Description

- 250 ml @16,000 bph

- 300 ml @16,000 bph

INPAKT

Sales Person: Alexi Christie

Tel: +27 81 373 9154

Email: alexi@inpaktgroup.co.za

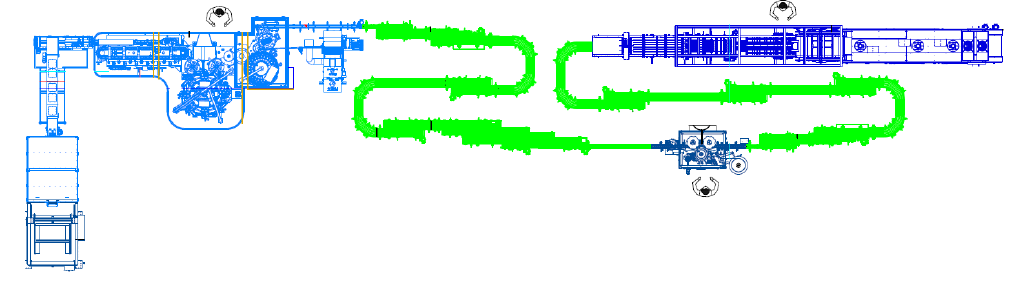

1 – LINE DESIGN

Design & Line Parameters

| Basic format – Product | 0.25 L and 0.30 L – CSD |

| Leading Machine | Er-miraBLC 8 |

| Nominal line speed* | 16.000 bph |

| Line efficiency** | 90% |

| Bottle | Capacity | Design line speed | Pallet Type |

| Second format | 0.5 L | 16,000 bph

3×4 film only 6×4 film only |

1200 x 800 |

| Basic format | 1.5 L | 10,000 bph

3×2 film only

|

1200 x 800 |

The mentioned values are for information only and is subject to change

The presented above values are indicative and subject to confirmation after receiving the definitive drawing of the container, the definitive weight of the preforms.

The final position of equipment, chiller, compressor shall be determined according to the customer warehouse measurement and his building limitation

Conveyors and line design is subject to change according to final layout . Any modification requested by Purchaser or additional conveyors will be priced.

2 – ENVIROMENTAL CONDITIONS

| Description Criteria | Standard Value | |

| Outdoor temperature | Min (°C) | +5 |

| Max (°C) | +40 | |

| Indoor temperature | Min (°C) | 15 |

| Max (°C) | 30 | |

| Altitude | Max ( above sea level) | 300 |

| humidity | Min (%) | 30 min 30% – max 70%. |

| Max (%) | 90 | |

| Chiller location | In Room | |

| Electrical Power | Voltage (V) | 400 |

| Tolerance (%) | + /- 10 | |

| Frequency (Hz) | 50 | |

| Distribution System | ||

| Phases | 3 PH | |

3 – CONTAINER FEATURES

| Container name | Format 1 | Format 2 |

| Container | ||

| Product | CSD | CSD |

| Container | 0.5 | 2 |

| Material | PCO 1881 | PCO 1881 |

| Drawing | TBD | TBD |

| Preform drawing | TBD | TBD |

| Neck Type | PCO | PCO |

| Shape | Round (stright /wavey / standard ribs ) | Round (stright /wavey / standard ribs) |

