Description

BUDGET OFFER:

20000 cans per hour (340ml) CSD canning

CLIENT SPECIFICATIONS

We take pleasure in offering the following equipment:

A. CSD CANNING LINE

This is a budget offer which is subject to receiving all the product drawings, technical specifications, confirmation of label film for shrink-wrap and final product technical details.

COMMERCIAL OFFER

20000 CANS PER HOUR (340ML) CSD CANNING

| No | Name | Model | Output | Qty. | Unit price | Total price | Details |

| A: BEVERAGE PROCESSING & MIXING SYSTEM, 8 TON/HOUR | |||||||

| 1 | Cooling system | LSJ-90S | 90HP | 1 set | ※Water cooling type

※USA copeland compressor |

||

| CO2 Filter | CO-2 | 8T/H | 1 set | ||||

| 2 | Carbonator | QHS-8000 | 8T/H | 1 set | ※Siemens PLC+HMI

※Mixing ratio:3.8-4.2, with proportional valve ※CO2 filtering and pressure regulating system ※CO2 pressure balancing system ※With vacuuming system |

||

| 3 | Cooling tower | LCT | 80T | 1pc | ※For cooling the juice from 130 Degc to 90 Degc | ||

| 4 | CIP system | CIP2000LS | 1000L | 1pc | ※Material: SUS304 / thickness:3mm

Overall size: Dia600*1200mm |

||

| 4.1 | CIP back pump | YA10T/24 | 10000L | 1pc | ※Capacity:10000liter / Lift:24m | ||

| 5 | Steam generator | GL | 2000KG/H | 1pc | ※Diesel type

※Italian Baltur burner |

||

| 6 | Pipe works | ※On-site engineering welding

※Designed as shown in the drawing ※All Valves has to be butterfly valves, Flanged gasket fittings, included in chilled water, CIP station to Machines, treatment to syrup prep to carbonator to Filling Seaming. This has to include the CIP and Return Line as well. ※RO water pipe works ※Cooling water pipeworks ※Steam pipeworks ※Low pressure compressed air pipe works ※Note: The total length and quantity of the pipework are calculated based on the drawing for this project. |

|||||

| B: FILLING & PACKING – 20000CPH | |||||||

| 7 | Automatic depalletizer | XD-4000 | 20000CPH | 1 set | ※SUS304 as the structure | ||

| Inline can rinser | 20000CPH | 1 set | ※Can inverter

※Pumps and pipe works |

||||

| 8 | Aluminum can filling sealing machine | GD30-4 | 20000CPH | 1 set | ※Siemens PLC+HMI (on the control cabinet)

※Independent control cabinet ※Siemens VFD speed regulation ※Autonics Sensors ※SKF bearing ※IGUS sliding sleeve ※Schneider electric components ※SUS304, 3mm supplied by POSCO, S.Korea ※30 filling heads,Semi-automatic electronic filling valves ※4 sealing heads |

||

| 8.1 | Change part for different diameter can with the same can end size | 1 set | ※The Lid must be the same size for all size cans | ||||

| 9 | Can warmer | WPJ | 20000CPH | 1 set | ※18000*1500mm

※Siemens PLC+HMI ※Siemens low voltage electric components ※Four temperature regulation zone ※UK Spirax Sarco Steam control system |

||

| 10 | Drying machine | CGJ | 20000CPH | 1 set | ※with two 7.5 kW power fans

※Dust proof |

||

| 11 | Liquid level tester | ZJZ-200 | 20000CPH | 1set | ※Real-time tracking sensor

