL SYSTEM | 10” touch screen + Mitsubishi PLC | Japan |

| 100 POINT PARISION CONTROL | MOOG | Japan |

| TEMPERATURE CONTROL MODULE | 7018 | Taiwan |

| SERVO VALVE & SERVO TRANSDUCER | AUTOS | Italy |

| INVERTER | Inovance | China |

| HYDRAULIC OIL SEAL | DZ | Taiwan |

| INTERMEDIATE RELAY | Schneider | China |

| PNEUMATIC VALVE | Airtac | China |

| HYDRAULIC VALVE | YUKEN | Taiwan |

| LOW VOLTAGE ELECTRONIC PARTS | Schneider | China |

| HYDRAULIC MOTOR & SCREW MOTOR | Siemens | CHINA |

| Extrusion system | Special design according to the processing performance of raw materials (high efficiency screw), material: 38CrMoAlA, nitriding treatment, hardness ≥800, brittleness ≤2 grade. Suitable for new materials, broken materials, recycled materials. Inverter + AC motor + hard gear reducer drive, |

| Die head system | Accumulator die head, single cylinder, central injection, vertical FIFO design, smooth flow path of die head; The shooting piston and cylinder block slide each other moving parts, using different materials and technology, to ensure smooth and reliable movement of parts. The molten material extruded from the extrusion system flows through the inner core assembly of the die head, and is divided into two parts, each side envelope, through the die head flow channel divide and form two peach-shaped sections. |

| Clamping system | Fixed opening and closing mechanism, diagonal double pull rod single cylinder center locking, pull rod across the template oblique arm guide sleeve, pull rod plated hard role processing, High hardness, more stable clamping, more uniform clamping force, template space, strength, no deformation, mold disassembly is convenient, Linear rolling guide, central cylinder locking mold, mold closing speed. |

| Multi-function blowing system | Optional blowing needle up and down, support material, sealing and other functions; According to customer or product requirements to improve production efficiency. |

| Machine shelf | With lifting function, hydraulic motor or motor drive. Increase the size of the transmission rod to ensure the transmission force, large lifting size, adapt to mold changes. |

| Hydraulic system | Hydraulic main system adopts servo system, proportional pressure, flow control, with oil pressure feedback, mold closing response speed, more accurate output,

More stable operation, high pressure, large torque, no pressure, flow loss, the system is more energy saving, long service life and so on. Hydraulic servo system adopts position, speed double closed-loop design, equipped with MOOG 100-point wall thickness controller, servo valve, control curve tracking more precision and other characteristics. |

| Electrical control system | Electric control system adopts Japan Mitsubishi PLC for the whole machine action program control; WEINVIEW LCD display and touch screen for communication, parameter setting, modification and screen display; Each process parameter can be set and modified directly, and has a more perfect fault diagnosis function, screen operation is intuitive, convenient. |

| Safety device | Safety electric eye double protection, with large safety distance, more accurate reflection characteristics. |