| Diameter (mm) | Ø=68mm | Ø=88mm |

| Bottom type | Flat | Flat |

| Material weight (g) | TBD | TBD |

| Filling Tempreature (°C) | 7-15 | 7-15 |

| Cap | ||

| Drawing | TBD | TBD |

| Type | Screw Flat Cap | Screw Flat Cap |

| Neck finish typ | PCO 1881 | PCO 1881 |

| Material | Plastic | Plastic |

| Label | ||

| Drawing | TBD | TBD |

| Material | OPP | OPP |

| Label type | Wrap around – roll fed | Wraparound – roll fed |

| Packaging | ||

| Type | Only film | Only film |

| Configuration | 3×4 | 3×4 |

| Pallet type | 1200×800 | 1200×800 |

4 – EQUIPMENT TECHNICAL DESCRIPTION

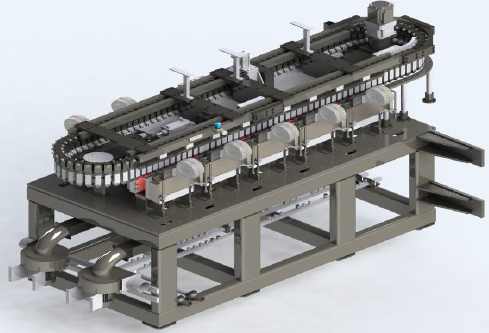

Rotary INC8 Blowing Filling Capping

MODEL 8-INP44-8

8 cavity rotary stretch-blow moulder

44 electro-pneumatic filling valve rotary

8 head rotary capper, for screw caps

Picture is only for clarification purposes.

General Description

Integrated system and Perfect combination of stretch blow moulding, filling and capping in a single block

Stretch blowing unit is equipped with a heating module and high efficiency reflective panels to ensure uniform heat distribution on the preform.

filling area is entirely made of stainless steel and glass.

Neck handling system, and transmission system by wheels.

Preform heating (heating oven)

Picture is only for Clarification purposes.

- Consisting of a horizontal linear heating module which ensure very precise heating process with low electrical consumption

- Optimize ventilation operations

- Infrared lamps grouped in various sections and individually controlled.

- Dedusting system

- Detect and eject incorrectly loaded preforms, which located before the oven inlet

- Accurate preform transmission from the oven to the mold

- A collecting case (bin) for ejected preforms, can able of emptying during machine operation

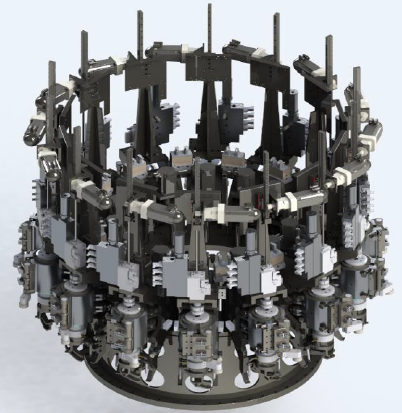

Blow station

Picture is only for Clarification purposes.

- The machine‘s Rigid body construction provides stable operation and longer life

- Elimination of conveyors between the blow-moulder and the filler

- The direct transfer of the bottles from the stretch blow moulder to the filler and capper is provided .

- Easy access to the machine components , cleaning easier

- Reduce noise , no vibration , quieter bloc

- Dedicated to all bottles belongs to the range 0,2 lt -2 lt

- Wide opening doors for easy access to the machine components for maintenance and quick-changeover

- Central rotating wheel for blowing station

- NO Cam system commanding mold unit , Fully PLC controlled ,Fully electric

- Patented opening-closing system for mould carriers controlled by servo

- Servo controlled stretching system

- Auto-locking system for mould

- Quick-locking system for mould carriers

- Synchronously closed + lock system

- Aluminum mould ‘s holders made of iron

- Fast with no vibration

- Controlled pneumatic mold compensation using solenoid valves

- Air recycling system

- Tracking system for each cavity

- Solenoid assembly for air distribution in the blowing mold with low consumption

- Lubrication; An automatic pump to grease all the points

- user friendly interface navigation system for machine operation, maintenance, mechanical setting and process parameter

- Industrial PC system is electronically controlled.

- Industrial PC has Ethernet port, so the process has the ability to intervene immediately to the problems on the internet

- All process parameters can be set via the Industrial PC

- A temperature control system of the oven

- Pre-blowing process apply by electronic servo-controlled stretching unit

- Electronic servo controlled clamp and preform transfer group provide transfer process without wastage

- Oven wheel system which has48 mm pitch achieve 10% additional power saving

- Independent servo control implements on the transfer wheels units of

- Perform & bottles to provide quick adjustment via its easily PC

- Fully electrically , No Cam system commanding mould Unit

- Process monitoring system is implement for each cavity of the mold depending on the pressure -time graphical diagram

- Advanced HMI electrical control

- Cooling system for mold

- Air recovery system provides up to 25% saving

- An ejection system for defective bottles

- A machine emergency stop disk brake

- A manual drive for machine adjustment and maintenance

- Quick format change over

- Reduction of format change-overtimes, and extremely less maintenance.