※Non-contact monitoring |

||

| 12 | Can

pressure tester |

NYJ-200 | 20000CPH | 1set | ※Nitrogen type

※Siemens PLC ※Real-time tracking sensor |

||

| 13 | Can Inverter | 20000CPH | 1 set | ※For 340ml can | |||

| Can inverter | 20000CPH | 1 set | ※For 500ml can | ||||

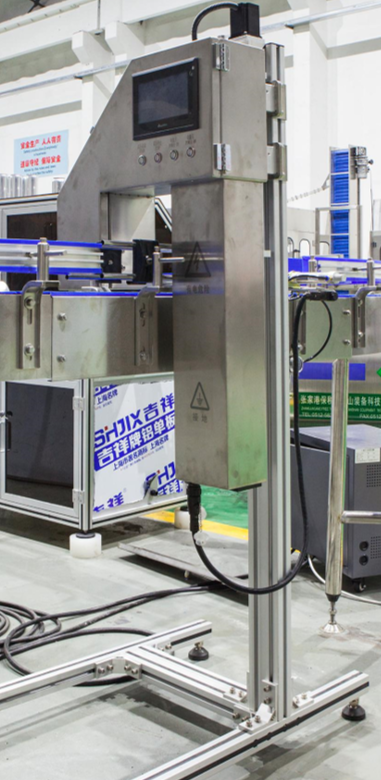

| 14 | Ink printer | VJ1240 | 20000CPH | 1 set | ※Supplied by American Videojet company | ||

| 15 | High speed Semi-auto Shrink wrapper | YCBS30 | 25packs per minute | 1set | ※B&R PLC+HMI

※B&R Servo motor ※Schneider VFD ※LEUZE sensor ※With colored film function |

||

| 16 | Flat conveyor with motors | SC-1 | 20000CPH | 246m | ※SUS304, supplied by POSCO, Korea

※AS per the finalized layout ※Water collecting tray ※SUS304 cable sorting cage ※SUS304 Air pipe sorting ※VFD controlled motors |

||

| Conveying motors | 16sets | ||||||

| 90 degree turn | 16sets | ||||||

| 17 | Low pressure air compressing system | DY-2 | 1.8 m3/min | 1 set | ※Oil free type

※10 Bar ※Including air filter and dryer ※Supply the compressed air to packaging line |

||

BEVERAGE PROCESSING & MIXING SYSTEM, 6 TON/HOUR

-

WATER SOURCE PUMP WATER CHILLER

Technical parameters:

| Model | LSJ-90S | ||

| Refrigerating capacity | 216KW | ||

| 199520KCal/hr | |||

| Power supply | 3 phase 380V±10%:50Hz±2% | ||

|

Compressor |

Input power | 60Kw | |

| type | Totally closed scroll compressor | ||

| Quantity | Set | 6 | |

| Cooling water | Input temperature | ℃ | 30 |

| Output temperature | ℃ | 35 | |

| Flow | m3/h | 38 | |

| Connector spc | mm | DN80 | |

| Chilled water | Input temperature | ℃ | 2 |

| Output temperature | ℃ | -3 | |

| Flow | m3/h | 15 | |

| Connector spc | mm | DN50 | |

| Chilled water pump | Model | Vertical type pipe water pump | |

| Power | Kw | 5.5 | |

| Head | M | 31 | |

| Overall size | Length | mm | 3300 |

| Width | mm | 1300 | |

| Height | mm | 1700 | |

| Weight | kg | 2200 | |

Main components:

| S.N. | Name | Brand |

| 1 | Compressor | Copeland (USA) |

| 2 | Condenser | Imported efficient heat exchanger radiator fan with expanded connection of copper pipe& aluminium foil |

| 3 | Evaporimeter | Stainless steel efficient shell and tube heat exchanger |

| 4 | Expansion valve | Alco (USA) |

| 5 | Filter | Alco (USA) |

| 6 | Solenoid valve | Alco (USA) |

| 7 | Pump | Nanfang (top supplier in China) |

| 8 | Freeze-proofing switch | Kaobo (Shanghai) |

| 9 | Pressure controller | FENSHEN (Shanghai) |

| 10 | Water pressure gauge | CK (Taiwan) |

| 11 | High-low pressure gage | SK (Taiwan) |

| 12 | AC contactor | Schneider (France) |

| 13 | Thermorelay | Schneider (France) |

| 14 | Temperature control | Microcomputer LCD (AT, ST) |

| 15 | Structure | Unitary box type |

| 16 | Surface treatment | Sraying plastics |

| 17 | Tank type | Stainless steel heat preservation |

| 18 | Outlet water temperature | -2℃ |

| 19 | Regrigerating fluid | R22 |

| 20 | Protector | Compressor overload protection/ high-low pressure protection/ water break, shortage protection/ phase sequence protection/ pump overload protection/ air fan overload protection |

| 21 | Regrigerating medium | 25% ethylene gycol solution |

-

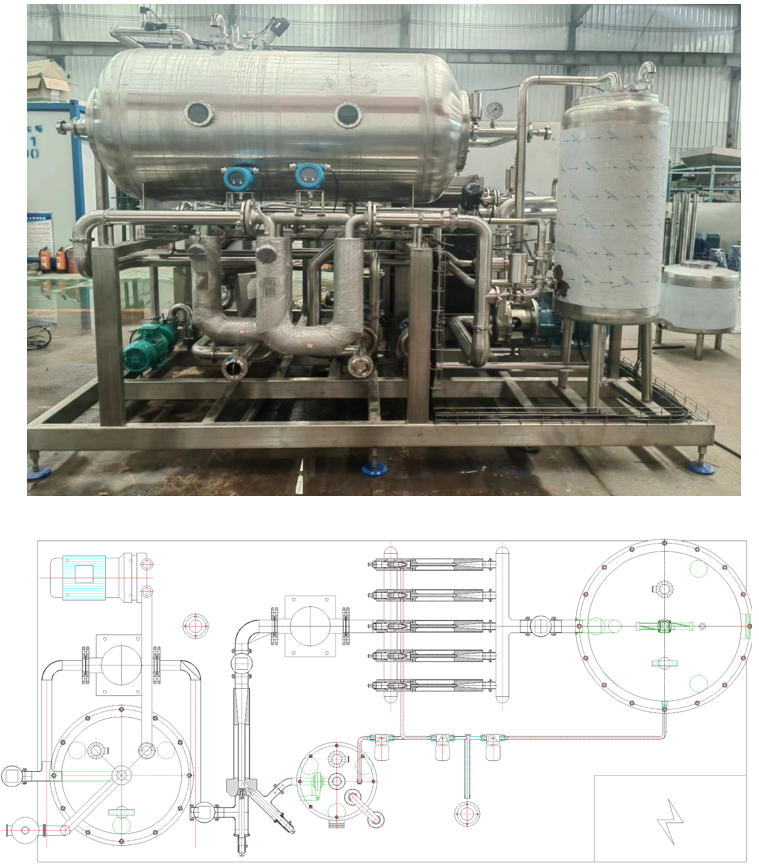

BEVERAGE CARBONATING MACHINE

The QHS-8000 Soda Mixer represents an automated apparatus meticulously crafted for the efficient manufacturing of diverse carbonated beverages. Setting itself apart from domestically produced counterparts, this equipment boasts comprehensive functionalities, precise mixing capabilities, user-friendly adjustability, and compliance with sanitary standards. Its innovative and rational design incorporates a closed system, ensuring compatibility with cleaning and disinfection protocols. The production of carbonated beverages is seamlessly executed with the flexibility to easily fine-tune production capacity and achieve optimal syrup ratios. Moreover, the integration of electrical control and other components endows it with features such as high automation, synchronized operation, continuous production, excellent mixing outcomes, and substantial production capacity.

Working principle:

The QHS-3000 automatic injecting gas-water mixer mainly consists of a vacuum section, a batching section and a gas-liquid mixing section.

- Vacuum section

The vacuum section consists of a closed circuit of the feed water inlet port by means of a solenoid valve, an air chamber, a vacuum pump and a vacuum tank equipped with a sprayer and a level controller.

- Matching section

The adjustment section consists of a ration pump, a slurry inlet line with a solenoid valve, and a syrup tank with a level controller. It consists of a syrup throttle valve and a venturi device. There are two adjustment handles with indicators on the venturi device. The size of the opening of the de-aerated water and the sugar liquid outlet is shown, respectively. A certain amount of opening also reflects a certain ratio. For the amount of sugar required for a particular beverage, you can change the size of the opening by turning the sugar adjustment handle.

- Gas-liquid mixing section

The gas-liquid mixing section consists of a mixing pump, a CO2 inlet line with a pressure regulating device, a gas-liquid mixed venturi device, a soda storage tank with a level controller, and a soda water output line with a safety valve.