Control console

- Consisting of navigation system for machine operation, maintenance, mechanical setting and process parameter set-up

- Machine operator intervention and it ‘s follow-up is comfortable through 15 “” color TFT touchscreen

- Multi languages.

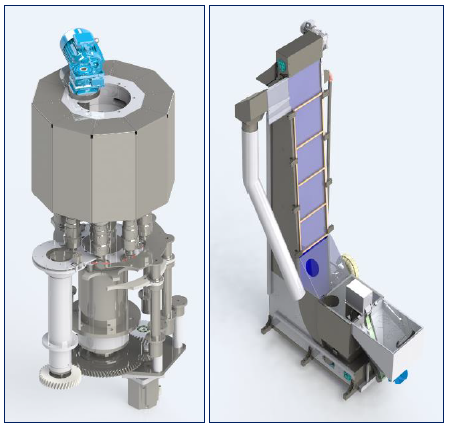

Octabin Tilting Unit

| Characteristics Type | |

| Installed power | 240 KW |

| Consumption | 83 KW |

| Voltage | 220 – 380 V 3 phase 50 Hz Variable Frequency Driver |

| Machine Control | PLC |

| Low Pressure air consumption | 2 m³/minute- 8 Bar |

| High pressure air consumption | 23 m³/ minute -30 Bar |

| Cooling Water | 110.000 kcal/hour 5-7˚C |

| Cooling Water Pump | 60.000lt/hour ∆P=3 Bar. ( ∆P=Pin-Pout) |

| Characteristics Type | |

| Servo Motor

|

BOSCH REXROTH – KOLLMORGEN

|

| Drivers | BOSCH REXROTH – KOLLMORGEN – OMRON

|

| PLC | BOSCH REXROTH – KOLLMORGEN – OMRON |

| Bearings | ROLLEX – FAG – SKF – ORS |

| 40 BAR Valves

|

INPAKT |

| Pneumatic | SMC – FESTO – MAC |

| Gear Box | LİMİNG – APEX |

| Mold Material | ALÜMİNYUM |

| Electrical component | WEIDMULLER – EATON – OMRON

|

| Sensör | TURCK WENGLOR – Sick

|

| Machine frame | SS |

Filling station

Is a fully automatic rotary filling/capping bloc, it is integrated with blow moulding machine which eliminate rinsing and air conveyor.

Picture is only for Clarification purposes.

- Completely automatic rotary filler specifically designed and manufactured for high speed lines

- Prevent overflow

- Very precise

- Easy cleaning (internal, external)

- Base frame in AISI 304 stainless steel and self-draining slopes to avoid water retention

- All the surfaces which contact with the product is AISI316 stainless steel

- No bottle –no filling system

- Hepa filter with fully enclosed cover

- Individually controlled from the operator panel

- A sensor detects the presence of the bottle before entering the filler

- Quick format changeover

- Stainless steel necking star for bottle transfer

- Bottle neck handling

- Star-wheels for bottle transfer

- Automatically speed controlled by the PLC

- Pre-arranged for cip with dummy bottles

- Manual dummy bottles

- Guaranteed hygiene: over pressure with Class 10,000 filtered air on the transfer table prevents contamination of the outside of the bottle

Any other configuration can be separately quoted as options.

Electro pneumatic controlled isobaric filling

- The container and the filling head ll be in contact.

- To create pressure in the bottle and equalized the condition of tank pressure.

- Faster and efficient gas release.

- All the operating phases (filling, gas release, etc.) are run automatically.

- Very precise gas release phase.