Technical parameters:

| Model: | QHS-8000 |

| Capacity: | 8000 L/H |

| Mixing ratio(water: sugar): | 3:1—6:1 |

| Mixing precision: | ≤2% |

| Content of the CO2: | ≥4.0 times |

| CO2 supplying pressure: | 1-1.3 MPa |

| Heat exchanging area: | 3 m² |

| CO2 consumption: | 3 m³/h |

| CO2 purity: | ≥99.9% |

| Compressed air consumption: | 6.5 m³/h |

| Compressed air supply pressure: | 0.6-1 MPa |

| Refrigerant: | Ethylene glycol solution |

| Refrigerant temperature: | -2 ℃ |

| Mixing temperature: | 25 ℃ |

| Pressure at purified water inlet: | 0.3-0.4 MPa |

| Pressure at syrup inlet: | 0.3-0.4 MPa |

| Temperature at syrup inlet: | ≤25 ℃ |

| Temperature at beverage outlet: | 1-2 ℃ |

| Pressure at beverage outlet: | ≤0.65 Mpa |

| Power: | 10 kW |

| Dimension: | 3700*2200*2600 mm |

| Weight: | 1850 Kg |

Electric Components

| Items | Brand |

| VFD | Siemens, Germany |

| Low voltage electric components | Schneider, France |

| HMI | Siemens, Germany |

| PLC |

-

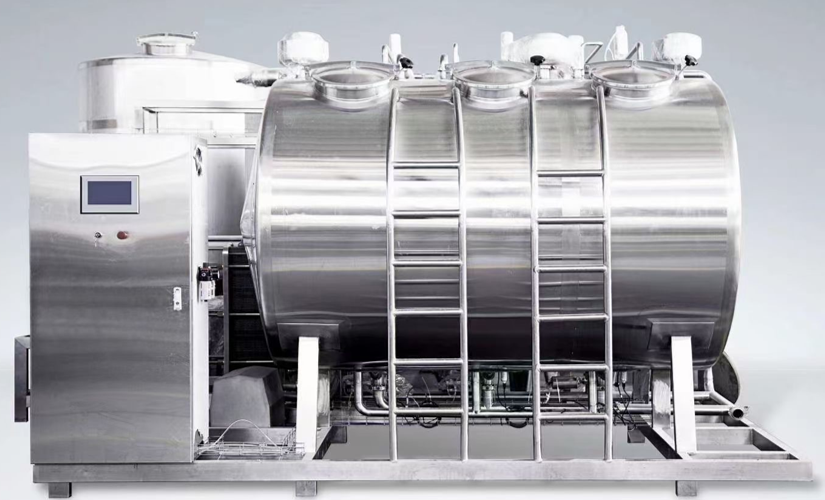

STEAM TYPE CIP CLEANING SYSTEM

Technical parameters:

| Model: | CIP2000LS | |

| Alkali tank volume: | 2000 L | |

| Acid tank volume: | 2000 L | |

| Hot water tank volume: | 2000 L | |

| Material of tanks: | SUS 304 | |

| Sanitary pump: | Water flow: | 15 m³ |

| Pump head: | 50 m | |

| Power: | 3 kW | |

| Plate heat exchanger: | Model: BP2-JB-4 | |

| Flow: 2000 L/H | ||

| Temperature change: 30°C → 85°C | ||

| SUS304 Stainless steel structure | ||

| EPDM sanitary pad, SUS316 plate | ||

| Alkali liquid pump: | 50 L/H | |

| Acid liquid pump: | 50 L/H | |

| Pipe fittings: | SUS 304 | |

-

PIPE WORKS

-

DEPALLETIZING MACHINE

FEATURES:

- Pallet conveying system designed for low-position loading, capable of pre-storing two pallets. The structure is crafted from carbon steel with a plate thickness of 3.0 mm.

- Main depalletizing section for layer-by-layer depalletization of loaded pallets. The frame features a stainless-steel structure, and the inner guiding boards on three sides are 1.5 mm thick SUS plates.

- High-position platform with a net conveying system, measuring 4.0 meters in height, 1.2 meters in width, and 3 meters in length. The structure is stainless steel, and it utilizes a low-friction plastic steel mesh chain.

- Conveying system for empty pallet discharge at a low position, constructed from carbon steel.

- Loaded pallet lifting system with a carbon steel structure.

- Electric-driven bottle pushing mechanism with a carbon steel structure.

- Platform for placing separating card-board, constructed from stainless steel.

- High-position operating platform and ladder with a carbon steel structure.

- Electric cabinet and cable wire trunking made from stainless steel.