- Reduces the risk of foaming and liquid overflowing.

| Characteristics Type | |

| valve | |

| Filling principle | Electro pneumatic controlled isobaric filling

|

| Container handling | By Neck |

| Container transfer | starwheel |

| Construction | |

| Frame | AISI304 stainless steel welded structure |

| Draining | Self draining sloped surface |

| Tank | AISI316L stainless steel |

| Metal parts in contact with product | AISI316L stainless steel |

| Plastic parts in contact with product | Food gradable |

| Electric cabinet | |

| cabinet | stainless steel |

| Characteristics Type | |

| Voltage | 220 – 380 V 3 phase 50 Hz Variable Frequency Driver |

| Machine Control | PLC |

| Speed Control By | PLC |

| Characteristics Type | |

| Motor | GAMAK – ELKMOTOR – BOSCH REXROTH KOLLMORGEN – OMRON |

| valve | INPAKT |

| Reductor | YILMAZ (TURKEY) |

| Gear Box | LİMİNG – APEX |

| AUTOMATION AND CONTROL SYSTEM | |

| PLC | BOSCH REXROTH – KOLLMORGEN – OMRON |

| Pneumatics | SMC – FESTO – MAC |

| Electrical components | Weidmüller – Eaton -Omron

|

| Sensors | Turck Wenglor – Sick

|

| Filter | HEPA-14 |

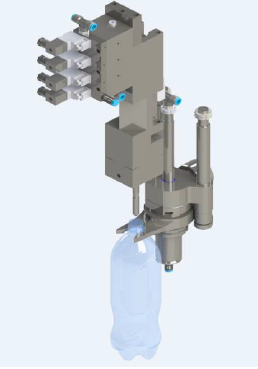

CAPPING MODULE ( CAPPER )

Picture is only for Clarification purposes.

For one specific type and format of cap, Any other configuration and its equipment are separate and quoted as options

Cap elevating and orienting system

components & operation:

- Cap feeding system (water-fall feeding system)

- Cap hopper

- Elevating

- Orienting system

- Discharge

- Cap chute

- Capping heads are equipped with chucks , with magnetic clutch to adjust the torque

- No bottle – no cap system

The caps are transferred to a pick and place device through channel (chute );The capping head moves downward to the bottle and applies the cap.

- Neck handling – for PET

- Stainless steel support to hold the container during capp

- Bottle presence sensor

- Caps feeding system placed outside the machine

- A Pick and Place device to transfer caps to the closing head

- No bottle – no cap mechanism

- Caps are manually loaded into the hopper ( top cover )

- Basically for one specific type and format of cap

- For any other configuration and its equipment are separate and quoted as options

- UV lamps provided for sterilization caps.

Handling

- Container handling by the neck

- Container released on an outfeed conveyor with adjustable height system

| Characteristics Type | |

| Frame | AISI 304 Stainless steel |

| Capping heads material | AISI 304 Stainless steel |

| Hopper | AISI 304 Stainless steel |

| Pick and Place star-wheel material | AISI 304 Stainless steel |

Ancillary equipment capacity depending on the country specifications (altitude, temperature, humidity etc.)

Auxiliary parts are not included to the offer.

ANCILLARY EQUIPMENT

High and Low-Pressure Air Systems

Chiller

The final position for the chiller and HP compressor shall be determined according to site measurements

(max 10 m- 15m from blow molder)

Quality of Cooling Water and Distribution Circuits:

| Parameters | Value |

| Ph | 6.5 < pH < 8 |

| TH (Total Hardness)* | TH < 5 °F – 50 mg/L TH < 35 °F if chemical treatment) |

| TA (Simple Alkalinity) | TA < 40 °F – 400 mg/L |

| TAC (Total Alkalinity) | TA < 40 °F – 400 mg/L |

| Ca2+ | mg/L (the lowest possible) |

| Mg2+ | mg/L (the lowest possible) |

| Fe2+ | Fe2+ < 3 mg/L |

| Mn2+ | mg/L |

| CO3H – (Bicarbonates) | mg/L |

| Cl (Chloride) | Cl < 2.000 mg/L (the lowest possible) |

| SO42– (Sulfates) | SO4 < 250 mg/L |

| MEST (Total Suspended Solids) | MEST < 100 mg/L |

| FI (Clogging Capacity)** | FI < 3 |

| Organic Fraction | mg/L |

| Mineral Fraction | mg/L |

| Residue heat 110 °C | mg/L |

Minimum volume of water required for analysis=1.5 L

Characteristics

The water circuit must be a closed circuit.

Fit an active 20 μm nominal filter (50 μm absolute) at the machine in let in order to project the machine against their lease of solid particles from the piping or accidental pollution from other machines on the line.

Quality of Air

The air provided by the buyer will comply with quality as below :

| Quality of Air | ||||

| Residual Dust | Residual Water | Residual Oil | ||

| ɥm | mg/m3 | DTP[C] | g/m3 | mg/m3 |

| 0,1 | 0,1 | -70 | 0,003 | 0,01 |

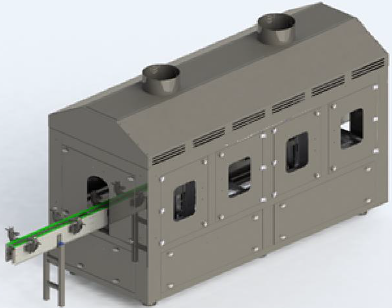

BOTTLE DRYER

Picture is only for Clarification purposes.

For PET and glass bottles

- Dryer module

- Blow-drying of containers

- Low-maintenance

Configuration according to:

- Bottle drawings

- Production speeds

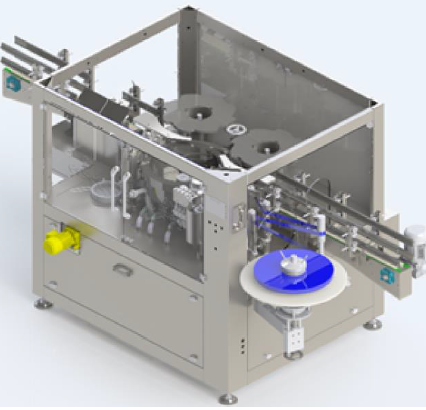

LINEAR OPP LABELLER – SOLM

Picture is only for illustration purposes and not conditionally matching supplied machine.

Linear labeling machine is able to apply wrap around paper label on the body of PET bottles via hot glue technology.

DESCRIPTION

Type SOLM

Automatic Linear roll-fed hot glue labeling machine for applying complete wrap-around roll-fed labels to plastic containers

- Linear design for easier handling

- Compact design enables the operator to control all labelling processes

- Simple change-over and maintenance procedures

- Less adjustment

- Easy settings of the labels transfer drum parameters

- Easy settings of the labels cutting parameters

- Adjustments via HMI

- Roll-stand

- Feed roller

- Cutting module

- Integrated HMI for all operations, including labels registration/cutting

- Transfer vacuum drum

- Hot melt glue application module.

| Characteristics Type | |

| PLC | BOSCH REXROTH – KOLLMORGEN – OMRON |

| SERVO | BOSCH REXROTH – KOLLMORGEN – OMRON |

| Electrical component | WEIDMULLER – EATON – OMRON

Eaton Omron |

| Sensors | TURCK WENGLOR – SICK

|

| PNEUMATIC | SMC – FESTO – MAC |

| REDECTOR | LİMİNG – APEX |

| BEARING | FAG – SKF – ORS |

| Voltage | 220 – 380 V 3 phase 50 Hz |

| Control Voltage | 24 V |

| Istallation Power | 15 KW |

| Speed Control | SERVO |

| Machine Control | PLC |

| Label Type | O.P.P., P.E. |

| Label Feeding Application | From rolls |

| Glue Type | Hot Melt |

| Ambient Temperature | 5-35 ºC |

Shrink Wrapping Machine Overlap (One Way)

Picture is only for illustration purposes and not conditionally matching supplied machine.