- The machine operates using an electric-driven control method, with the lifting process monitored and automatically controlled by an electric eye for precise positioning. The electric eye monitors empty bottles, facilitating automatic pushing onto the high-position conveyor.

- Dimensions: 8500*2200*3200mm

Technical parameters:

| Model: | XD-4000 |

| Capacity: | 20000 C/H |

| Main material of the machine: | Stainless steel |

| Main lifting motor: | 1.5 kW |

| Bottle pushing motor: | 0.37 kW |

| Loaded pallet feeding motor: | 0.75 kW |

| Bottle conveying motor: | 0.75 kW |

| Air consumption: | 500 NL/min |

| Workshop minimum height: | 6000 mm (recommend install the machine at a low position with around -2000mm of the production line’s running height) |

Component list:

| Items | Supplier, Origin |

| Contactor | Schneider, France |

| Intermediate relay | |

| Switch | |

| Thermal relay | |

| PLC | Siemens |

| HMI | |

| Photoelectric sensor | Omron, Japan |

| Proximity switch |

-

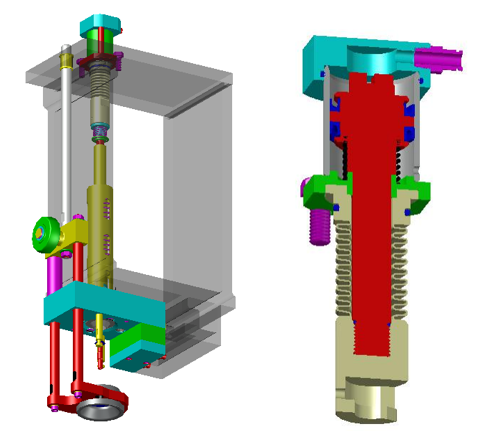

FILLING & SEALING MACHINE

Features:

- Welded by SUS304. Product contact is SUS304 food grade;(SUS316 for option)

- High-efficiency rinsing-nozzles can spray water to any part inside the bottle;

- Corrosion-resistant bearings from NSK or SKF;

- Electronic filling valves

- Open design for gear transmission;

- Equipped with VFD control, more energy-saving;

- PLC+HMI control system is equipped;

- All electric components are supplied by the world-famous companies;

Technical parameters:

| Model: | GD-32-6 |

| Capacity: | 20000 B/H (340ml) |

| Can height: | 120-310 mm |

| Can diameter: | 55-66 mm |

| Can height: | 70-165 mm |

| Filling pressure: | 0.25-0.35Mpa |

| Filling heads: | 32 heads |

| Filling method: | Isobaric filling |

| Filling temperature: | 85°C |

| Sealing heads: | 4 heads |

| CO2 consumption: | 8 Nm3 / h |

| Compressed air consumption: | 0.5Nm3/ h (0.4~0.5MPa) |

| Installed power: | 6 kW |

| Dimension: | 3000*2200*2500mm |

| Height of conveyor: | 1200 mm |

| Weight: | 5800 Kg |

Component list:

| Items | Supplier, Origin |

| PLC | Siemens, Germany |

| Touch screen | |

| Contactor | Schneider, France |

| Thermal relay | |

| Switches | |

| Photoelectric electric sensor | Omron, Japan |

| Pneumatic components | SMC, Japan |

| Bearing | SKF, Sweden |

- Filling part:

The system employs a blend of electronic filling and mechanical valves, preserving the liquid level control by maintaining the length of the return air pipe. The electronic filling structure encompasses vacuum, back pressure, and pressure relief, contributing to a straightforward design and responsive control. This approach not only reduces manufacturing costs but also enhances filling accuracy. By adopting the electronic filling control method, a flexible and programmable control system is achieved, mitigating the wear and potential failures associated with mechanical valves.

- The valve design adheres to a mature structure, optimizing redundancy to prevent instability in the filling effect caused by excessive machining accuracy resulting from a large cylinder diameter.

- A flexible buffer structure is implemented to prevent the air valve needle gasket and the air valve needle from rigidly contacting the sealing surface of the liquid valve. This mitigates the common issue in domestic equipment where the air valve needle bends, leading to severe seal damage.

- All seals are sourced from Danish Aveco Sealing Technology Co., Ltd. Both raw materials and finished products are eligible for FDA certification, ensuring a high level of sealing effectiveness and compliance with food safety and hygiene standards.

- Seaming Part

Description:

The sealing roller is crafted from a high-hardness alloy (HRC>62), and its sealing curve undergoes precise machining through optical curve grinding to guarantee optimal sealing quality and the smooth operation of the machine.

The machine features a tank under the cover and a control system that ensures the absence of a tank under the cover to maintain the machine’s normal operation and minimize lid loss.

Aluminum lids are manually fed into the machine.

The capping machine’s height is adjustable to accommodate cans of varying heights.

-

BOTTLE PASTEURIZING MACHINE

Description:

The warming tunnel serves the purpose of bringing bottles to room temperature, eliminating condensation on their surfaces to preserve taste and ensure the quality of labeling and packaging processes. Different temperature water is sprayed onto the bottles in various temperature regulation zones to gradually raise their temperature. The warming area is segmented into five sections, with temperatures increasing as bottles progress through these sections. As the bottles exit the tunnel, they attain room temperature.

Features:

- The conveyor system is highly reliable, featuring a flexible and convenient shifting mechanism.

- The conveyor belt for bottle transport is a robust plastic chain net with high strength and wear resistance.

- The main drive employs a continuously variable motor, enabling easy adjustment of the conveyor belt’s conveying speed.

- An efficient water spraying system is in place.

- The machine strategically arranges atomizing nozzles on the top of the chain plate to evenly spray water onto the bottles, ensuring optimal utilization and extensive coverage.

- The temperature control system is sensitive and user-friendly.

- This machine incorporates a temperature control system with high precision and a responsive interface for easy temperature adjustment.

Technical parameters:

| Model: | WPJ-8-10 |

| Capacity: | 20000 C/H |

| Material: | SUS304 |

| Motor power: | 0.75 kW |

| Dimension: | 18000*1500*1550 mm |

| Weight: | 3600 Kg |

| Steam consumption: | 300 Kg/H |

| Air pressure: | 0.7 Mpa |

-

CAN DRYING MACHINE

Description:

- The blower adopts a fan as the air source.

- An air knife type structure, and the size of the sealing can be adjusted.

- The top side and the two vertical sides of bottles can be blown to dry thoroughly.

- Easy for labeling, printing, packing operations.

Technical parameters:

| Model: | CGJ |

| Capacity: | 20000 C/H |

| Length: | 800 mm |

| Dimension of the blower: | 40*40 mm |

| Power: | 7.5 kW * 2 |

| Material: | Stainless steel 304 |

| Dimension: | 1200*350*1400 mm |

-

VACUUM LEAK PRESSURE TESTER

Description:

The real-time monitoring of internal pressure in cans and PET bottles post-liquid nitrogen filling ensures prompt detection and rejection of substandard products, accompanied by audible and visual alarms. Users can oversee the normal operation of the front-end equipment, preventing adversely affected products from entering the market. In cases of consecutive substandard products, the warning system alerts the front-end equipment promptly, allowing operators to set automatic equipment stoppage if needed to minimize losses. Furthermore, the detector facilitates convenient debugging of liquid nitrogen machine filling amounts, enabling judgment of internal pressure compliance without compromising the tank body.

Features:

- The detection system is equipped with Siemens PLC for efficient operation.

- Utilizes a high-precision dynamic tracking sensor capable of detecting minute pressure changes.

- PLC calculations and comparisons yield timely judgment results.

- Provides real-time monitoring of each tested product.

Technical parameters:

| Model: | NYJ-200 |

| Detection head: | 1 |

| Production capacity: | 20000 cans/min |

| Using range: | Can diameter: φ52.5~φ99mm |

| Can height: H65~H166mm | |

| Power: | 150W |

| Dimension: | 530*150*350mm |

| Weight: | 40 Kg |

| Dimension: | 780*350*800mm |

-

LIQUID LEVEL TESTER

Description:

ZJZ200 filling liquid level detector is a liquid level detecting instrument developed by INPAKT to reach the advanced level at home and abroad. After the low-energy photon source interacts with the measured substance, the ray intensity changes according to the position of the detected material surface to control the volume of the filled liquid material. Due to its non-contact measurement method, the problem that the conventional weighing method cannot measure the volume of liquid material in the production line can be solved fundamentally.