Overlap System Fully Automatic Shrink Packaging Machine with PLC control system, LCD touch screen, 6 servo motors and 8 different programs. There is a 6-channel bottle dispensing unit in the feeding unit of the machine. Horizontal and vertical products coming from the speed-controlled feeding conveyor are grouped in desired quantities. The automatically incoming grouped products are wrapped in automatically fed (PE) polyethylene foils with the help of conveyor belts and the process is carried out with the latest technology overlap system.

Products wrapped in polyethylene foils are fed into the Shrink tunnel with a speed-controlled conveyor and shrinked.

PREMIX SENS MIX

Picture is only for Clarification purposes.

Fully automatic blending and carbonating

System complete system for preparing carbonated soft drinks

mixing a syrup with deaerated water and then carbonation

Process phases

- Water deaeration

- Dosage and mixing of the water & syrup

- Carbonation

Plc control

Advanced flow meter technology for mixing and carbonation

Water deaeration by vacuum pump

Complete product receipt management

Correction option of syrup brix function

Technical Data :

Designed for 7, 10 , 15 and 30 m³/h

Maximum Brix: 30% (Brix: Syrup or solid solution ratio in the final product)

Water inlet temp 15 c

Syrup inlet temp 25 c

max carbonation temp 12-15 c

Co2 content 8.8 – 11 g/l

Chiller not included

Automatic classic Palletizing & Stretch Wrapping Machine

Picture is only for illustration purposes and not conditionally matching supplied machine.

| Technical Details | |

| Model | EP 100 |

| Pallet dimensions | Euro pallets 800 x 1200 mm

Local pallets 1000 x 1200 mm |

| Capacity | 2000 Packet/ hour, 24.000 – 34.000 bottle / hour |

| Full pallet height | 0,5 lt – 8 fold – 1870 mm |

| Pallet height | 150 mm |

| Voltage | 220 – 380 V 3 phase 50 Hz |

| Control Voltage | 24 V |

| Control | SERVO,PLC |

| Power Consumption | 6 kW |

| Body Weight | 5.000 kg. |

| Body Dimensions | 7800 mm x 8650 mm x 4770 mm |

| Body Material | St42- 37 Fe, DTM 7025** paint |

Stretch Wrapping Machine

Picture is only for illustration purposes and not conditionally matching supplied machine.

- High performance rotating arm machine for wrapping pallets with stretch film

- Reliable, robust construction

- Flexibility on the production, products and layout

- Rotating arm pallet wrapper

- Driven rollers electronically controlled

- Photocell detection

- Base frame

- User Interface

- Pallet lifting system

- Stretch finishing, cutting, gluing system

- Quick stretch changing system

- Safety control system

- Safety barriers

| Characteristics Type | |

| Servo Motor

|

BOSCH REXROTH – KOLLMORGEN

|

| Drivers | BOSCH REXROTH – KOLLMORGEN – OMRON

|

| PLC | BOSCH REXROTH – KOLLMORGEN – OMRON |

| Bearings | FAG – SKF – ORS |

| Pneumatic | SMC – FESTO |

| Gear Box | LİMİNG – APEX |

| Electrical component | WEIDMULLER – EATON – OMRON

|

| Sensör | TURCK WENGLOR – Sick

|

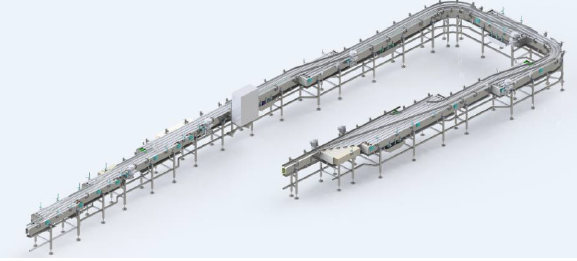

CONVEYORS

Set of stainless steel bottle conveyor as per layout

Frame, supports, legs and components made of stainless steel AISI 304

wide range of belts , curved Frame , Transfer Frame

| Characteristics Type | |

| Belt

|

REXNORD – KAZİAN |

| Gear | YILMAZ REDÜKTÖR |

| Invertor

|

OMRON – ABB |

| Bearings | FAG – SKF – ORS |

EQUIPMENT LIST & PRICES

| 1 | ROTARY STRECH BLOW MOULDING – FILLING – CAPPING

Rotary Stretch 8 |

||

| Qt | |||

| Rotary Stretch-blow moulding INC 8

Rotary 8-INP44-8 Heating module : linear over with infrared heating technology Hot air extraction : Oven exhaust hood