Technical parameters:

| Model: | ZJZ200 |

| Production capacity: | 20000 cans/min |

| Using range: | Can diameter: φ52.5~φ99mm |

| Can height: H65~H166mm | |

| Power: | 150W |

| Dimension: | 530*150*350mm |

-

DATE BATCH CODER

Features:

Speed without compromising quality:

- Ideal solution for a range of slow to moderate speed applications:

- Single line maximum speed of 162 m/min (533 ft/min)

- Two line maximum speed of 59 m/min (194 ft/min)

- Three line maximum speed of 29 m/min (96 ft/min)

- Store up to 100 complex messages for easy recall. Store even more messages using a standard USB memory stick

- Small and portable, the 1220 is easily moved from line to line with minimal connections

Engineered to keep your line running:

- Videojet’s advanced core technology includes all ink system filters and common wear parts

- Intervals of up to 9,000 hours between preventative maintenance

- Auto cleaning printhead for fast start-ups, even after extended shutdowns

- Optional internal air pump eliminates need for external air, minimizing potential for contaminants to enter the ink stream

No mess, no waste fluid delivery:

- Advanced fluid management reduces makeup consumption to as low as 2.4 ml/hr

- Smart CartridgeTM fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

Simple Usability via Videojet standard CIJ interface:

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and maintenance

- Prompted user fields to help reduce errors.

Technical parameters:

| Model: | VJ1240 |

| Line speed capability: | Can print 1 to 3 lines of print at speeds of up to 533 ft./min. (162.5 m/min.) (10 characters per inch, single line of print) |

| Font Matrix Configuration: | 5×5, 5×7, 7×9, 11×16, 17×24 |

| Twin-line: | 5×5, 5×7, 7×9 |

| Tri-line: | 5×5, 5×7 |

| Nominal Character Height: | Selectable from 0.079’’ (2 mm) to 0.279’’ (8.5 mm), depending on font 230 Kg |

| Throw Distance: | Optimal: 0.472’’ (12 mm)

Range: 0.197’’ (5 mm) to 0.591” (15 mm) |

| Keyboard: | Membrane style with tactile feedback, including 72 numeric, alphabetic, and special function keys. PC-style layout to approximate international PC convention. |

| Display: | 320×240 Bright blue backlit 5.7’’ LCD display. WYSIWYG onscreen message editing |

| Custom Logo/Graphics: | Can be created by individual user on printer or PC with optional Videojet |

-

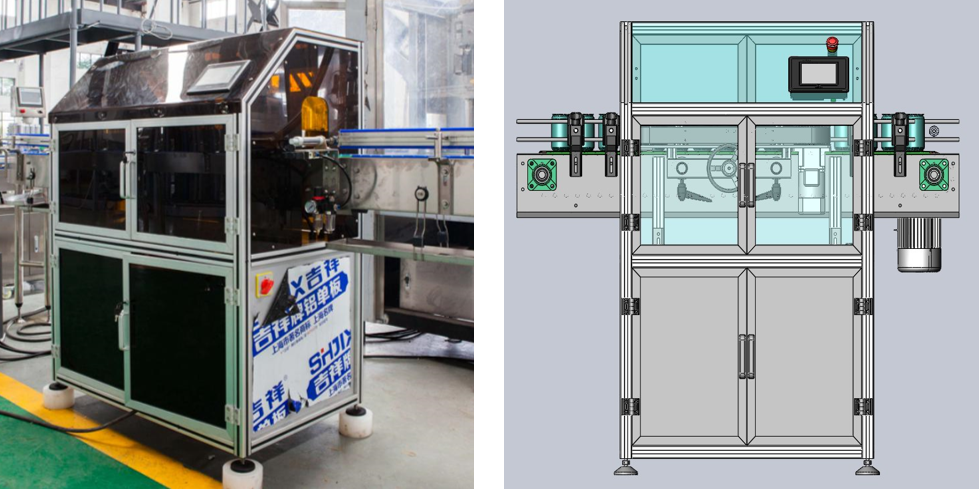

AUTOMATIC HIGH-SPEED SHRINK PACKING MACHINE

Features:

- Cylinder with a suction device, cardboard grasping mechanism, cardboard failure rate reduced down to 0.5%.

- Unique open-design for cardboard storage system, efficient cardboard feeding, large cardboard storage space.

- Shrinking chamber uses a unique circular air supply technology to achieve multi-directional air flow control, adjustable air flow speed, adjustable outlet position, greatly improved shrinkage effect.

- Distance between the individual cooling tunnel and shrink tunnel longer than 500 mm, cooling effect sufficiently, greatly reduced the interaction between hot air and cold air, for energy-saving.

- Tray folding mechanism introduced into four driving chains, quick product changeover time, 30 minutes reduced upon traditional type.

- The whole machine designed with energy-saving technology, saves 30% power consumption, low-carbon and environment-protection.

- Modular design for easy maintenance.

Technical parameters:

| Model: | YCBS30 |

| Capacity: | 25 package/min |

| Sealing time: | 0.5-1.5s; 0-0.5s |

| Shrink film: | PE/PET/POF film |

| Power supply: | 65 kW |

| Conveyor loading: | 30 Kgs |

| Working voltage: | Three-phase-five line 380V/50Hz, 40KW

Control voltage: DC24V |

| Working pressure: | 0.6~0.8Mpa (without oil without water) |

| Air consumption: | 380-400NL/min |

| Pipe Joint Size: | Φ12 |

| Shrink chamber: | L*W*H=2400*650*450(mm) |

| Shrink temperature: | 130℃~230℃ |

| Width of film roll: | ≤580mm |

| Thickness of film: | 0.06~0.10mm |

| Diameter of film roll: | ≤300mm |

| Tray requirements | three layers of corrugated cardboard |

| surface roughness and thickness | 5mm |

| Working noise | ≤80dB |

| Total weight | 6000 Kg |

Electric Components

| Items | Supplier, Origin |

| Servo motor &control system | B&R, AUSTRIA |

| PLC | B&R, AUSTRIA |

| Touch-screen | B&R, AUSTRIA |

| Hot melt glue machine | NORDSON, AMERICA |

| Transducer | Schneider, FRANCE |

| Contactor | Siemens, GERMANY |

| Intermediate relay | Schneider, FRANCE |

| Press adjusting device | Airtac, TAIWAN |

| Approach switch | LEUZE, GERMANY |

-

BELT CONVEYOR & BUFFERING SYSTEM

Description:

The operational efficiency of a production line hinges largely on the configuration of the conveyor line. This configuration must account for short-term shutdowns of rear-end equipment (e.g., label replacements) without disrupting the front-end equipment. It should seamlessly connect both ends to optimize the overall production line efficiency. Our production line layout prioritizes the balance between customer investment and production line efficiency, achieving these goals with advanced global technology. The mechanical structure features a new design, with components predominantly formed through stamping or bending, offering advantages such as robust rigidity, lightweight construction, and excellent interchangeability. The transmission method ensures reliable operation and convenient maintenance, suitable for conveying bottles with diameters ranging from Ø40 to Ø110mm. The electric control system employs PLC (On the Rinsing-filling-capping tri-block) to oversee the entire container conveying buffer system, automatically handling functions like running speed acceleration, deceleration, and buffering.

Features:

- The bottle belt synchronously tracks with the host or upstream/downstream equipment, all controlled by the central system.

- Conveying process ensures no bottle falls, jams, or blocks.

- A buffer platform can be configured in front of the labeling machine (typically with a buffering time of 1-2 minutes) as per user requirements.

- During PE label replenishment, the filling process continues, storing filled bottles on the buffer platform. Once PE label replenishment is complete, the labeler initiates labeling, resuming synchronized production.

- After replenishment, the labeling machine accelerates production to refill the platform with labeled bottles and then resumes the synchronized production speed.

- Modular design of the conveyor belt structure allows interchangeable parts, making it compact, low-noise, easy to install and maintain, with flexibility for different capacities and bottle types.

- Advanced and rational electric control design can be customized to customer requirements, selecting the necessary electrical control components to enhance transportation smoothness.

- Control switch positions are strategically set based on the conveying system layout or customer demands for user-friendly operation.

Technical parameters:

| Motor power: | 0.37 kW / 6m |

| Width of the conveyor: | 110 mm |

| Height: | 1050 mm |

| Thickness of the steel plate: | 2 mm(SUS304) |

| Bottle volume: | 200-3000 ml |

| Bottle Diameter: | 50-100 mm |