Preform Feeder (orienter ): provides the stretch blow moulder with preforms and can be adjusted to the preform sizes. Pet preform dumper (tilter) Pet preform elevator feed rail. Platform with stairs

High-pressure compressed air filtration : using a 0.01 µm fine filter. Air recovery system: Air recycling system recovering a part of the blowing air and reusing this air for the preblow

Automatic lubrication (food gradable grease) system including pump and plastic pipes

Protection cover with air filtration unit

Faulty containers are rejected within the machine Fualty heated preform are rejected within the machine Mould change: manual mould quick change without tools For base change there is pneumatic button (change over time 60 min )

|

1 | INCLUDED | |

| Main electrical cabinet in AISI304

Main electrical cabinet air conditioning system internal lighting

|

1 | INCLUDED | |

| HMI : ENGLISH | 1 | INCLUDED | |

| Aluminium moulds (0.5 lt ) | 1 | INCLUDED | |

| Aluminium moulds (1,5 lt ) | INCLUDED | ||

| 24 V UPS for Automation group | 1 | INCLUDED | |

| Automatic CSD Filling-Capping

Electro pneumatic valve Control System

Simple structure and economical in service and maintenance Hygienic Design Product tank in stainless steel AISI 316 Parts in continuous contact with product (tank, filling valves, piping) in S/S AISI 316 No bottle No filling Fill level determination : vent tube Full automatic operation plc controlled Bottle stopping mechanism Equipped with photocells in inlet and out let of the machine Automatic product feed equipped with sensor to control the level in the product tank Drain channels meet in one point Rotary Capper Screw capper 14 head Caps feeder (water-fall feeding ) Cap elevator Cap Sorter AISI304 SS Cap Channel AISI304 SS Cap ejection UV lamps for Cap feeding system No bottle No capping

Manual operated CIP dummy bottles (CIP up to 90 degree) Hepa filter for positive pressure Lubrication system (top capper , bearings , filler , rinser ) manually operated. Pneumatic 5 micron filter 24 V UPS Industrial AC : electrical cabinet air conditioning system

|

1 | INCLUDED | |

| 2 | PREMIX 20 TON | ||

| Fully automatic Blending and carbonating

three modules deaeration, dosing and carbonation different sizes with variable outputs from 7 ton to 20 ton

electronic flow control valves

· syrup / water mixing ratio 1/3 up to 1/5 · brix accuracy : 0.05 – 0.03 brix · CO2 mixing ratio : 8.8 lt – 11 gr / lt · Max carbonation temp 12-15 c

The carbonation temperature of 15 C is for a maximum of 8.8 gr/L, the mixing ratio should be specified by the customer since higher chiller will be needed for higher ratio CO2 mixture.

Deaeration horizontal deaeration tank the water feed is done by set of nozzles and the deaeration using vacuum process for the purpose

Dosing module Buffer tank equipped with level sensor Top product quality due to product homogenisation by 2 static mixer (2 stage )with flow meter and proportional valves

Carbonation module : Venturi mixer for efficient and consistent carbonation

24 V UPS Industrial AC : electrical cabinet air conditioning system |

1 | INCLUDED | |

| 3 | OPP OLM-SRV LABELLER | ||

| Linear Roll Fed labelling for cylindrical container

Roll-stand, Feed roller, Cutting module Transfer vacuum drum Hot melt glue application module |

1 | INCLUDED | |

| 3 | BOTTLE DRYER | 4 | |

| FULL BOTTLES DRYERS to remove residual from the outsides surfaces of the containers with air | INCLUDED | ||